Standards Compliance

5

5.3 UL Standards

SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 201

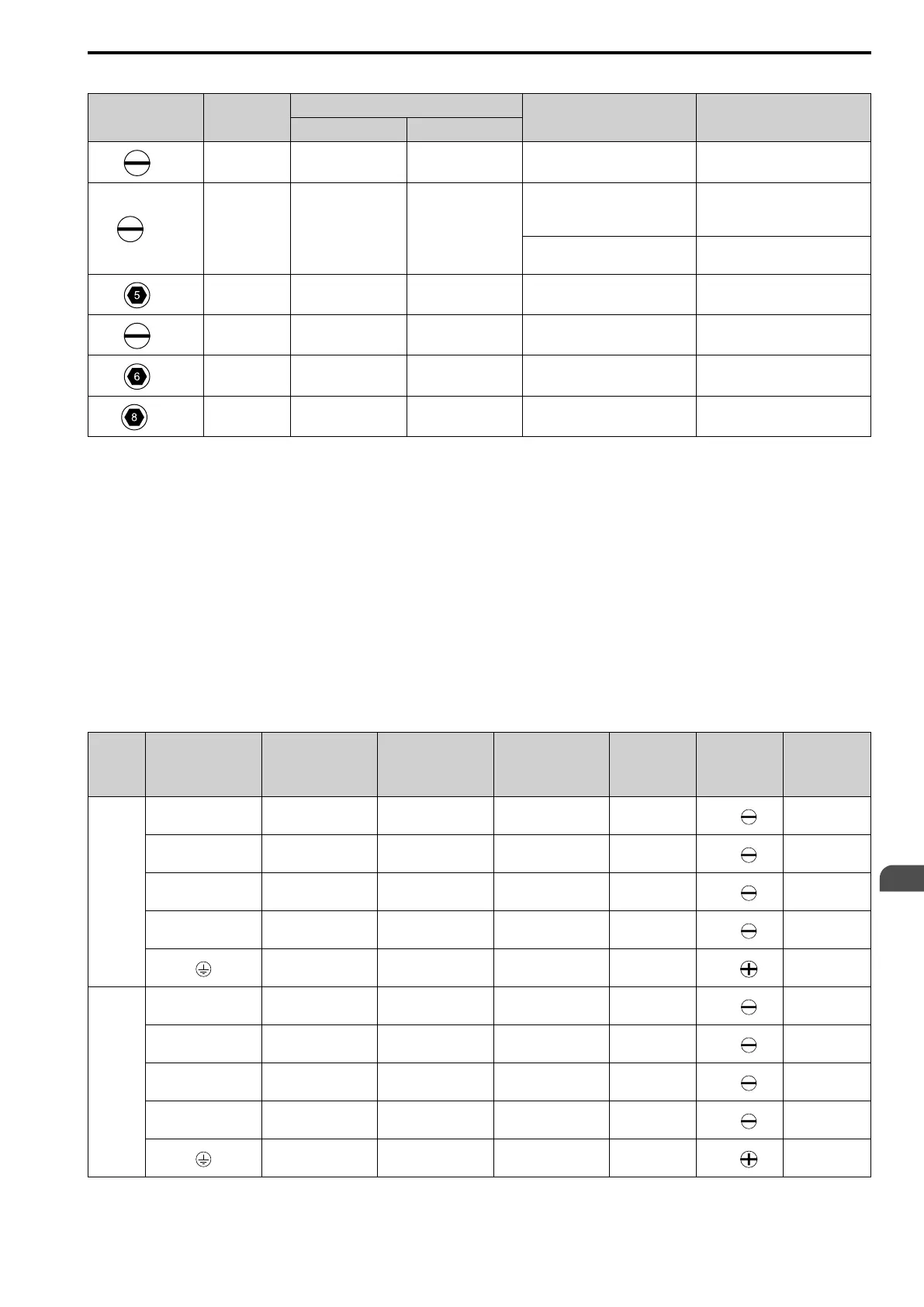

Table 5.10 Recommended Wiring Tools

Screw Adapter

Bit

Torque Driver Model

(Tightening Torque)

