Chapter 5 Positioning Instructions

5 - 35

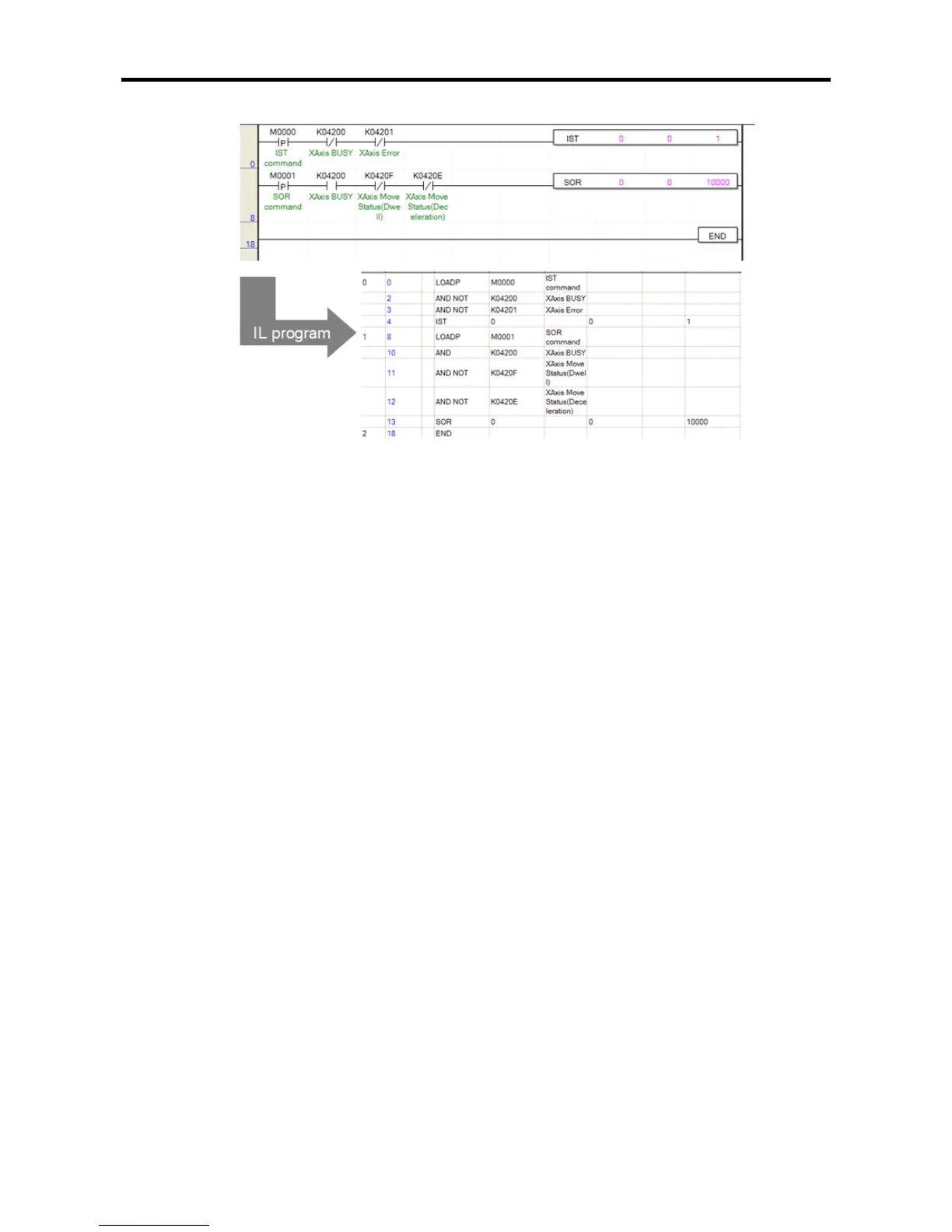

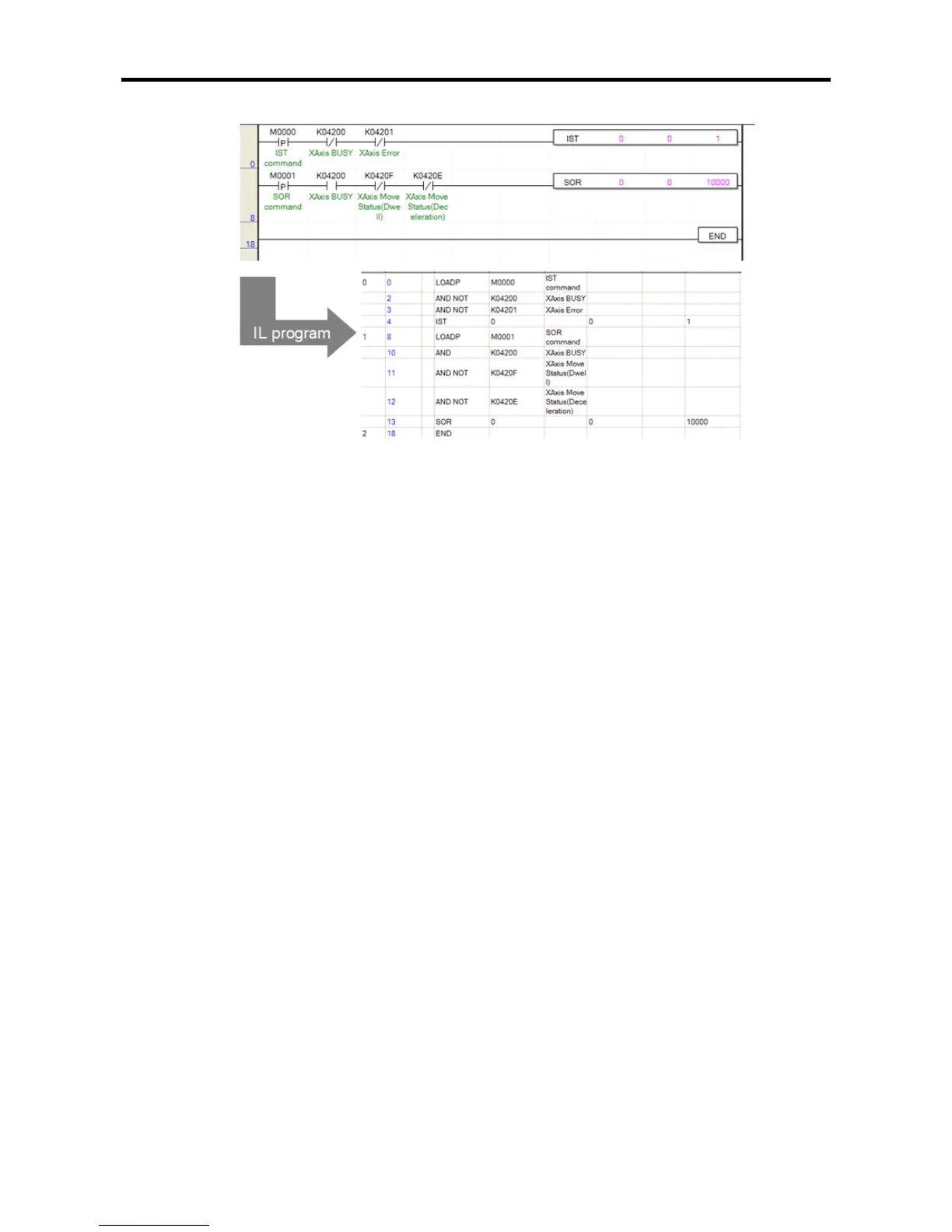

(a) Example of the Program

(b) Operation of the Program

• The positioning axis X is indirectly started with operation step 1 if there is the rising edge of M0000

used as the indirect starting instruction signal.

• If there is the rising edge of M0001 used as the instruction signal of the speed override instruction

during operation, operation continues by changing the speed of the currently operating step into

10,000[pps]. (Note that the value of the operation speed of No. 1 step set in the positioning

parameter is not changed)

• If the speed override instruction is executed during deceleration or dwell, error code 377 is issued.

To prevent this, make the program by connecting the axis X dwell flag to the starting contact point

with the normally closed contact point (contact point B).

Loading...

Loading...