Startup - Inspection Operation

3-4 Manual # 42-02-1P21

Set Up for Construction Operation

If required, it is possible to run the car during construction to help complete work in the hoist-

way. In this mode, the car runs at inspection speed. If they are in place, cartop controls may be

used or the car may be run from the controller or a temporary run box. (Please refer to “Tempo-

rary Run Box Hookup” on page 3-6.)

Required Connections

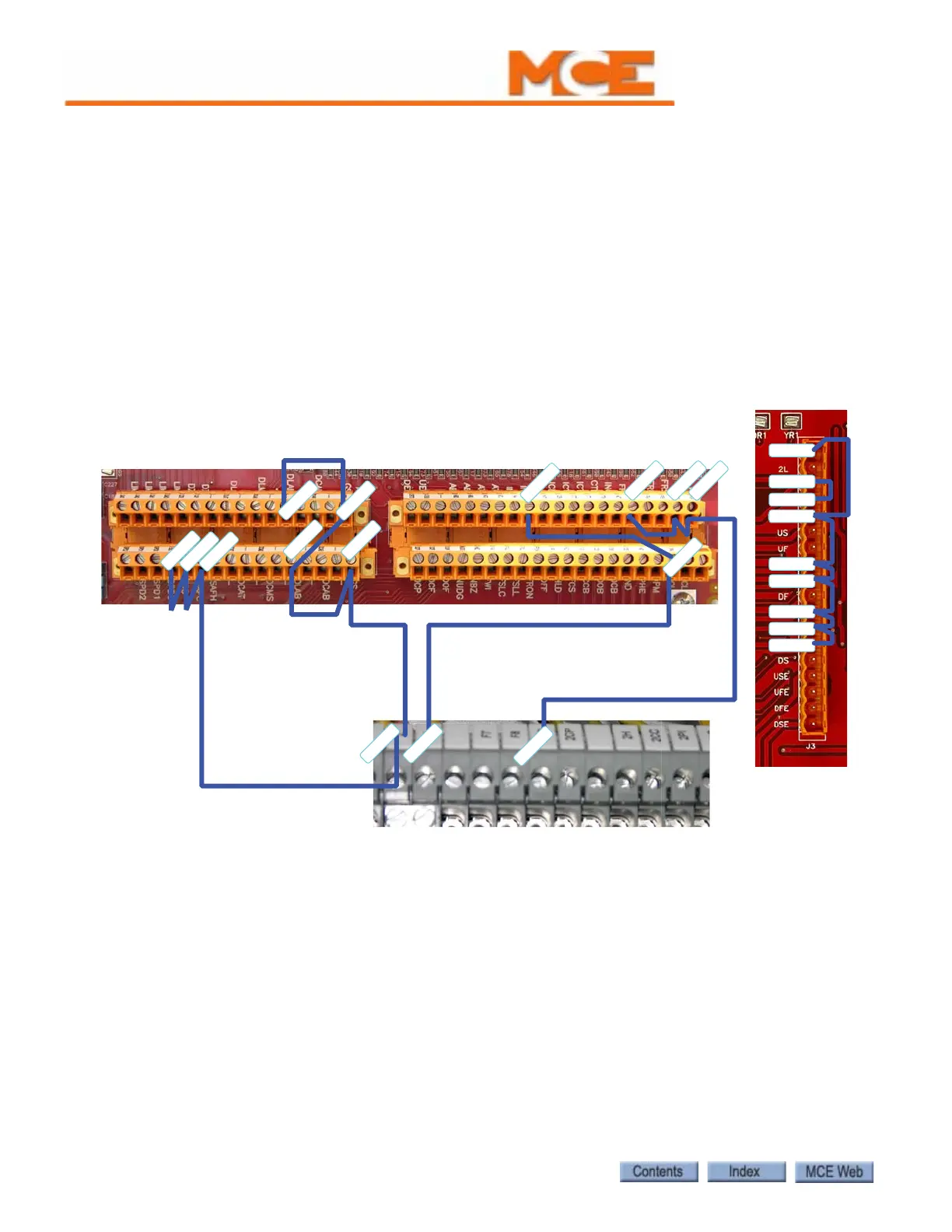

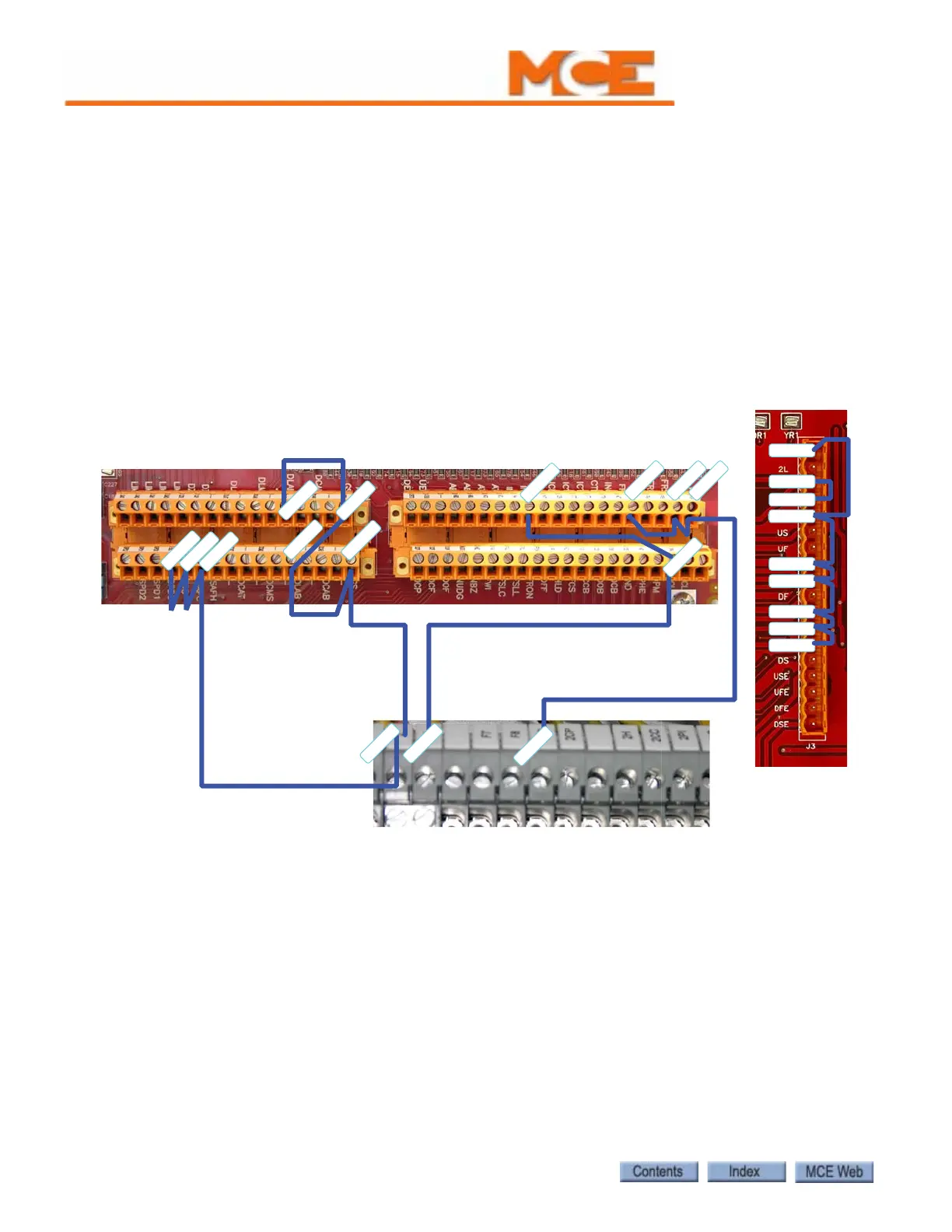

Please refer to “Construction Mode Jumper Requirements” on page 3-5 and to the following

illustration and text.

Figure 3.1 Jumpers Used Before Final Equipment Connected

Minimal equipment requirements are:

•Pump motor and valves.

• SAFH, SAFC, ESC: Hoistway and car safety devices. Connecting 2 bus to these terminals

(as described in Table 3.1) will cause relay SAFS on the HC-CTL-2 board to pick and light

the SAFS indicator (provided no safety-dropping faults are present).

• GS, DLAB: Door locks. (GSR, DLABR: Rear door logic and door locks.) Connecting 2 bus

to these terminals will cause relay SAFL on the HC-CTL-2 board to pick and light the SAFL

indicator (when direction has been established). The DLK indicator on the HC-MPU board

will turn ON (provided that no safety-dropping faults are present).

• TO2: Thermal overload protection. Connecting TO1 to TO2, as specified on the job prints,

will clear the OLM INPUT IS LOW fault (Overload monitor). When this fault is present the

car can only move down.

If rear doors:

• 2 - GSR

• 2 - DLABR

• 2 - DPMR (Spare input, UIO or CTL-2 - see prints)

To run on Machine Room Inspection:

• Jumper INCT to 2 Bus

HC-CTL-2 Board

HC-DVR Board

FRS

INN

DLAB

GS

FRSA

FRSM

SAFH

SAFC

ESC

GSR

DLABR

2

2

2FS

TO2

UNTD

USL1

USL2

DSL1

DSL2

DNTD

TO1

2L

DPM

Loading...

Loading...