IMPULSE

®

•G+ & VG+ Series 4 Technical Manual

November 2020

Page 217

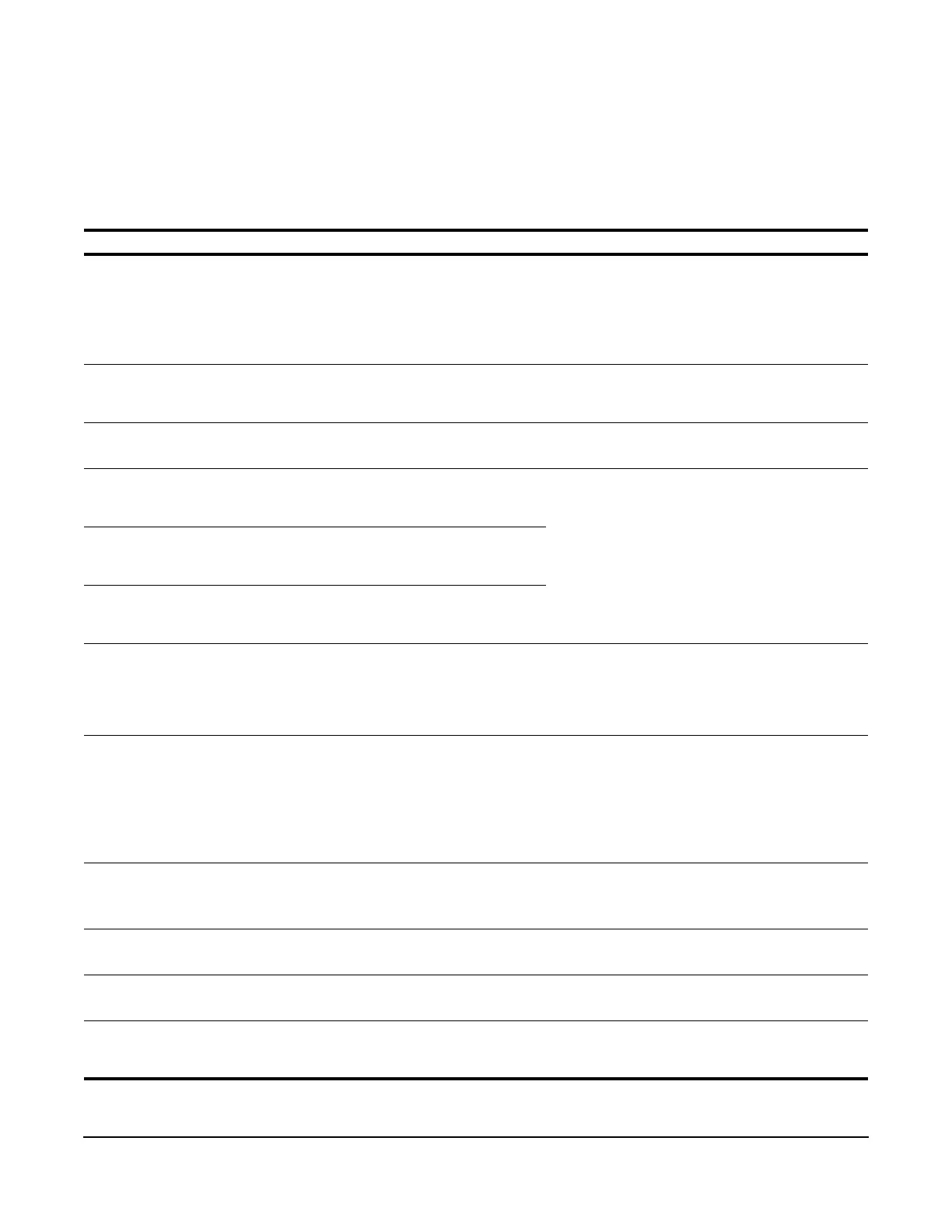

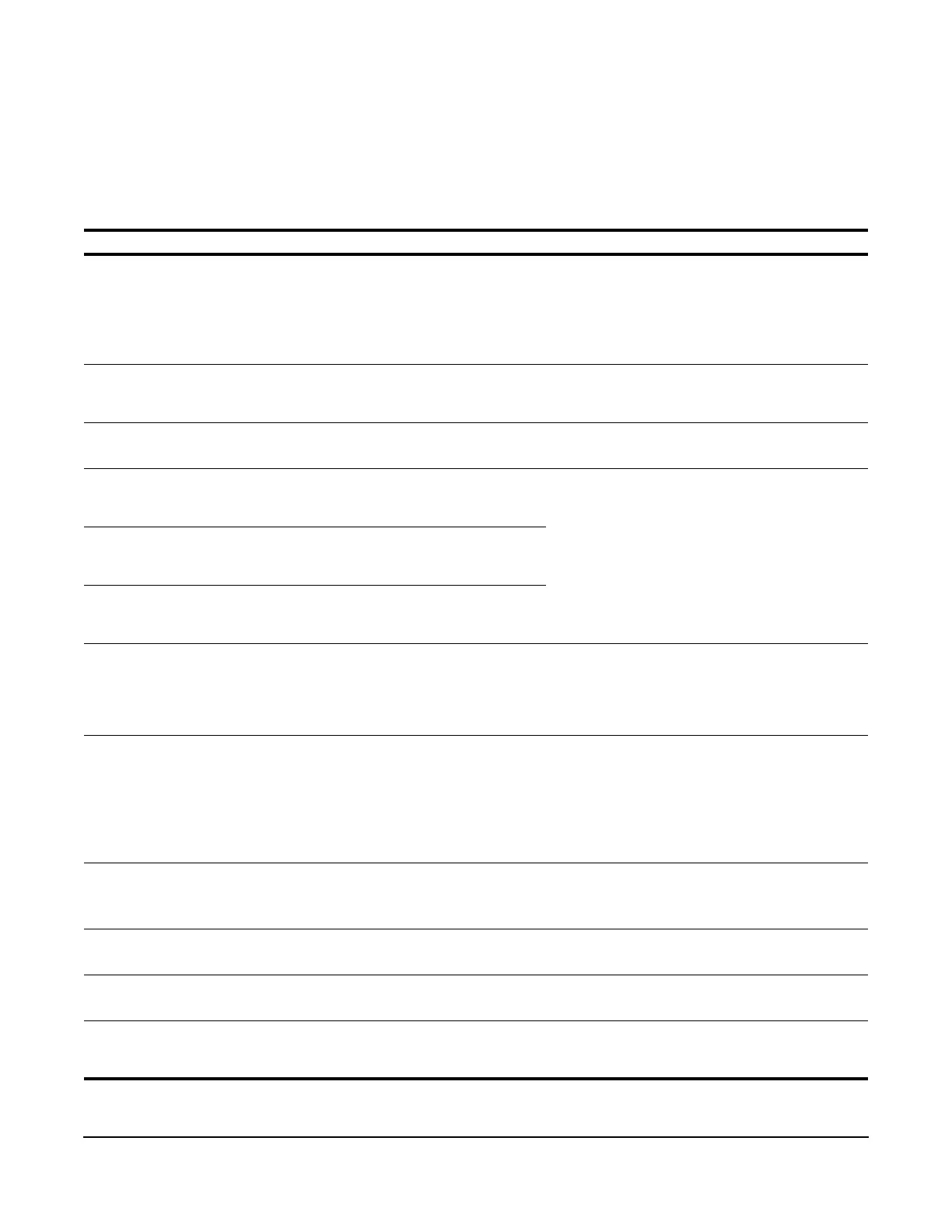

6.3 Fault Display and Corrective Actions at Auto-Tuning

The following are fault displays and corrective actions at auto-tuning. If any of the following faults are found, the

keypad displays that fault contents; the motor coasts to stop if it is under operation. Fault contact output or minor

fault contact output does not operate.

Table 6-5: Fault Display and Corrective Actions

Fault Display Fault or Indicator Name/Description Corrective Action

Er-01

Fault

Motor Data Fault. Motor data input fault for auto-

tuning. Relationship between motor output and

motor rated current fault. Relationship between

input motor rated current and set no-load current

fault (at vector control method and line-to-line

resistance tuning.)

• Check input data.

• Check VFD and motor capacity.

• Check motor rated current and no-load current.

Er-02

Minor Fault

Alarm. The minor fault is detected during auto-

tuning.

• Check input data.

• Check wirings.

• Check load.

Er-03

STOP Key

STOP Key Input. The stop key is pressed during

auto-tuning.

Er-04

Resistance

Line to Line Resistance Fault. Auto-tuning is not

completed within the expected time. The auto-

tuning is outside the parameter setting.

• Check input data.

• Check motor wiring.

• If a motor and a load are connected, disconnect

the motor from machinery system.

Er-05

No-Load Current

No-load Current Fault. Auto-tuning is not

completed within the expected time. The auto-

tuning is outside the parameter setting.

Er-08

Rated Slip

Rated Slip Fault. Auto-tuning is not completed

