Motion 2000 TSSA Description

1-2 Manual # 42-02-1P21

The job prints accompanying your Motion 2000 controller are the primary document necessary

to install the controller and additional equipment (if ordered from MCE). The job prints and

this manual together provide the information necessary to install, adjust, and troubleshoot the

Motion 2000 elevator controller. Study the job prints and read the manual before installing and

adjusting the controller. Call Motion Control Engineering with any questions you may have

before beginning installation or start-up.

Your Motion 2000 system may include:

•Car controller: Distributed-processor, elevator control configured according to a customer

job survey.

• Car top station: Interface/interconnect/control box between car-mounted equipment and

the car controller.

• Car top junction box: Some jurisdictions require that circuit boards normally mounted

inside the Car top station be mounted in the car controller cabinet instead. In these

instances, the less complex car top junction box is used in place of the car top station.

• Car station: Car operating panel interface.

• Dispatcher: If the car is part of a group, dispatching components and software may be pro-

vided.

Motion 2000 provides:

• Low-rise hydraulic building application

• Performance up to 200 feet per minute

• Up to 32 single or double-openings

• Simplex, duplex or group control

•Extensive field programmability

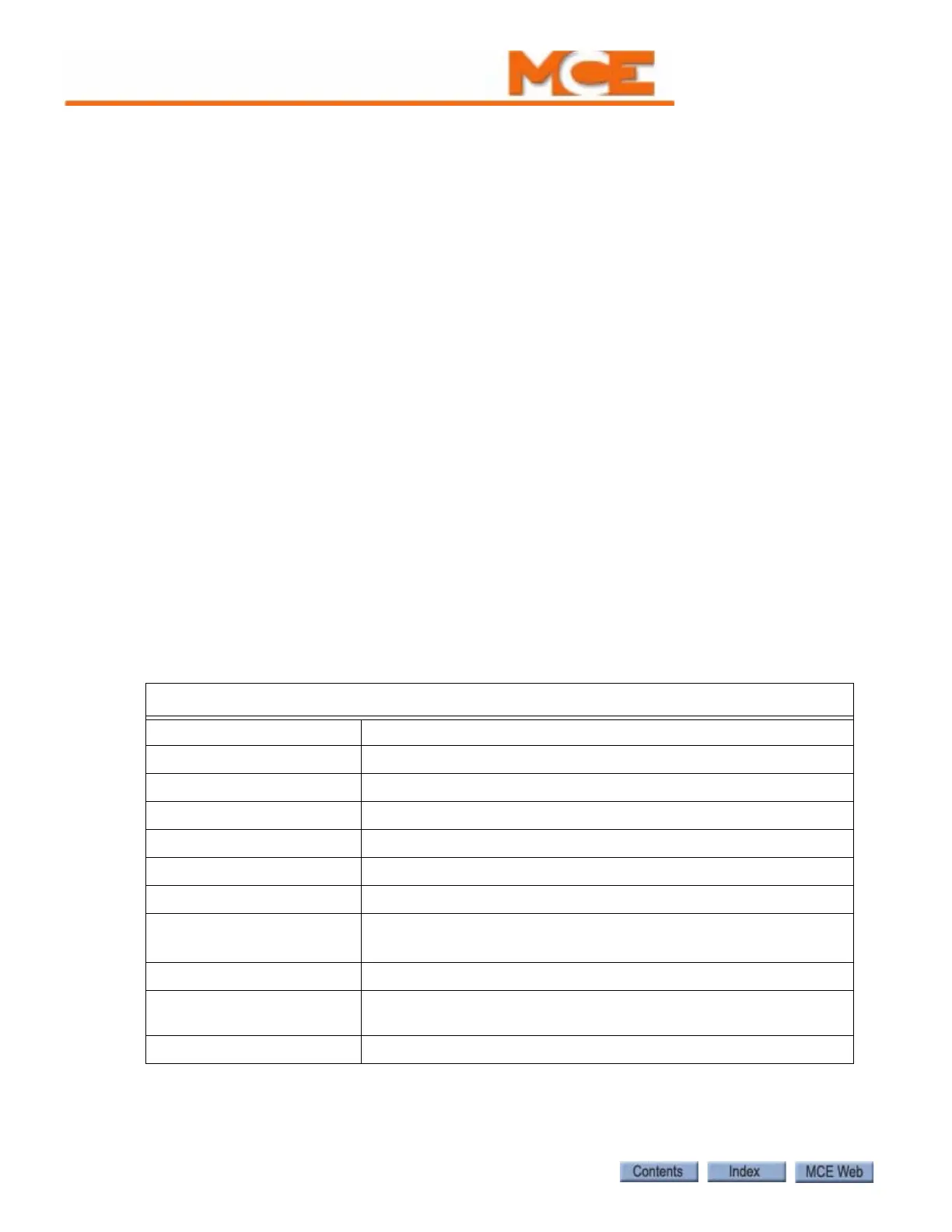

Motion 2000 Hydraulic Controller Specifications

Maximum car speed 200 fpm, 1.0 mps

Configuration Simplex, Duplex, Group

Landings Up to 32

Motor control Solid State, Y - Delta or Across the Line

Landing system LS-QUTE (solid tape/magnets), LS-STAN (vanes), LS-EDGE

System access LCD and switches, hand-held user interface or PS/2 keyboard

Dispatching Groups to six cars

Environment

32-104

o

F, 0-40

o

C, humidity non-condensing up to 95%;

harsh environment rugged service available (NEMA 4, 4X, 12)

Standard enclosure 34” w x 31.5” h x 11” d (864 x 800 x 380 mm) includes knock-outs

Optional enclosure

(feature dependent)

36” w x 42” h x 9” d (914 x 1067 x 305 mm) includes knock-outs

Input 208-600 VAC, 50/60 Hz, single or 3-phase

Loading...

Loading...