Parker EME

Specifications

192-120114 N5 C3I22T11 June 2008 401

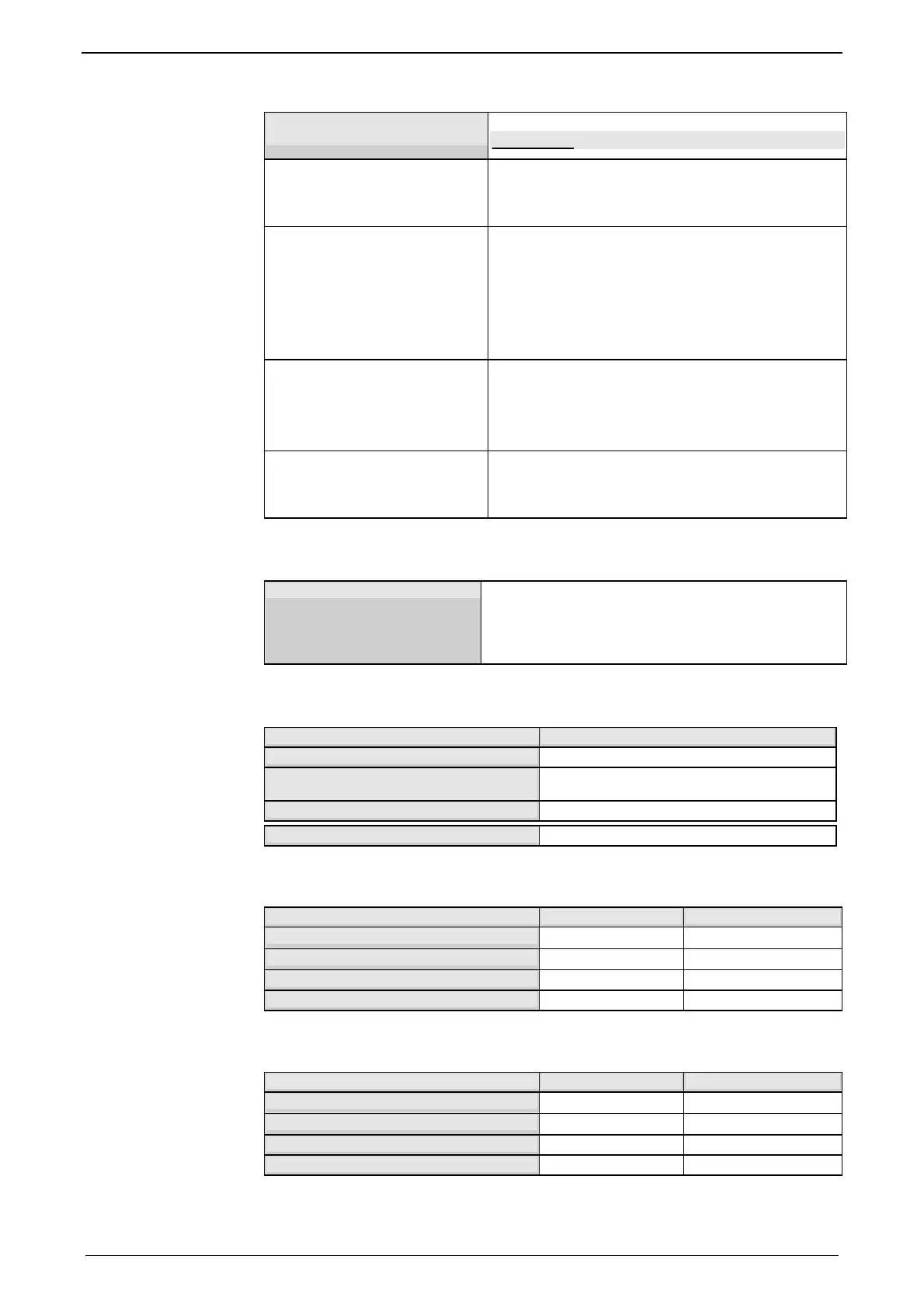

Special encoder systems for

direct drives

Option F12

Analog hall sensors

Sine - cosine signal (max. 5Vss; typical 1Vss)

90° offset

U-V Signal (max. 5Vss; typical 1Vss) 120° offset.

Encoder

(linear or rotatory)

Sine-cosine (max. 5Vss; typical 1Vss) (max.

400kHz) or

TTL (RS422) (max. 5MHz)

with the following modes of commutation:

automatic commutation (see page 347) or

Digital hall sensors (e.g. DiCoder

©

)

Digital, bidirectional interface

All EnDat 2.1 or EnDat 2.2 feedback systems

with incremental track (sine-cosine track)

linear or rotary

max. 400kHz Sine-Cosine

Distance coded feedback sy-

stems

Distance coding with 1VSS - Interface

Distance coding with RS422 - Interface (Enco-

der)

Feedback error compensation

Feedback error compensation

Automatic feedback error compensation (offset &

amplification) for analog hall sensors and sine-

cosine encoder can be activated in the MotorMa-

nager.

