6.16

9924707 - 2013–2014 RZR 800 Service Manual

© Copyright 2013 Polaris Sales Inc.

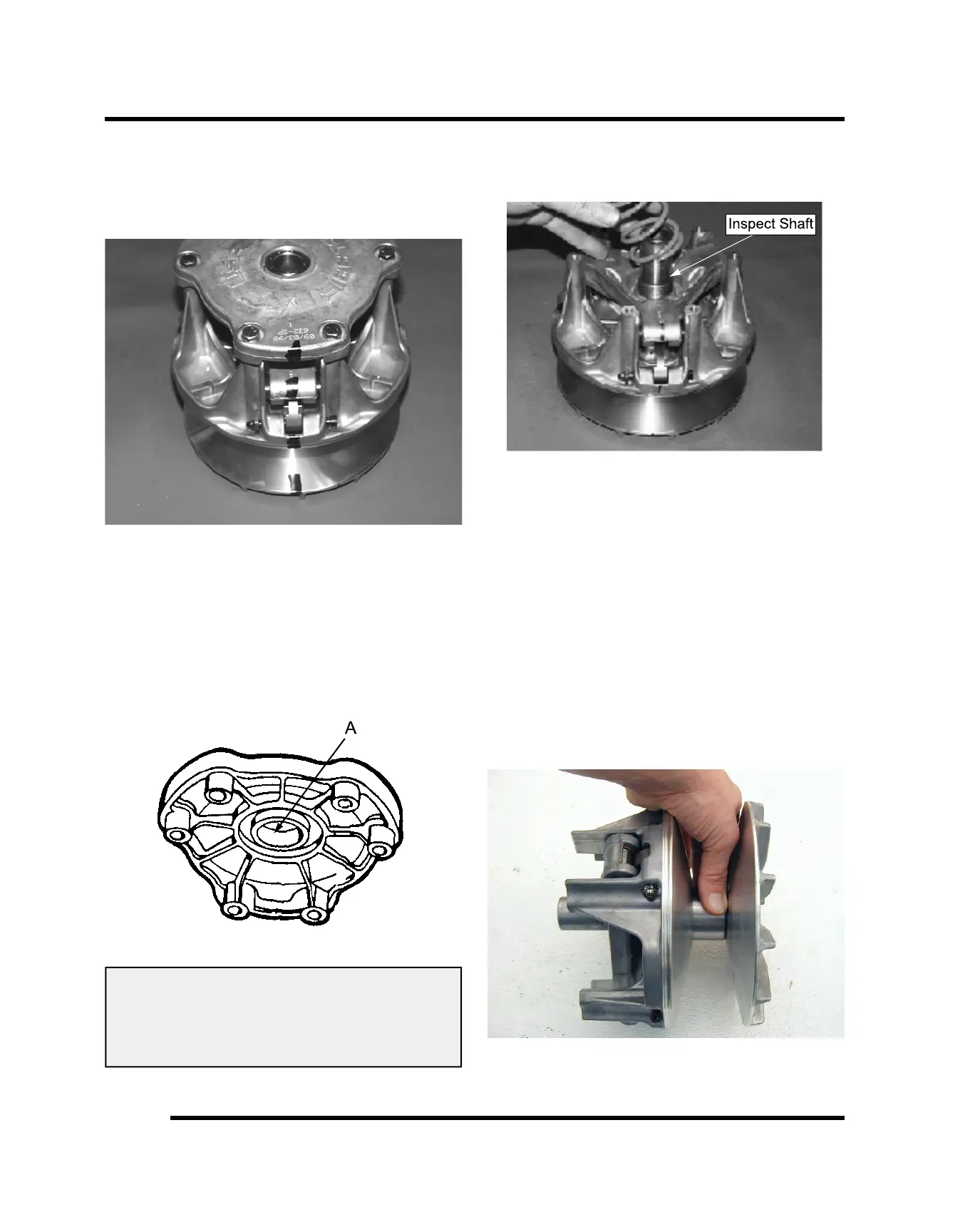

Clutch Disassembly

1. Using a permanent marker, mark the cover, spider,

and moveable and stationary sheaves for reference,

as the cast in X's may not have been in alignment

before disassembly.

2. Mark the stationary sheave and clutch shaft to verify

the shaft has not turned in the sheave after

tightening the spider during clutch assembly.

3. Remove cover bolts evenly in a cross pattern and

remove cover plate.

