E Series Automated Dispensing System

83www.nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

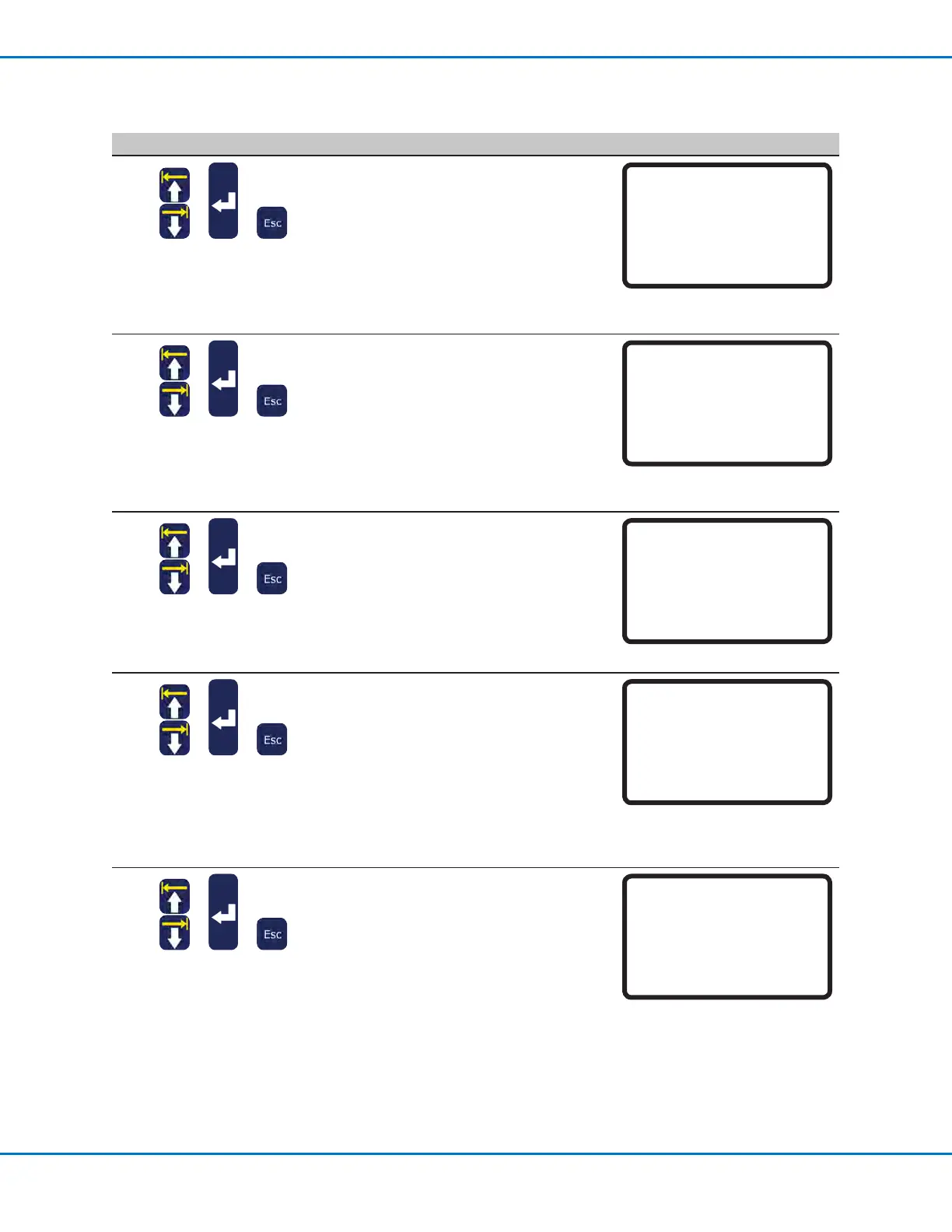

# Key Press Step Teach Pendant Display

4

> >

• Select FRONT PANEL to test the front

panel buttons.

• Press each front panel button one at a

time.

- If a button is functioning properly, the

displayed value for the axis changes

from 0 to 1.

• Press ESC to return to the Diagnostic

menu.

