Chapter 5 Positioning Instructions

5 - 29

5.2.11 Speed Synchronous Instruction

• The speed synchronous instruction (SSS instruction) is for speed synchronization at the set

synchronous speed rate and operation when the main axis is started with the axis set in the

instruction being the auxiliary axis. For details, refer to 3.1.8.

(1) Speed Synchronous Starting Instruction (SSS)

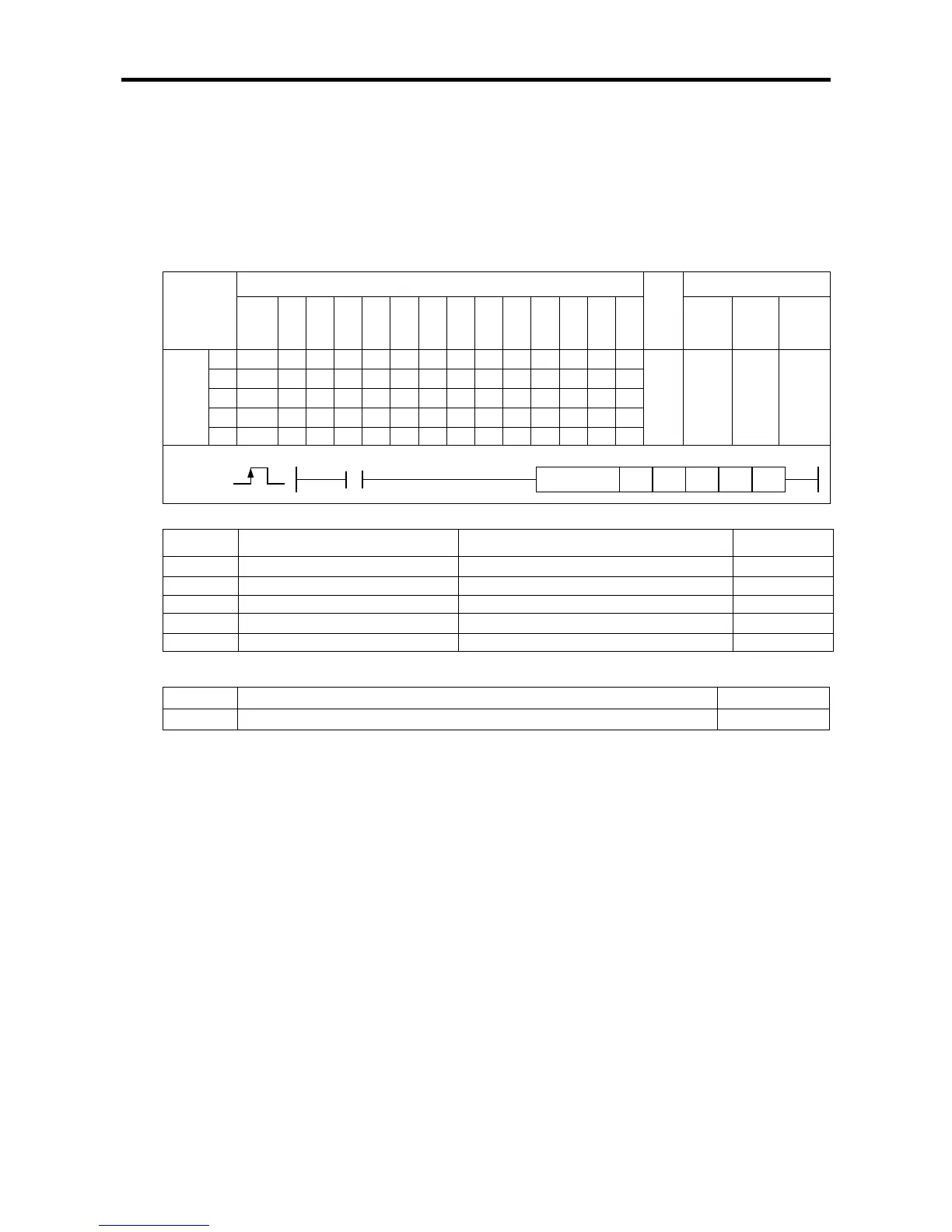

[Area Setting]

