McHale Fusion 2 drive systems section

13-15

McHale Fusion 2 round baler wrapper technical service manual

Issue 1: 0208

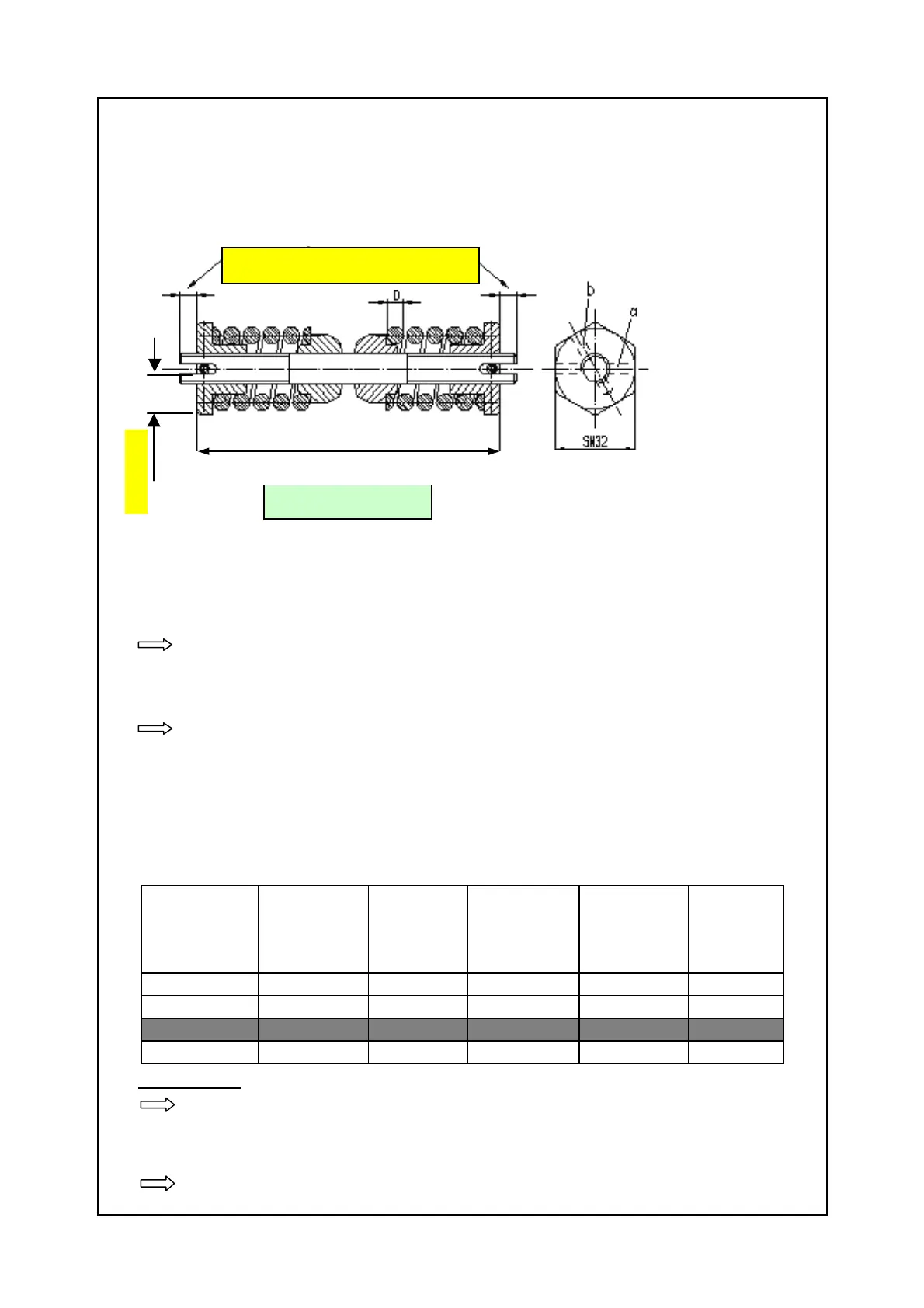

13.7 Slip clutch setting

CAUTION

To avoid blocking of the clutch, it is important to take care that during setting and also for re-

adjustment the shortest spring pack length is not fallen short of. After re-adjustment, the spring-

type straight pins must be re-inserted into the drilled passages of the hexagon nuts.

Grease with special grease (graset 116 or 147) only.

Subsequent torque adjustment

of cam-type cut-out clutches

K 64/1 and K 64/2

GKN Walterscheid GmbH sets all clutches exactly to the specified torque.

The spring pack is pre-set according to the specified torque. Pre-setting is done at the

factory by determining the spring resistance.

The

torque setting may only be adjusted

by a professional shop and after

consultation with the implement manufacturer. Torque adjustment based on the

setting applied at the factory requires even screwing-on or unscrewing of the nuts

(SW 32).

If the torque is re-adjusted several times, it is no longer possible to check the

setting correctly. In this case, the torque setting either has to be checked by

means of an appropriate measuring device or directly at GKN Walterscheid

GmbH.

