91

SC100/200 Series Users Manual EM-6337-B Rev.15

9.2. AUTO-TUNING OPERATIONS

With all auto-tuning parameters set, choose ‘AT : Run Auto-tuning.’ If the selected reference tuning point (CV) value is greater

than the setpoint (SP), a message for caution appears on the screen to warn a possible damage to the control system.

Control output (MV) is changed in a step between 100% and 0%. PV amplitude (Kcp) and frequency (Tcp) are measured

to calculate appropriate PID parameters. When MV high limit (MH) is set to a value lower than 100% and/or low limit (ML)

to one higher than 0%, MH and/or ML values are used for oscillation. Fix MV at 0% when the control action (DR) is set to

‘1 : Reverse (MV decreases with increasing PV);’ or at 100% when it is set to ‘0 : Direct,’ and wait until PV is stable enough

before starting auto-tuning procedure.

The following example of the Controller operation is applied to reverse control action.

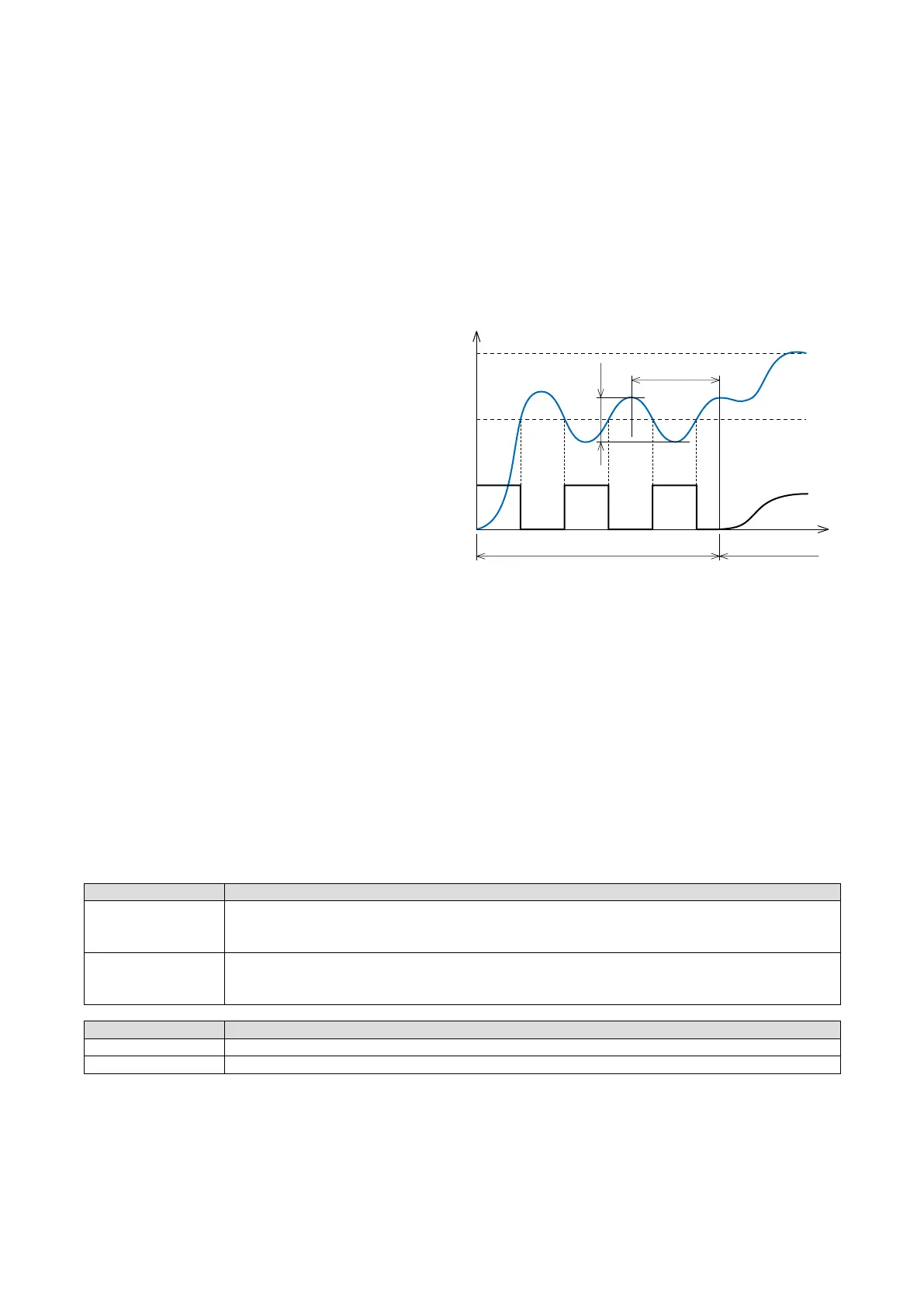

1) Blue AUTO indicator starts blinking. MV is switched to 100% and then to 0% when PV crosses across CV.

2) MV is then again switched to 100% when PV crosses

across CV the second time. These cycles are re-

peated for twice.

3) Amplitude (Kcp) and frequency (Tcp) of the reacting

PV waveform as in the gure to the right are meas-

ured.

4) P, I and D parameters are obtained from the following

formulae using Kcp and Tcp values. The a, b and c

values depend upon optimization and control action

settings.

Proportional gain: K = a Kcp

(Proportional band : PB = 100% / K)

Integral time: TI = b Tcp

Derivative time: TD = c Tcp

5) Store the calculated parameters and go back to nor-

mal PID control mode. Green AUTO indicator is turned on.

When the auto-tuning procedure is completed abnormally as explained in the following, ‘MI : Fixed MV’ at error value is ap-

plied as MV.

• When PV goes over PV high limit or below PV low limit.

• When the procedure does not complete before preset time out (TO) is elapsed.

• When ‘AT : Stop Auto-tuning’ is selected (a message for caution appears on the screen).

9.3. OPTIMIZATION & CONTROL ACTION

OPTIMIZATION DESCRIPTION

Process change (= Constant-value control)

PID parameters are calculated so to suit PV signal change (disturbance). Choose this option for single loop

control and for primary loop control in a cascade control loop.

Setpoint change (= Follow-up control)

PID parameters are calculated so to suit SP signal change.

Choose this option for secondary loop control in a cascade control loop.

OPERATION MODE DESCRIPTION

PID P, I and D parameters

PI P and I parameters

SP

CV

PV

MV

100%100% 100%

0% 0%

Tcp

Kcp

Auto-tuning in progress PID control

t

The above figure shows operation with reverse control action.

MV cycles are inverted with direct action.

Wait to start the procedure until PV is stabilized.

Loading...

Loading...