Motor holding brake output

Motor holding brake output Compax3

Voltage range

21 – 27VDC

Maximum output current (short circuit

proof)

1.6A

Minimum output current

150 mA

Securing of brake Compax3M

3.15A

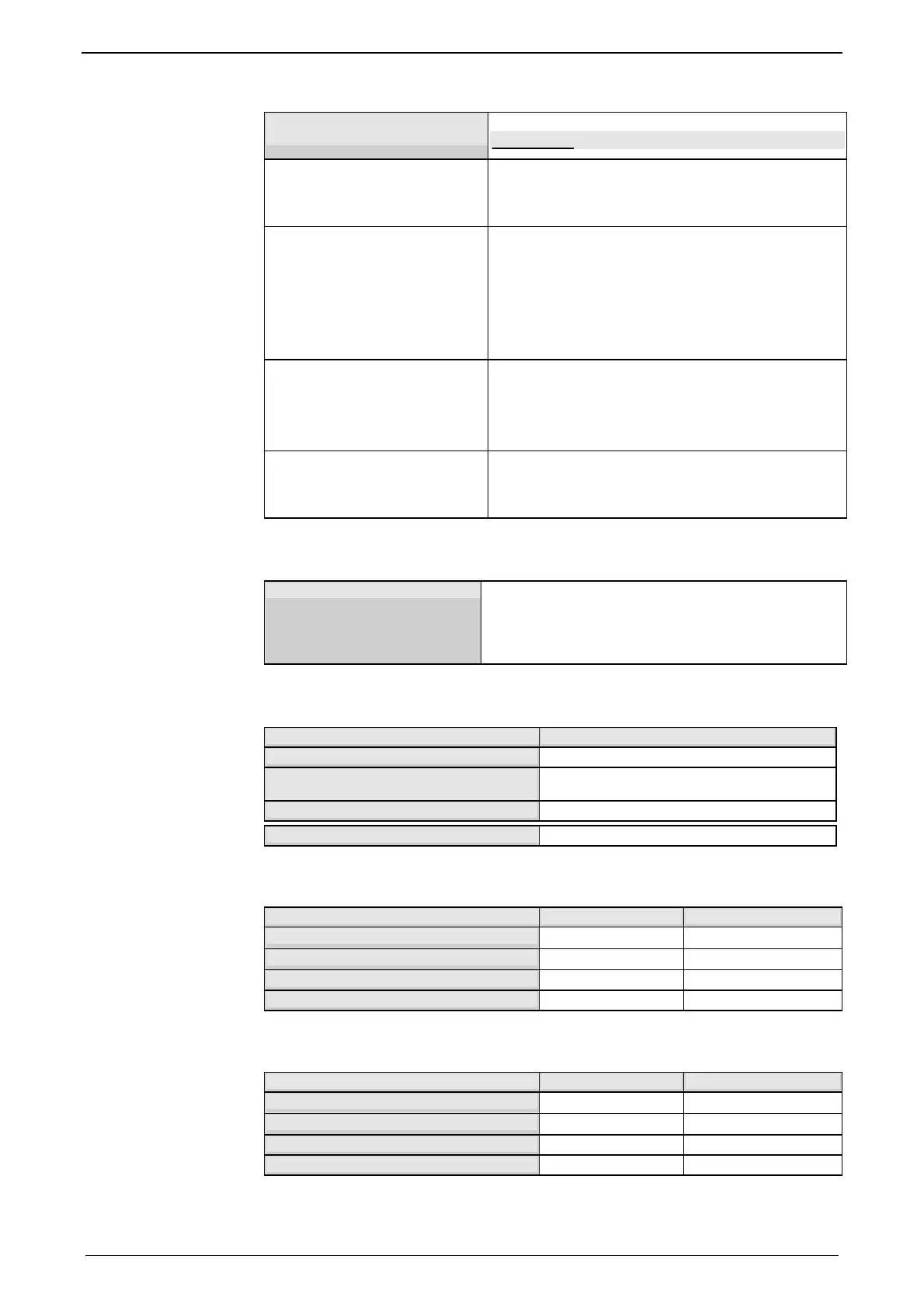

Braking operation Compax3S0xxV2 1AC

Controller type S025V2 S063V2

Capacitance / storable energy

560μF / 15Ws 1120μF / 30Ws

Minimum braking- resistance

100Ω 56Ω

Recommended nominal power rating

20 ... 60W 60 ... 180W

Maximum continuous current

8A 15A

Braking operation Compax3S1xxV2 3AC

Controller type S100V2 S150V2

Capacitance / storable energy

780μF / 21Ws 1170μF / 31Ws

Minimum braking- resistance

22Ω 15Ω

Recommended nominal power rating

60 ... 450W 60 ... 600W

Maximum continuous current

20A 20A

Loading...

Loading...