within the expected time. The auto-tuning is

outside the parameter setting.

Er-09

Accelerate

Acceleration Fault. The motor did not accelerate

at the expected time.

• Increase B05-01 (acceleration time).

• If C07-01 and C07-02 (torque limit value) are

decreased, increase values.

• If a motor and a load are connected, separate

the motor from the load.

Er-10

Motor Direction

Motor Direction Error. The encoder signal lines

are not properly connected to the VFD; the motor

direction and PG direction are opposite; or the

load pulled the motor in the opposite direction of

the speed reference and the torque exceeded

100%.

• Check and correct wiring to the PG encoder.

• Check the motor speed monitor U01-05 while

manually turning the motor forward. If the sign

displayed is negative, change the setting of

parameter F01-02.

• Uncouple the motor from the load and restart

Auto-Tuning.

Er-11

Motor Speed

Motor Speed Fault (Rotation type tuning only).

The motor speed was over 100% at auto-tuning

(flux vector control without PG only).

• Increase B05-01 (acceleration time).

• If a motor and a load are connected, separate

the motor from the load.

Er-12

I.det.Circuit

Current Detection Fault. Current exceeded the

motor rated current.

• Release brake.

• Check for open motor lead.

Er-13

Leakage Inductance

Leakage Inductance Fault. Auto-tuning did not

finish within the set time.

• Check the T1 parameters.

• Check motor wiring.

End 1*

V/f Oversetting

Excess V/f setting (Rotation type tuning only).

The torque reference exceeded 100% and no load

current exceeded 70%.

• Check the T1 parameters.

• Disconnect the motor from the load.

Loading...

Loading...