Torque Wrench

Model Manufacturer

M4

Bit SF-BIT-SL 1,0X4,0-70 PHOENIX CONTACT

TSD-M 3NM

(1.2 - 3 N∙m)

-

M5

*1

Bit SF-BIT-SL 1,2X6,5-70 PHOENIX CONTACT

Wire Gauge ≤ 25 mm

2

(AWG 10):

TSD-M 3NM

(1.2 - 3 N∙m)

Wire Gauge ≤ 25 mm

2

(AWG 10):

-

Wire Gauge ≥ 30 mm

2

(AWG 8):

-

Wire Gauge ≥ 30 mm

2

(AWG 8):

4.1 - 4.5 N∙m

*2 *3

M6

Bit SF-BIT-HEX 5-50 PHOENIX CONTACT - 5 - 9 N∙m

*2 *3

M6

Bit SF-BIT-SL 1,2X6,5-70 PHOENIX CONTACT - 3 - 3.5 N∙m

*2 *3

M8

Bit SF-BIT-HEX 6-50 PHOENIX CONTACT - 8 - 12 N∙m

*2 *3

M10

Bit SF-BIT-HEX 8-50 PHOENIX CONTACT - 12 - 14 N∙m

*2 *3

*1 When wiring drive models 2056 and 4089 and smaller, select the correct tools for the wire gauge.

*2 Use 6.35 mm (0.25 in) bit socket holder.

*3 Use a torque wrench that can apply this torque measurement range.

