Chapter 3 Before positioning

3- 58

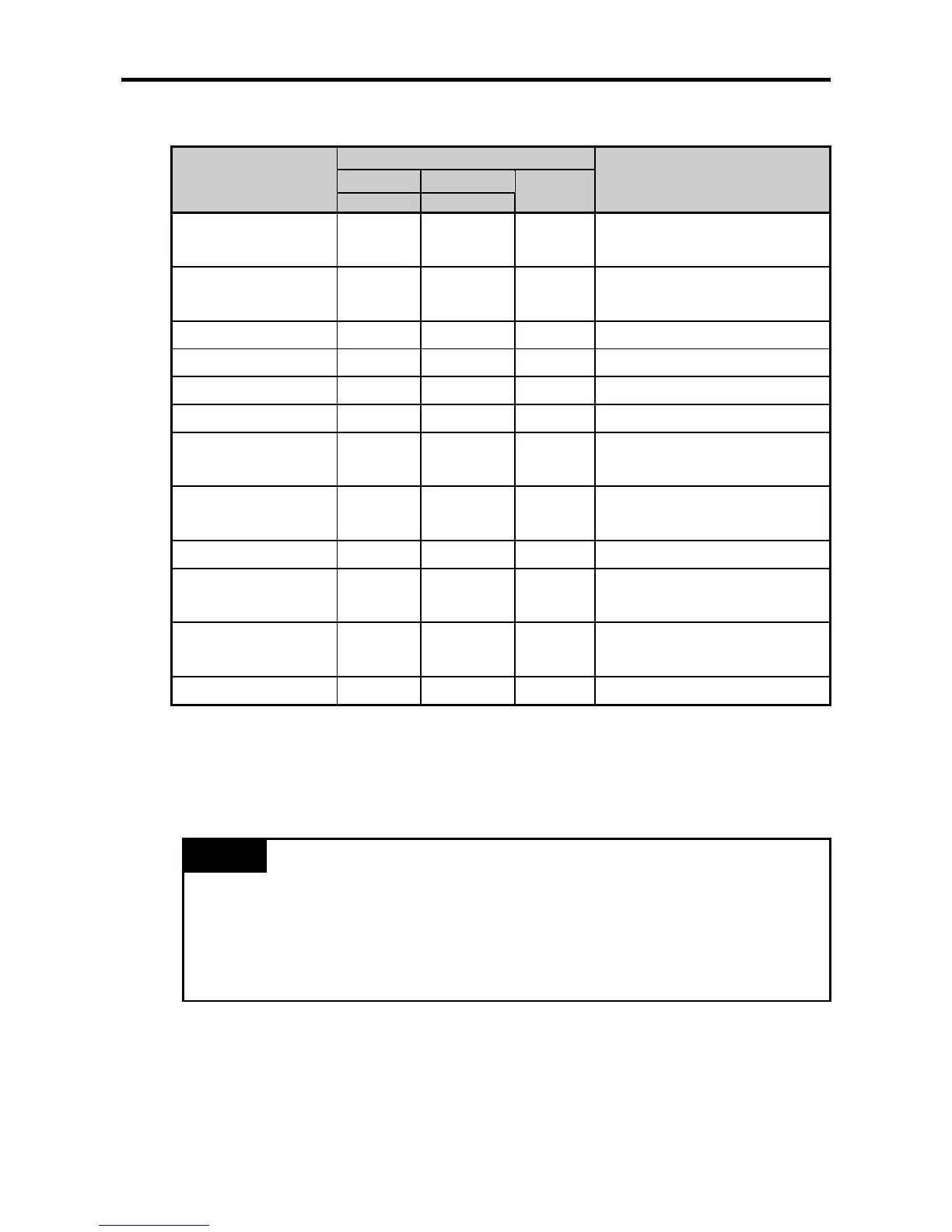

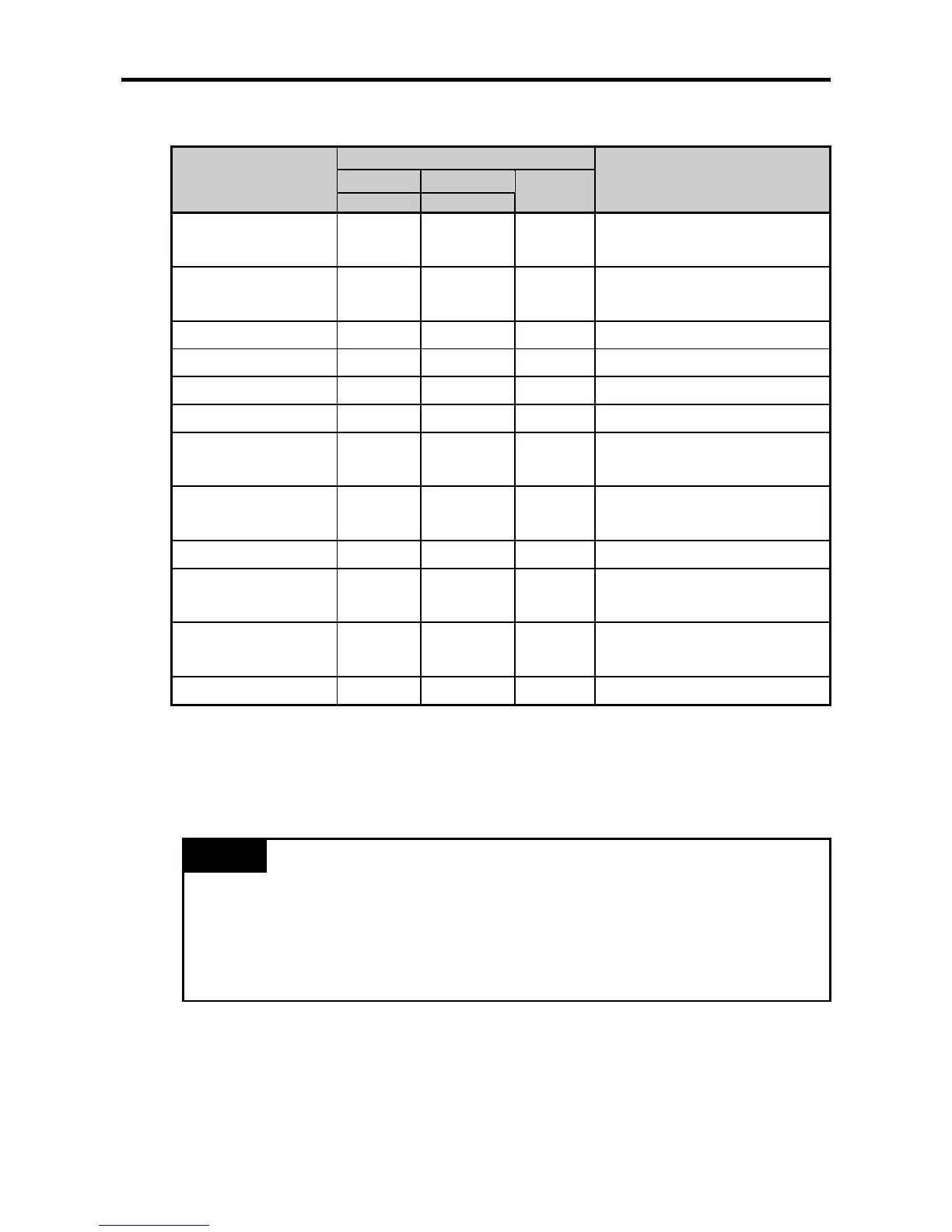

(b) In case of XBM/XBC (Step 01)

Variables

Device area

Status

Axis X Axis Y

properties

Address Address

Step 01 target position

%KD265 %KD415

Double

word

Step 01 operation speed

%KD267 %KD417

Double

word

Step 01 dwell time

%KW536 %KW836

Word

Step 01 M code number

%KW537 %KW837

Word

Step 01 operation method

%KX8608 %KX13408

Bit

Step 01 control method

%KX8609 %KX13409

Bit

Step 01 operation pattern

(Low)

%KX8610 %KX13410

Bit

Step 01 operation pattern

(High)

%KX8611 %KX13411

Bit

Step 01 coordinates

%KX8612 %KX13412

Bit

Step 01 acc./dec. number

(Low)

%KX8614 %KX13414

Bit

Step 01 acc./dec. number

(High)

%KX8615 %KX13415

Bit

Step 01 coordinates

%KW539 %KW839

Word

• The table above shows the area K for positioning of the operation step #1. You can change the

operation data without setting the parameters by changing the value of the corresponding area K.

• If you want to permanently preserve the operation data of the changed area K, apply the data of

current area K to the built-in parameter area by using the applied instruction (WRT instruction,

APM_WRT instruction).

Remark

• Note that area K for positioning is initialized if you cut the power and re-supply power or if you

change the operation mode without executing the WRT instruction after changing the value of

area K.

• The variable of area K for each step can be used more conveniently by using the variable

registration function of XG5000. For the positioning monitor registration, see the manual of

XG5000.

Loading...

Loading...