84

SC100/200 Series Users Manual EM-6337-B Rev.15

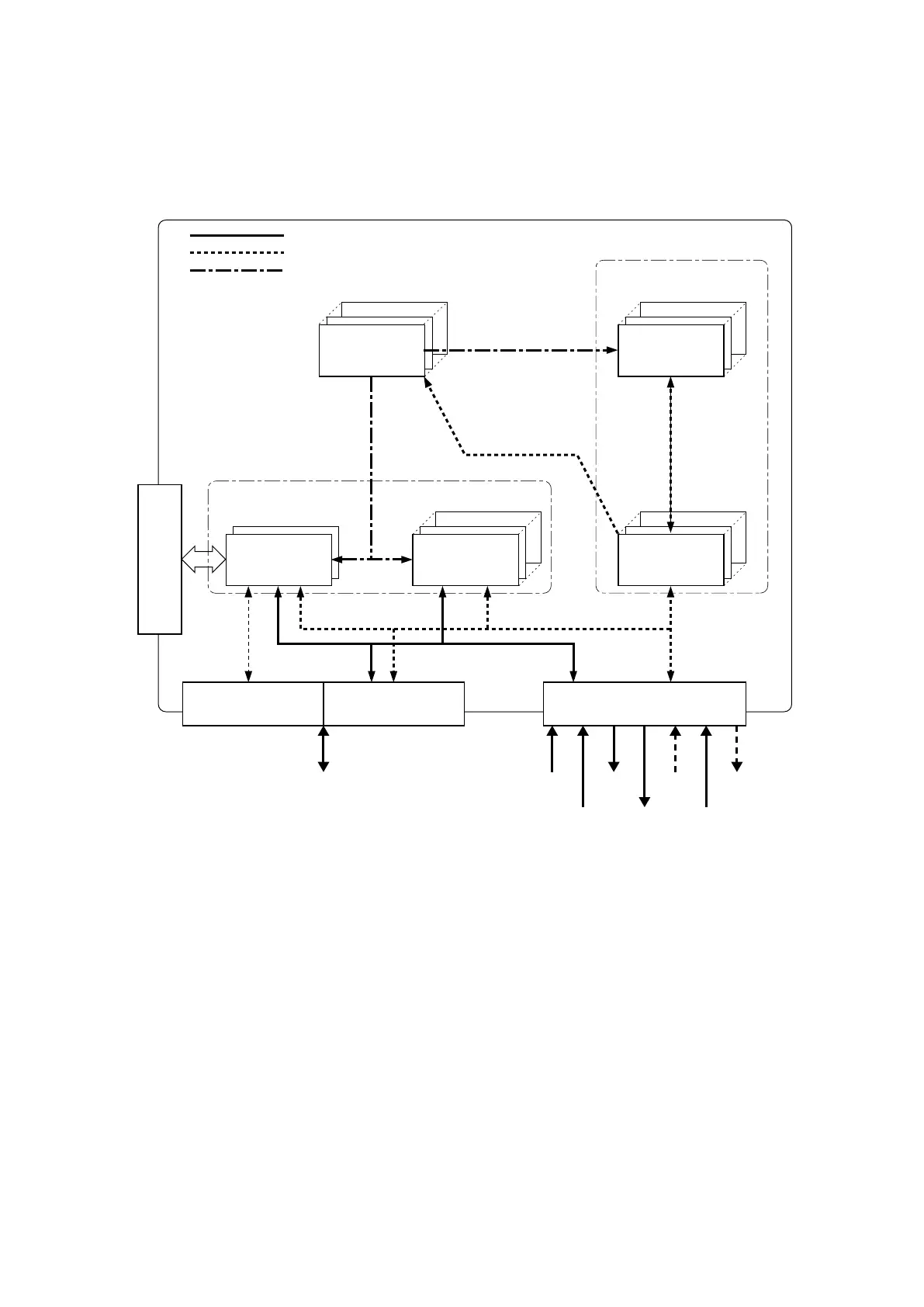

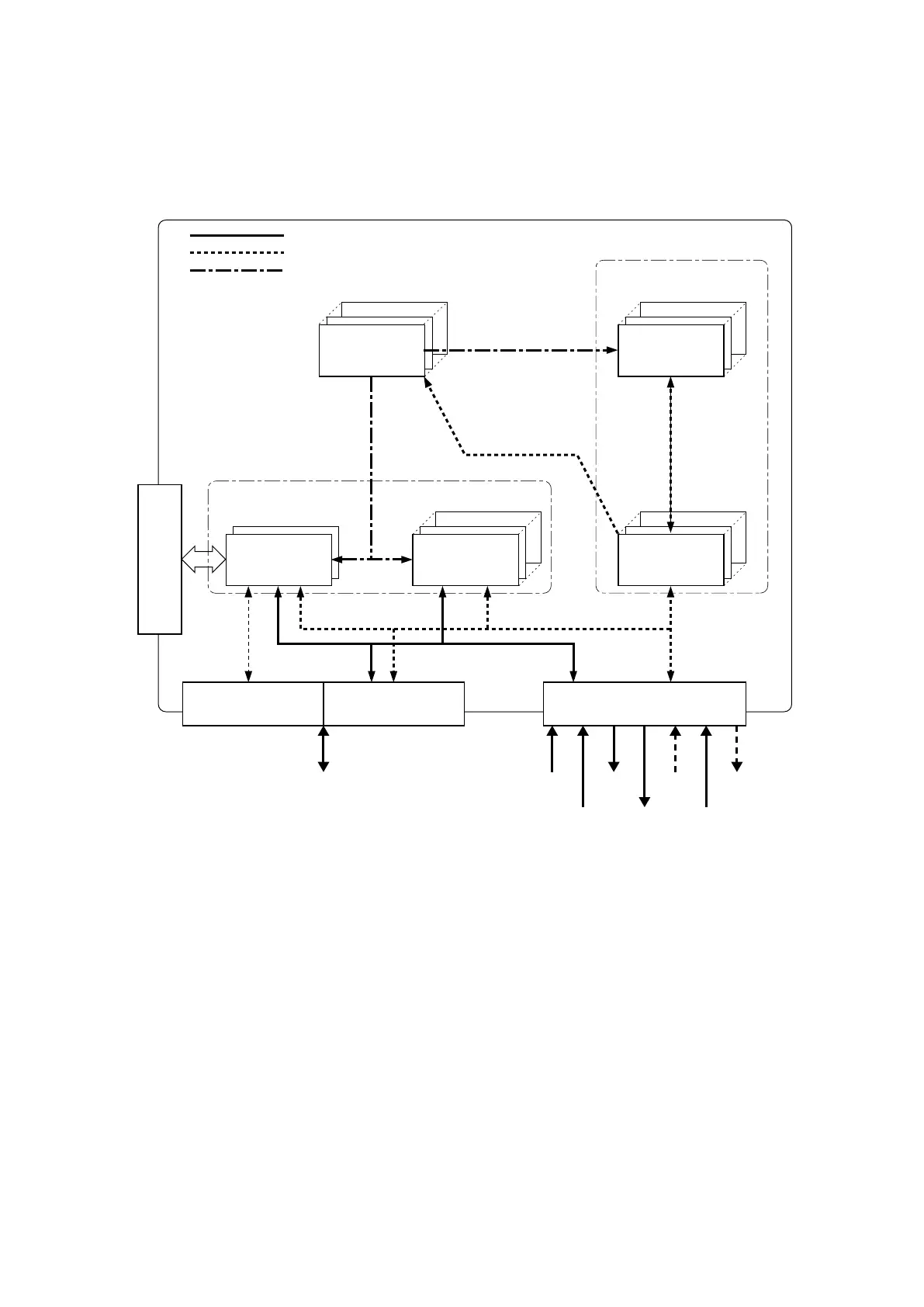

7.4. RELATIONS BETWEEN FUNCTION BLOCKS

• Close connection between PID control and sequential control

• I/O point expansion via software terminal blocks

• Automatic parameters and setpoints change via “Parameter Setter” block

OPERATION

BLOCKS

(parameter setting)

OPERATION

BLOCKS

(timer, counter, internal switch)

OPERATION

BLOCKS

(analog functions)

CONTROL

BLOCKS

(2 blocks available)

SEQUENTIAL

CONTROL BLOCKS

(12 blocks available)

LOOP CONTROL

(analog signal)

SEQUENTIAL CONTROL

(discrete signal)

Parameter Transmission

Command

FIELD TERMINAL BLOCK (1)

Analog Signal

Discrete Signal

Parameter Transmission

Pv 1, 2

Ai 1...4

COMMUNICATION

TERMINAL BLOCK (16)

LOOP

COMMUNICATION

Mv 1, 2NestBus, Modbus (SC200/210)

Ao 1, 2

Di 1...5

(Pi 1...5)

Pi 6

(Di 6)

Do 1...5

FRONT LCD DISPLAY

* Operation blocks:

32 + 8 large operation blocks + 8 batch programs

*

*

*

Sequence Control Command

Software WiringLoop Data for Host

Communication

Loading...

Loading...