If a re-adjustable spring pack is installed, remove the spring-type straight pins (Item a).

Determine the existing spring pack length based on the sketch. Then re-adjust

according to the following table.

CAUTION

To avoid

blocking of the clutch

, it is important to take care that during setting

and also for

re-adjustment

the shortest spring pack length is not fallen short of.

After re-adjustment, the spring-type straight pins must be re-inserted into the

drilled passages of the hexagon nuts.

Grease with special grease (Agraset 116 or 147) only.

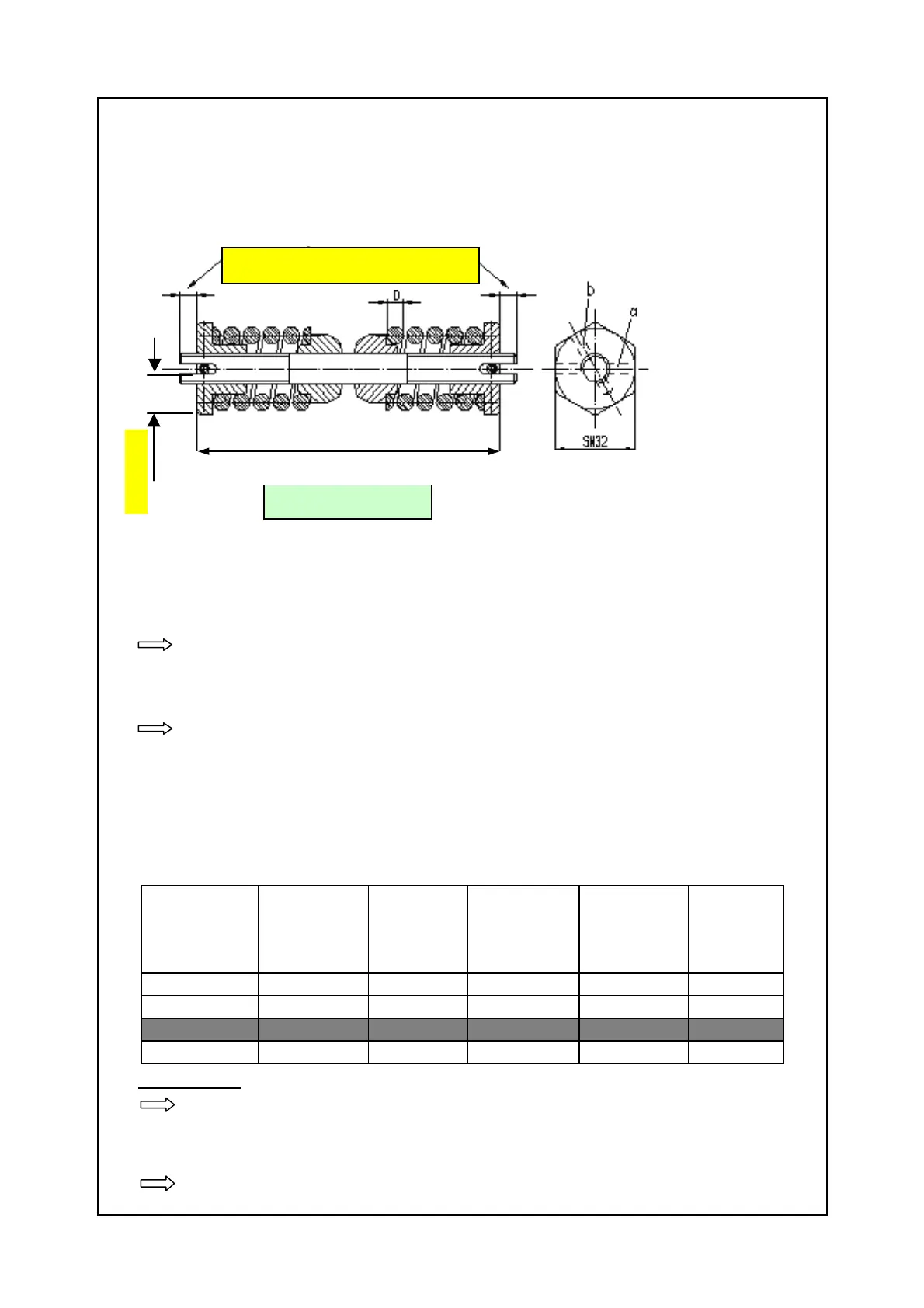

Adjust to same projection

Spring pack length

M10x1

Spring pack

version for

clutch type

Clutch OD Dia. of

spring wire

"D"

Adjustment by

1 mm

Shortest

permissible

spring pack

length

Spring pack

length

K 64/1 130 mm

14.0 daNm 89 mm

K 64/2 170 mm 6.5 mm 8.5 daNm 116 mm

K 64/2 170 mm 7.0 mm 10.0 daNm 119 mm 123mm

K 64/2 170 mm 7.5 mm 14.0 daNm 119 mm

Loading...

Loading...