5

SETTINGS AND PROCEDURES BEFORE OPERATION

5.12 Maintenance and Inspection

5.12.2 Periodical inspection

5 - 61

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

FUNCTIONS

5

SETTING AND

PROCEDURES

6

I/O NUMBER

ASSIGNMENT

7

MEMORIES AND

FILES

8

INSTALLING /

UNINSTALLING

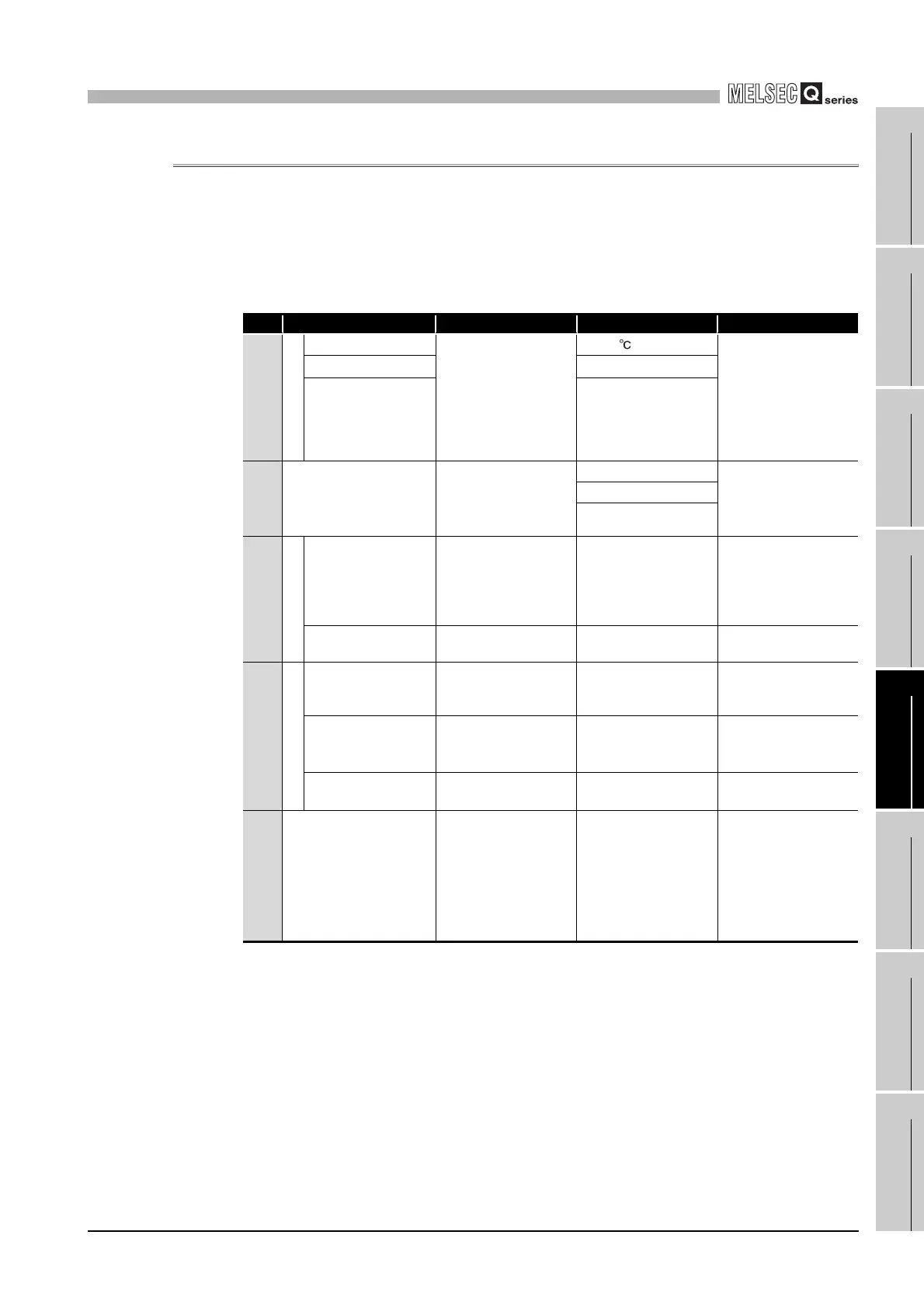

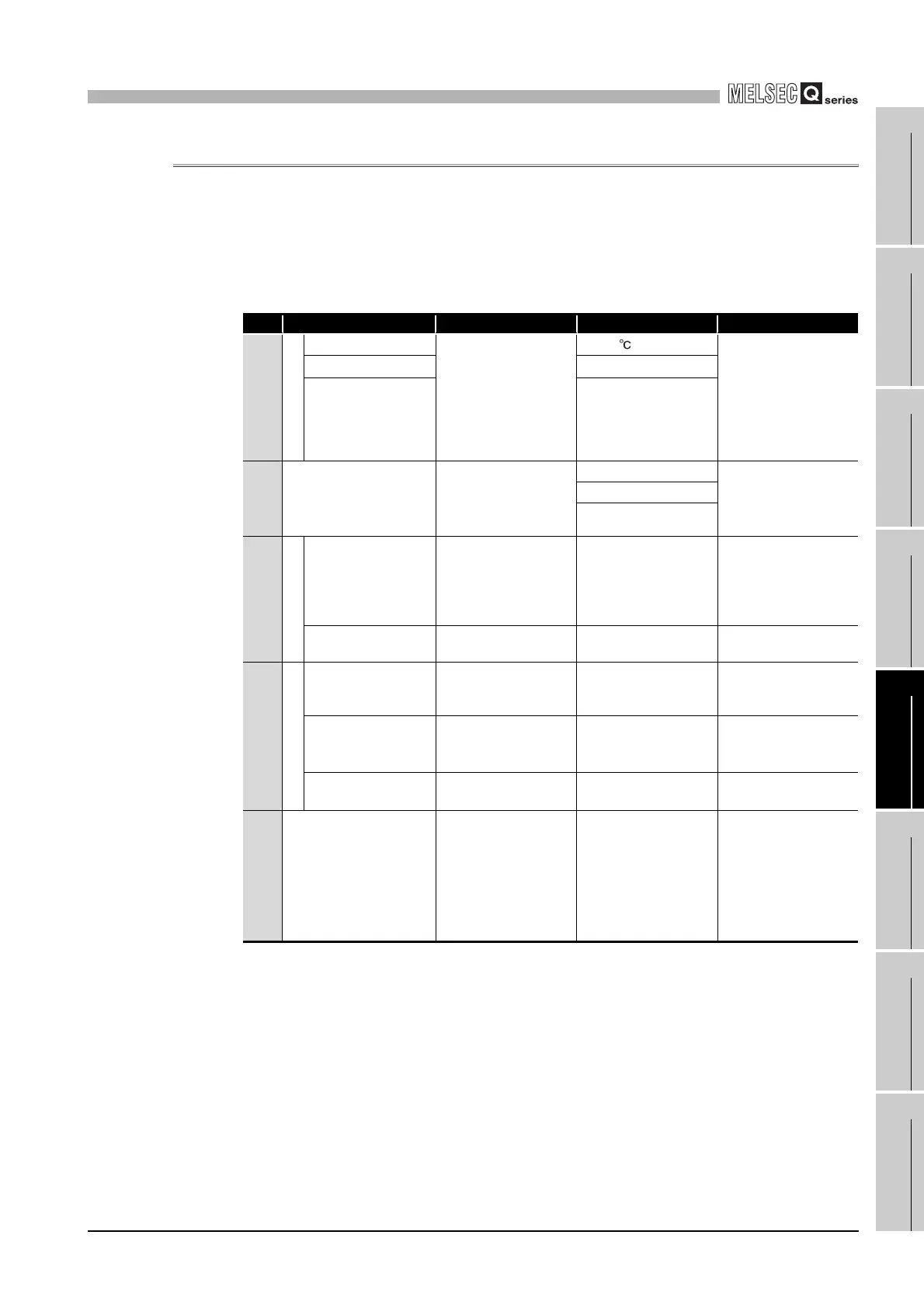

5.12.2 Periodical inspection

This section explains the items to be inspected once or twice every six months or every

year.

Note that these inspections must be implemented when the system is moved or modified

or when the wiring is changed, for example.

* 1 It should be 10 to 90%RH when an AnS series module is used in a multiple CPU system.

Table5.15 Periodic inspection

Item Inspection Item Inspection Criteria Remedy

1

Ambient environment

Ambient temperature

Measure with a

thermometer and a

hygrometer.

Measure corrosive gas.

0 to 55

When the module is

used in the panel, the

temperature in the

panel becomes the

ambient temperature.

Ambient humidity

5 to 95%RH

*1

Atmosphere

Corrosive gas must not

be present.

2 Power voltage

Measure a voltage

across the terminals of

100/200VAC and

24VDC.

85 to 132VAC

Change the power

supply.

170 to 264VAC

15.6 to 31.2VDC

3

Installation

Looseness, rattling

Move the module to

check for looseness

and rattling.

The module must be

installed fixedly.

Retighten the screws.

If the C Controller

module, I/O, or power

supply module is loose,

fix it with screws.

Adhesion of dirt and

foreign matter

Check visually.

Dirt and foreign matter

must not be present.

Remove and clean.

4

Connection

Looseness of terminal

screws

Try to further tighten

screws with a

screwdriver.

Screws must not be

loose.

Retighten the terminal

screws.

Proximity of

solderless terminals

to each other

Check visually.

Solderless terminals

must be positioned at

proper intervals.

Correct.

Looseness of

connectors

Check visually.

Connectors must not be

loose.

Retighten the connector

fixing screws.

5 Battery

Check that "Battery

error" turns off on the

<<Module

information>> tab of the

C Controller setting

utility.

(Preventive

maintenance)

Even if the lowering of a

battery capacity is not

shown, replace the

battery with a new one

if a specified service life

of the battery is

exceeded.

Loading...

Loading...