Front Panel

Press front panel buttons

------------------------------

Start Button : 0

Purge Button : 0

Emergency Stop: 0

Needle Sensor : 0

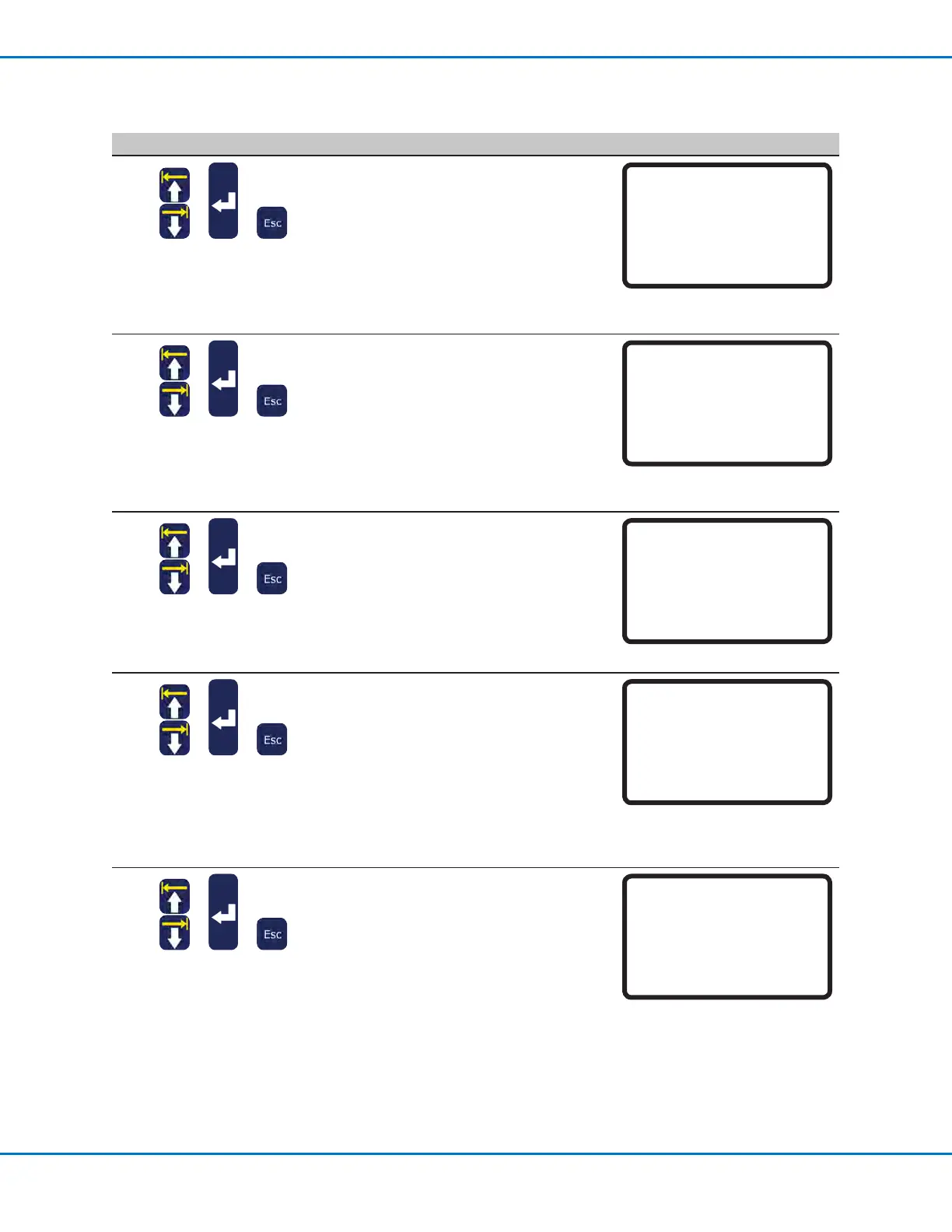

5

> >

• Select INPUT/OUTPUT to test any

connected inputs or outputs.

- If an input / output is functioning

properly, the displayed value for the

input / output changes from 0 to 1.

- Refer to “I/O Port” on page87 for

the IO PORT schematic.

• Press ESC to return to the Diagnostic

menu.

Input/Output

------------------------------

IN : 00000000

OUT: 000000000

Press Key 1-8 Set Output

Press Key 9 Set Dispenser

6

> >

• Select TEACH PAD to test the Teach

Pendant keys.

• Press each TP key one at a time.

- If a key is functioning properly, the

displayed value for SCANCODE

changes from 0 to 1.

• Press ESC to return to the Diagnostic

menu.

Teach Pad

Press key on teach pad

------------------------------

SCANCODE: 0

7

> >

• Select RS232 to test the RS232

connection.

• Connect a DB9 with pins 2 and 3

shorted into the RS232 port on the back

of the robot.

- If the connection is functioning

properly, the system recognizes the

data being sent and received.

• Press ESC to return to the Diagnostic

menu.

RS232

Cross RS232 Pin2 & Pin3

------------------------------

Send Char :00

!!! NO RESPONSE !!!

8

> >

• Select MOTOR to test the robot motor.

• Press the corresponding number key to

test the motor axis.

- If the axis motor is working, a slight

back and forth movement (~10 mm)

of the axis occurs.

• Press and hold ESC until the axis

movement stops and to return to the

Diagnostic menu.

Motor

Axis moves back & forth 10 mm

------------------------------

1 X

2 Y

3 Z

0 Home

Diagnostic Checks (Diagnostic Menu) (continued)

Loading...

Loading...