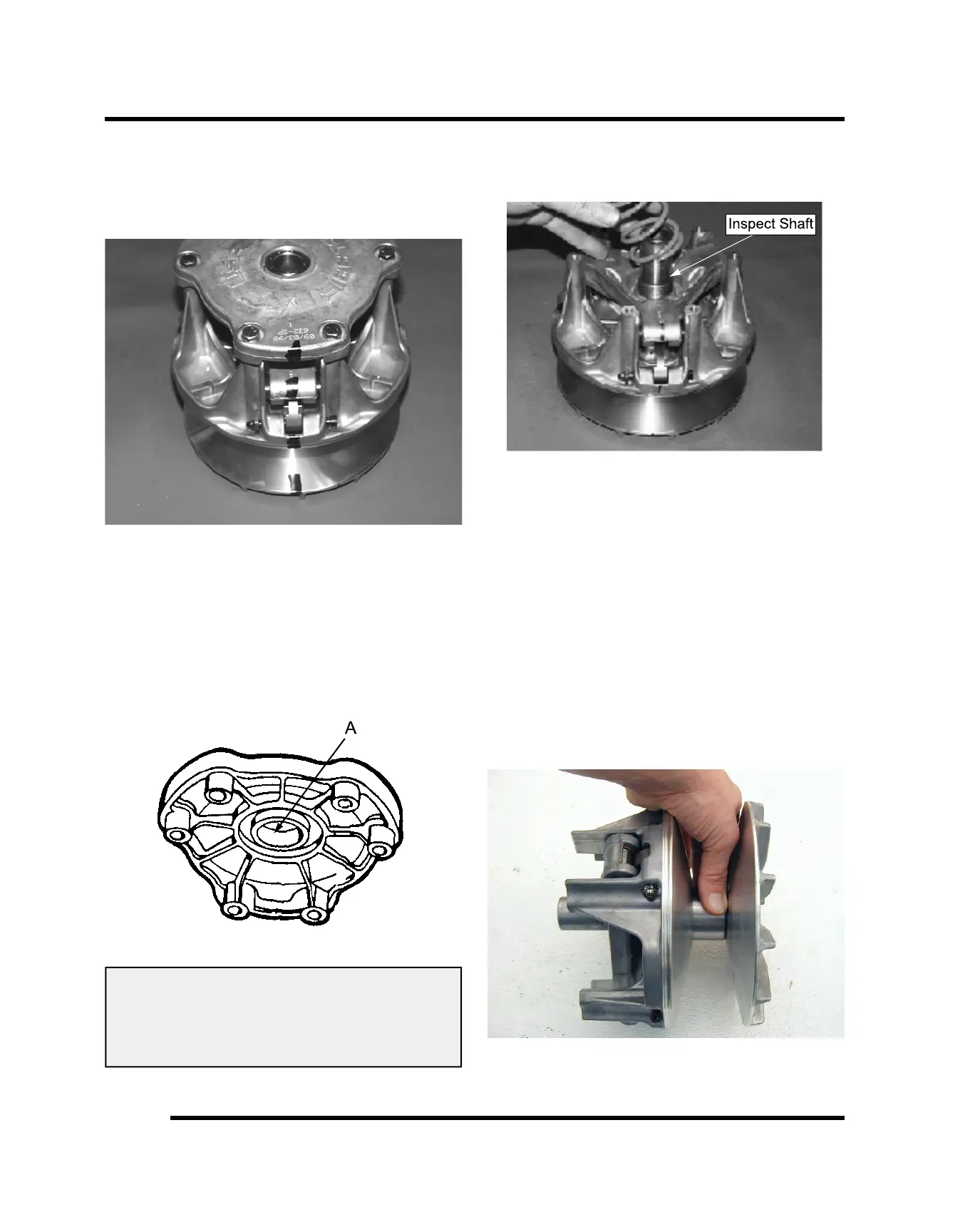

4. Inspect cover bushing (A). The outer cover bushing

is manufactured with a Teflon™ coating. Wear is

determined by the amount of Teflon™ remaining on

the bushing.

Cover Bushing Inspection:

Replace the cover bushing if more

brass than Teflon™ is visible on

the bushing. Refer to bushing

replacement in this chapter.

5. Inspect area on shaft where bushing rides for wear,

galling, nicks, or scratches. Replace clutch assembly

if worn or damaged.

6. Remove and inspect the clutch spring. Refer to

“Drive Clutch Spring Inspection”.

Bearing Inspection

1. Rotate the clutch bearing in both clockwise and

counter-clockwise directions.

• Non-EBS: The non-braking bearing should rotate

both directions on the shaft with only a slight

amount of drag.

• EBS: The one-way bearing should rotate

clockwise (when viewed from cover plate side)

with only a slight amount of drag. When rotated

counter-clockwise the one-way bearing should

lock to the shaft without slipping.

2. Verify there is no binding or rough spots. If problems

are noted continue with disassembly.

CLUTCHING

Loading...

Loading...