Electrical Installation

3

3.3 Main Circuit Wiring

SIEPYEUOQ2A01G AC Drive Q2A Technical Manual 77

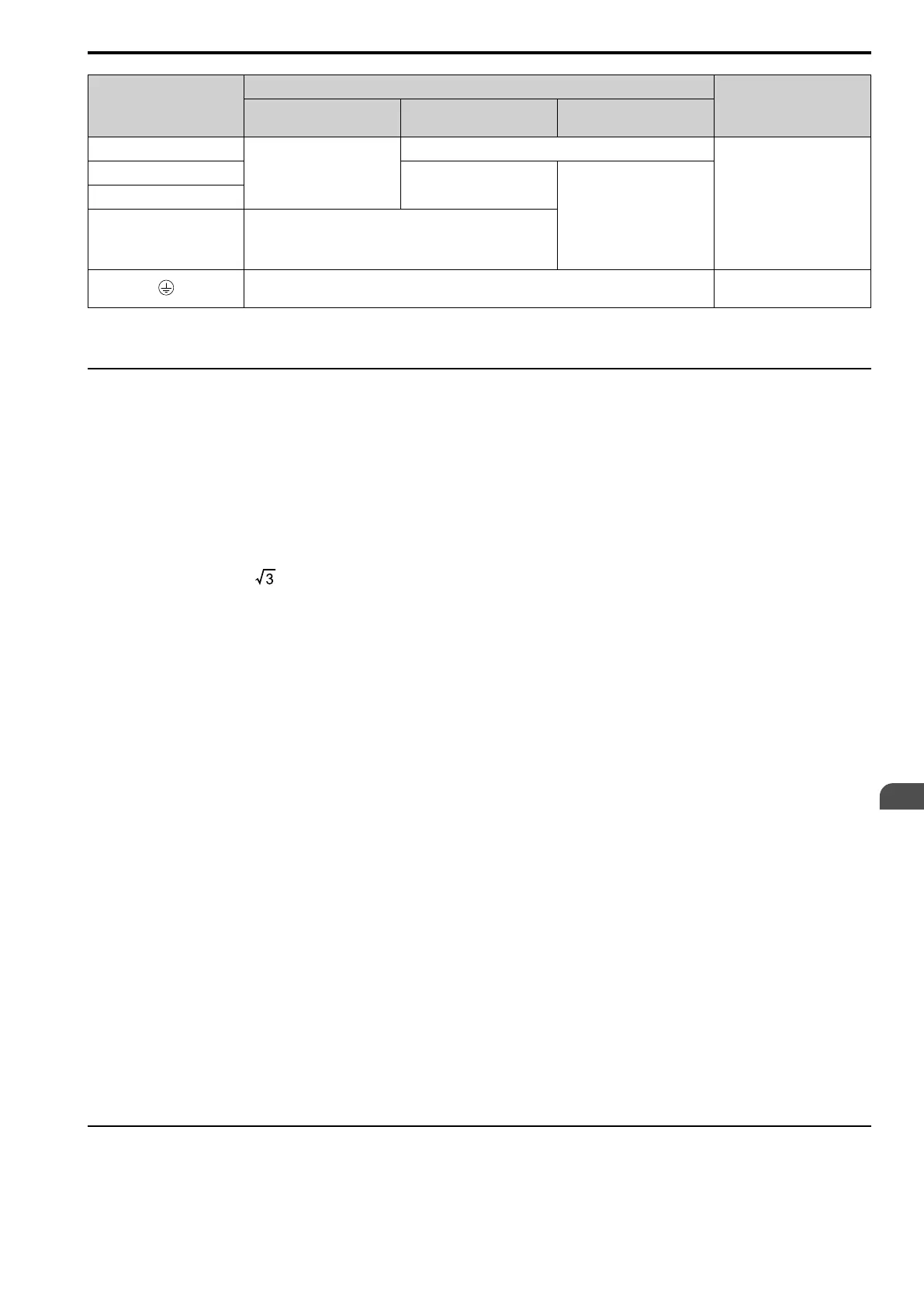

Terminals

Model

Function

2004 - 2082

4002 - 4044

2110 - 2138

4060 - 4168

2169 - 2415

4208 - 4675

+2

• DC power supply input (+1

and -)

• DC reactor connection (+1 and

+2)

-

To connect peripheral devices, for

example:

• DC power input

• Braking Unit

• DC Reactor

Note:

Remove the jumper between

terminals +1 and +2 to

connect a DC reactor.

+1

DC power supply input (+1 and -)

• DC power supply input (+1

and -)

• Braking unit connection (+3

and -)

-

+3 -

• 200 V: D class grounding (ground to 100 Ω or less)

• 400 V: C class grounding (ground to 10 Ω or less)

To ground the drive.

Use terminals B1 and - to connect a CDBR-type control unit to drive models 2004 to 2138 and 4002 to 4168 that

have built-in braking transistors.

◆ Wire Selection

■ Wire Selection Precautions

WARNING! Electrical Shock Hazard. The leakage current of the drive will be more than 3.5 mA. The IEC/EN 61800-5-1: 2007

standard specifies that users must wire the power supply to automatically turn off when the protective ground wire disconnects.

Users can also connect a protective ground wire that has a minimum cross-sectional area of 10 mm

2

(copper wire) or 16 mm

2

(aluminum wire). Failure to obey these standards can cause death or serious injury.

Think about line voltage drop before selecting wire gauges. Select wire gauges that drop the voltage by 2% or less

of the rated voltage. Increase the wire gauge and the cable length when the risk of voltage drops increases.

Calculate line voltage drop with this formula:

Line voltage drop (V) = × wire resistance (Ω/km) × wiring distance (m) × motor rated current (A) × 10

-3

.

■ Precautions during Wiring

• Use terminals B1 and - to connect braking units to drives that have built-in braking transistors (models 2004 to

2138 and 4002 to 4168). Use terminals +3 and - to connect braking units to drives that do not have built-in

braking transistors.

• Refer to “Braking Unit, Braking Resistor Unit Instruction Manual (TOBPC72060001)” for information about

wire gauges and tightening torques to connect braking resistor units or braking units.

• Use terminals +1 and - to connect a regenerative converter or regenerative unit.

NOTICE: Do not connect a braking resistor to terminals +1 or -. Failure to obey can cause damage to the drive circuitry.

■ Notes on Wire Gauges and Tightening Torques

• The recommended wire gauges are based on continuous current ratings of 75 °C (167 °F) 600 V class 2 heat-

resistant indoor PVC wire. Assume these conditions:

– Ambient temperature: 40 °C (104 °F) or lower

– Wiring distance: 100 m (3281 ft.) or shorter

– Normal Duty Rated current value

• Use terminals +1, +2, +3, -, B1, and B2 to connect a peripheral option such as a DC reactor or a braking resistor.

Do not connect other items to these terminals.

• Refer to the instruction manual for each device for recommended wire gauges to connect peripheral devices or

options to terminals +1, +2, +3, -, B1, and B2. Contact the manufacturer or your nearest sales representative if

the recommended wire gauges for the peripheral devices or options are out of the range of the applicable gauges

for the drive.

Select the correct wires for main circuit wiring.

Refer to Wire Gauges and Tightening Torques as Specified by European Standards on page 178.

Refer to Wire Gauges and Tightening Torques as Specified by UL Standards on page 201.

◆ Main Circuit Terminal and Motor Wiring

This section outlines the various steps, precautions, and checkpoints for wiring the main circuit terminals and

motor terminals.

Loading...

Loading...