Operand

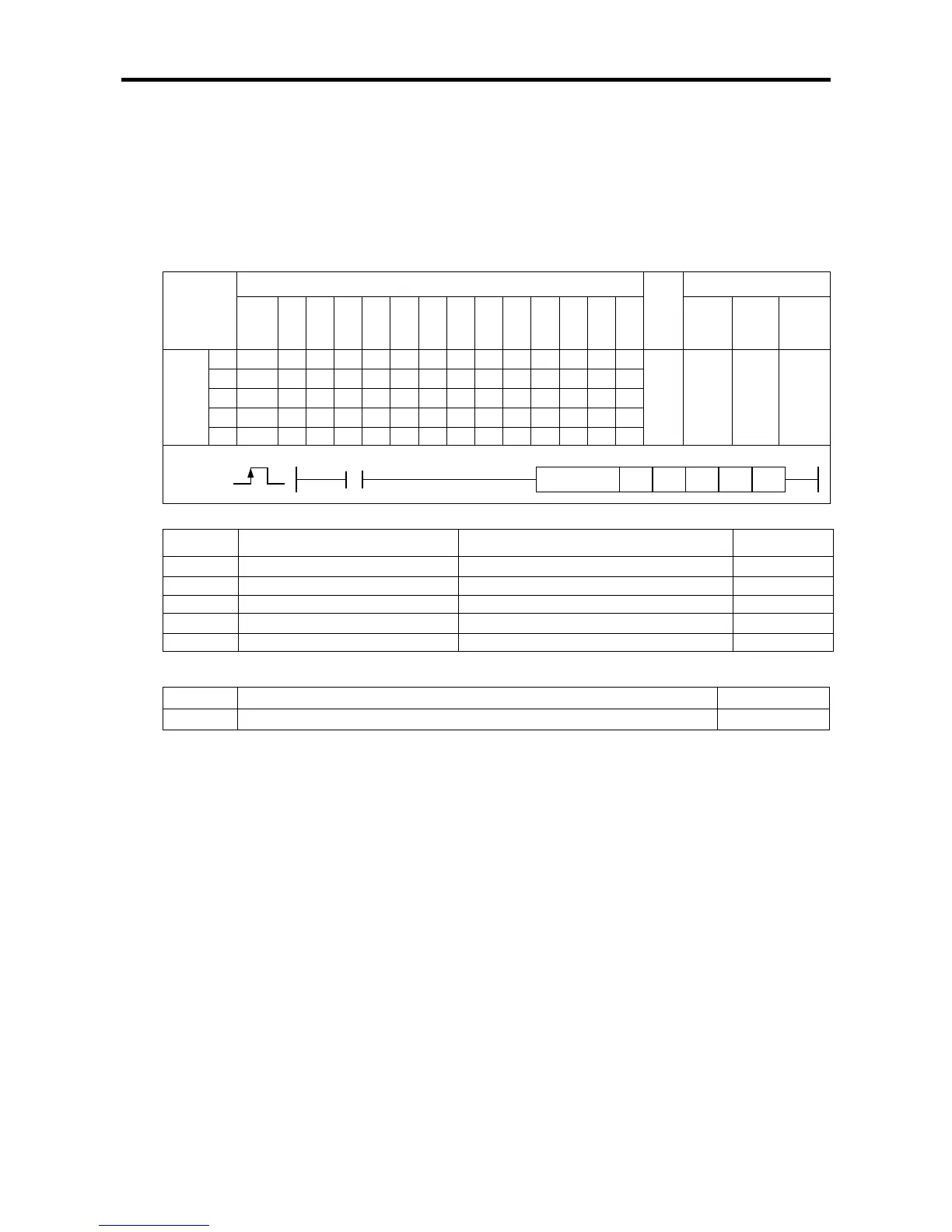

[Flag Set]

Flag Description Device number

Error If the value of ax gets out of the range F110

(a) Function

• This instruction is for executing the speed synchronous starting for synchronous starting.

• The axis set in the axis designated as ax at the rising edge of the input condition auxiliary axis, n3

becomes the main axis and the speed main axis position synchronous starting instruction is

executed.

• If the instruction is executed, the auxiliary axis stands by without generating actual pulse (the

operation status flag of the auxiliary axis (axis X:K4200, axis Y:K4300) turns On), and nn3 axis,

which is the main axis, it is started according to the speed synchronous ratio set in n1.

• The synchronous ratio settable in n1 is 0.01% ~ 100.00% (set value 1 ~ 10,000). If the set speed

ratio gets out of this range, error code 356 is issued.

• The delay time of n2 refers to the delay time it takes for speed of the auxiliary axis to reach the

current main axis speed. In XGB built-in positioning, when controlling the speed synchronization,

the speed of the current main axis is detected every 500 ㎲, and thereby the speed of the

auxiliary axis is adjusted. If the speed of the auxiliary axis is synchronized to the current main axis

speed without a delay time and immediately changed, there might be damage or shock noise to

the motor due to the sudden change of the auxiliary axis speed.

For example, assuming the speed ratio is 100.00% and the delay time is 5[ms], if the speed of the

main axis is 10,000[pps], the XGB built-in positioning adjusts the speed of the auxiliary axis

according to the speed of the main axis every 500[㎲] by adjusting the current speed for the

speed of the auxiliary axis to reach 10,000[pps].

The longer the delay time, the longer the delay time between the main axis and auxiliary axis, but

the output pulse is stably output. If there is likely to be step out of the motor, lengthen the delay

time.

Instruction

Areas available

Step

Flag

PMK F L T C S Z D.x R.x

con

stan

Loading...

Loading...