E Series Automated Dispensing System

19www.nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

About Programs and Commands (continued)

Best Practices for Programming

• Insert setup commands (including Acceleration, Dispense Port, and ZClearance) at the beginning of the

program.

• Insert dispense commands after setup commands.

• Insert the End Program command at the end of all programs.

• Name your programs (refer to “How to Name a Program” on page46).

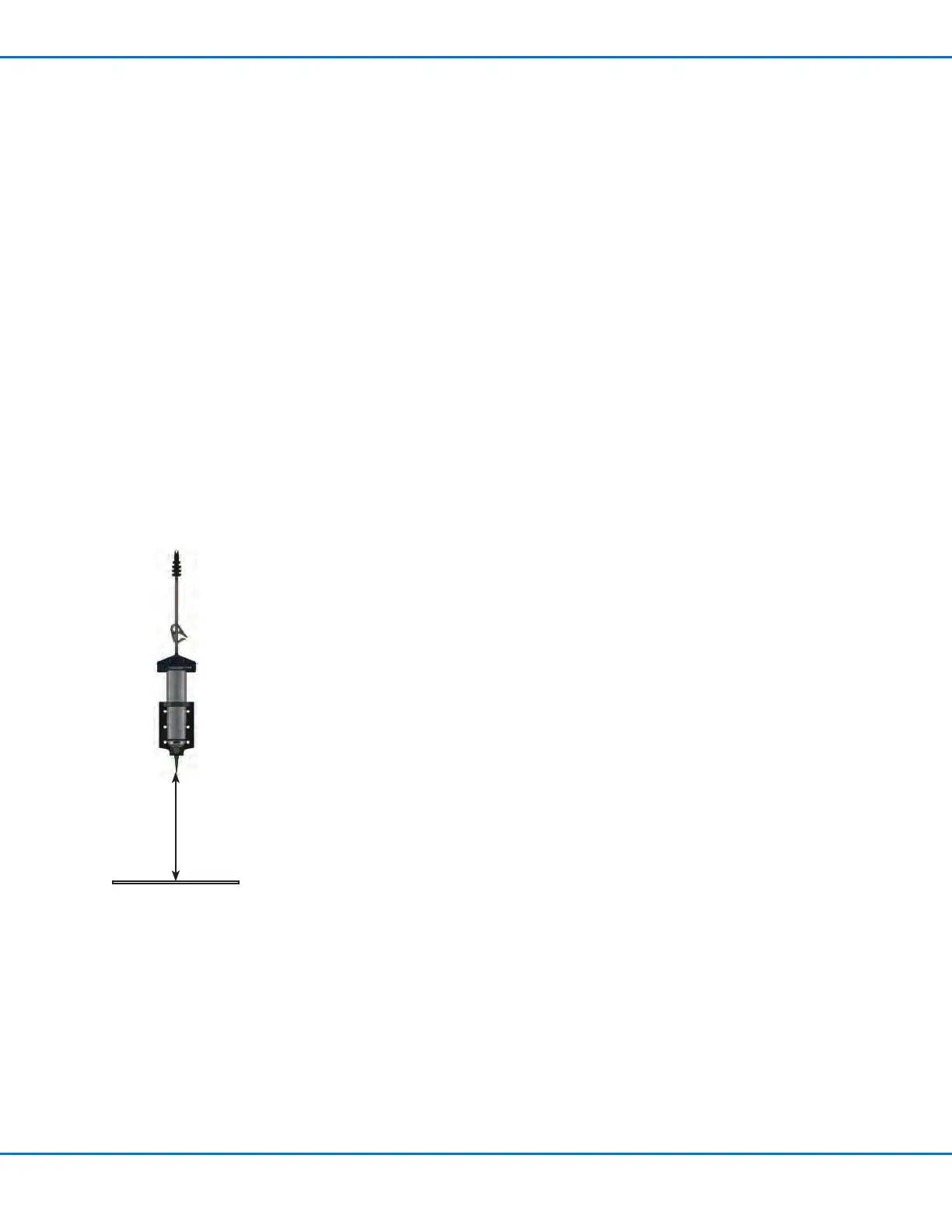

About Tip Height

Tip height is (1) the distance between the bottom of the tip and the workpiece for contact applications or (2) the

distance between the bottom of the nozzle and the workpiece for non-contact applications. The tip height is also

known as the Zclearance.

The tip height must be calibrated and then recalibrated as needed to compensate for slight variations in height that

occur when changes are made to the system, primarily nozzle or tip change-out. If your system includes the optional

tip alignment kit, you can automatically update the tip height at any time using the Auto Needle Adjust feature.

The tip height should be recalibrated as follows:

• At initial startup.

• Any time a component on the Z axis (such as the syringe barrel) is moved.

• Any time a dispensing tip or nozzle is changed.

• Any time the payload or workpiece changes.

About Mark Points

Mark Points are specic points on a workpiece that are set using the Mark Point command. The system uses Mark

Points to adjust all the XY values in a program based on any changes made to the position or orientation of a

workpiece. This adjustment is accomplished through the Program Offset function.

Tip height

(ZClearance)

Workpiece / substrate

Loading...

Loading...