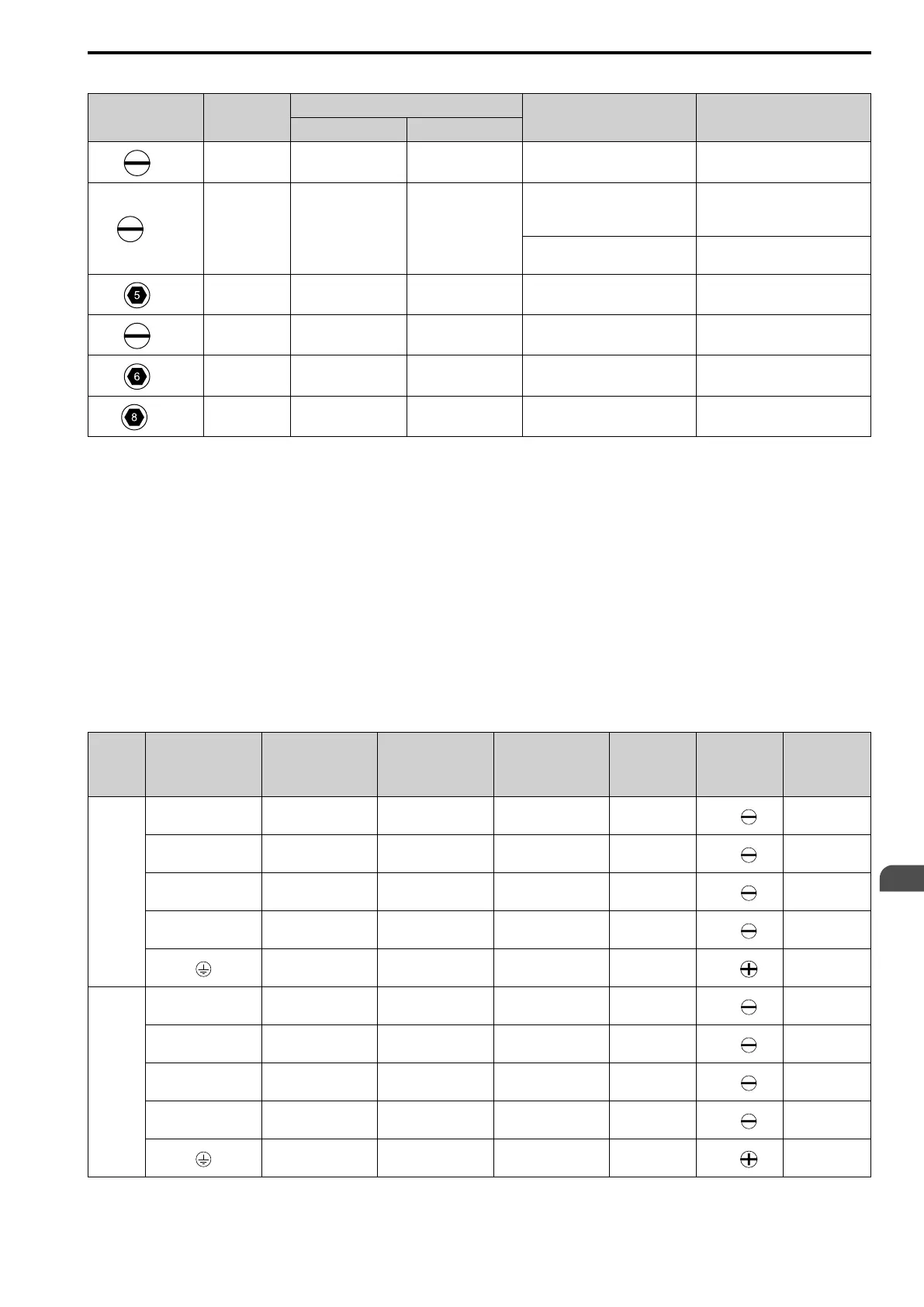

■ Wire Gauges and Tightening Torques as Specified by UL Standards

Comply with local standards for correct wire gauges in the region where the drive is used.

WARNING! Electrical Shock Hazard. Only connect peripheral options, for example a DC reactor or braking resistor, to terminals

+1, +2, +3, -, B1, and B2. Failure to obey can cause death or serious injury.

Refer to Notes on Wire Gauges and Tightening Torques on page 77 for general conditions

Drives from model 2257 and from model 4208, use UL-approved closed-loop crimp terminals on the drive main

circuit terminals. Use the tools recommend by the terminal manufacturer and make sure that the terminals are

correctly connected.

Select the correct wires for main circuit wiring.

Three-Phase 200 V Class

Model Terminal

Recomm. Gauge

AWG, kcmil

Applicable Gauge

AWG, kcmil

(mm

2

)

IP20 Applicable

Gauge

*1

AWG, kcmil

(mm

2

)

Wire Stripping

Length

*2

mm

Terminal Screw

Size and Shape

Tightening

Torque

N∙m (lbf∙in)

2004

R/L1, S/L2, T/L3 14

14 - 6

(2.5 - 16)

14 - 6

(2.5 - 16)

10

M4

1.5 - 1.7

(13.5 - 15)

U/T1, V/T2, W/T3 14

14 - 6

(2.5 - 16)

14 - 6

(2.5 - 16)

10

M4

1.5 - 1.7

(13.5 - 15)

-, +1, +2 14

14 - 3

(2.5 - 25)

14 - 3

(2.5 - 25)

18

M5

2.3 - 2.5

(19.8 - 22)

*3

B1, B2 14

14 - 10

(2.5 - 6.0)

14 - 10

(2.5 - 6.0)

10

M4

1.5 - 1.7

(13.5 - 15)

10

14 - 8

(2.5 - 10)

- -

M4

1.2 - 1.5

(10.6 - 13.3)

2006

R/L1, S/L2, T/L3 14

14 - 6

(2.5 - 16)

14 - 6

(2.5 - 16)

10

M4

1.5 - 1.7

(13.5 - 15)

U/T1, V/T2, W/T3 14

14 - 6

(2.5 - 16)

14 - 6

(2.5 - 16)

10

M4

1.5 - 1.7

(13.5 - 15)

-, +1, +2 14

14 - 3

(2.5 - 25)

14 - 3

(2.5 - 25)

18

M5

2.3 - 2.5

(19.8 - 22)

*3

B1, B2 14

14 - 10

(2.5 - 6.0)

14 - 10

(2.5 - 6.0)

10

M4

1.5 - 1.7

(13.5 - 15)

10

14 - 8

(2.5 - 10)

- -

M4

1.2 - 1.5

(10.6 - 13.3)

Loading...

Loading...