Revision:1.0(2023-01-12)

161

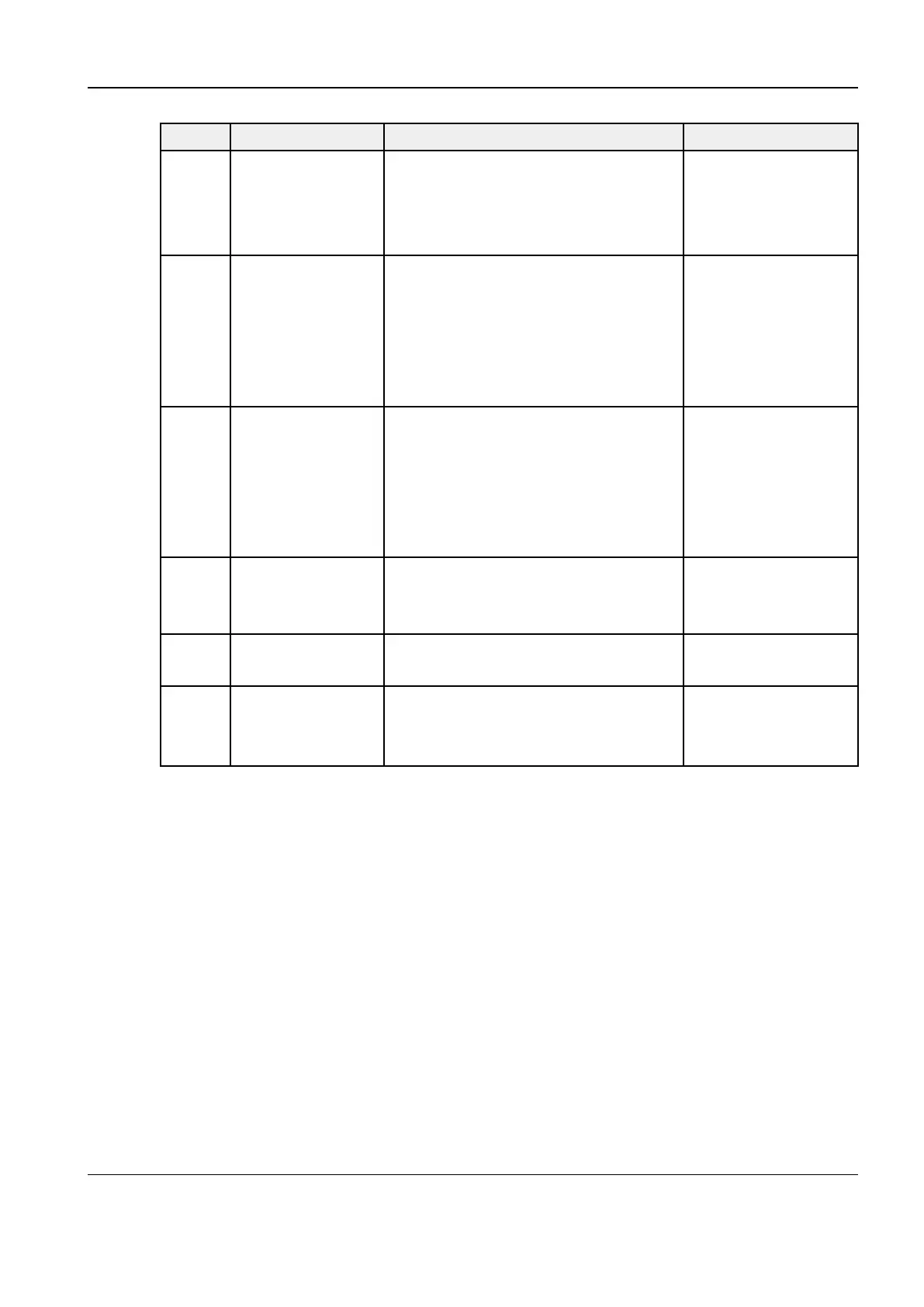

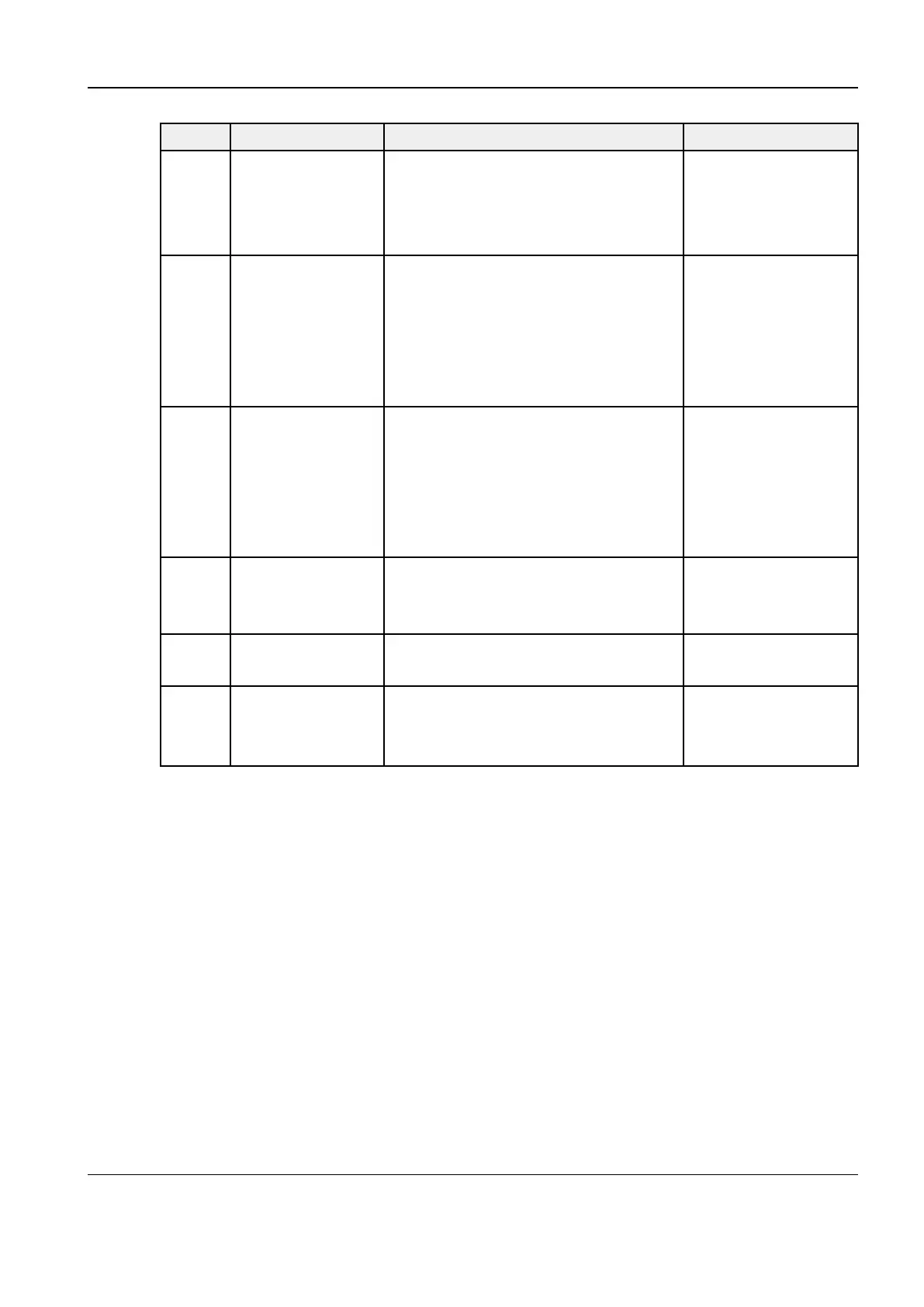

Item Content Method Tool

1 Caster Visually check that the casters are not

broken. Turn on and off the caster locks

to ensure that casters can be locked

and released properly.

None

2 Caster connection

Visually check that the casters are not

askew and whether the connecting

screws do not crack or fall off. Use a

wrench for the inspection, and check

that the casters and the base

connection screws are not loose.

Socket head wrench

3 Handle Visually check that there are no cracks

in the front and rear handles of the

machine. Hold the rear handle with

both hands, push the machine, and

gently pull it to confirm that the rear

handle is not loose.

Socket head wrench

4 Trolley supporting

parts

Pull the trolley supporting table by hand

to confirm that the entire trolley support

is not loose.

5

Shell of the main

unit

Visually check that the shell does not

crack.

/

8 Other mechanical

structures

Check that no other structural parts are

loose, the shell does not crack, and no

conductive parts are exposed.

None

55..11..33..55 Electrical Safety Inspection

Electrical safety inspection must be carried out by maintenance engineers with specialized

knowledge or skills or by engineers trained to have such skills.

For details, see 9.4

Electrical Safety Maintenance.

Diagnostic Ultrasound System

Service Manual

5 Maintenance

Loading...

Loading...