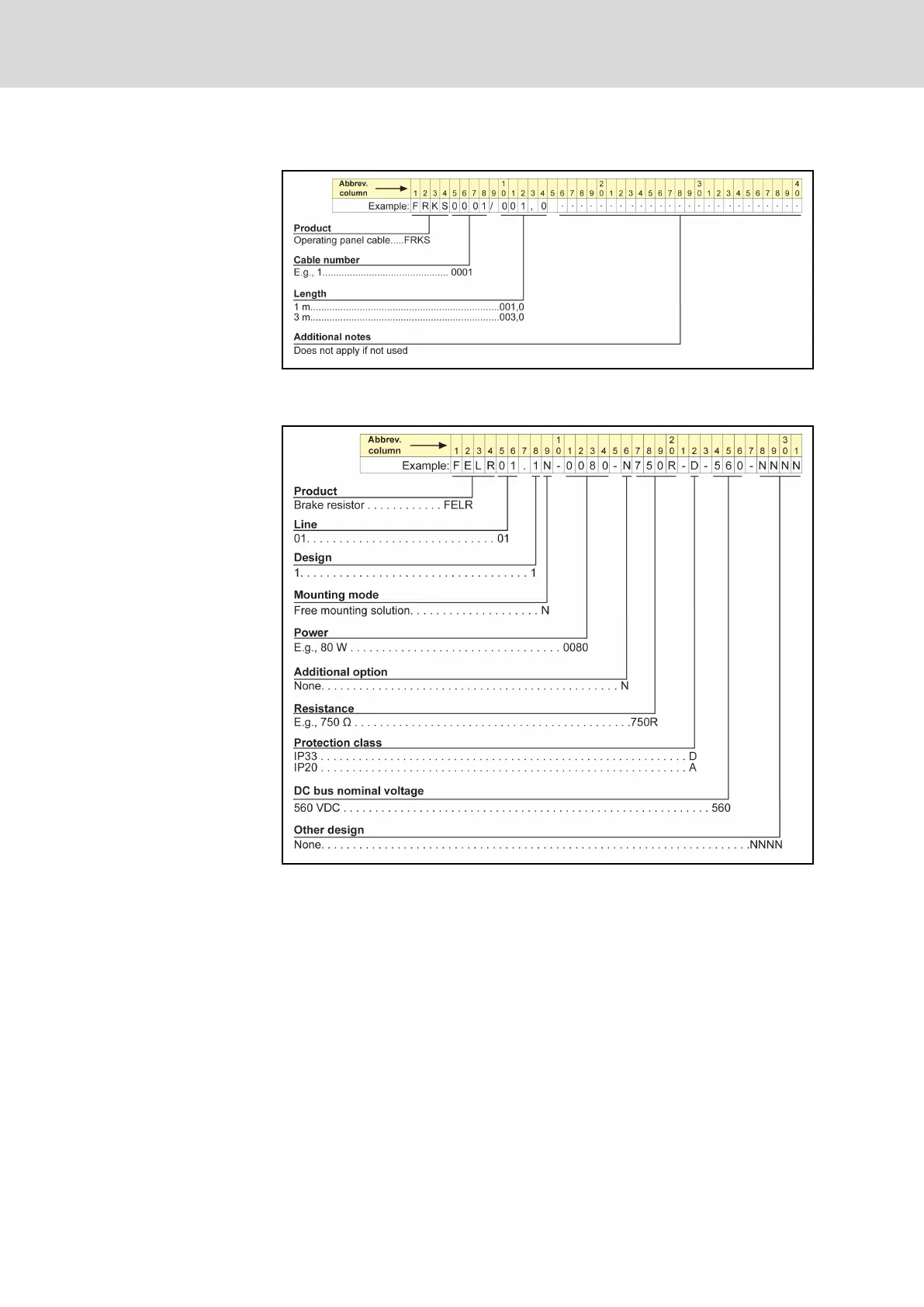

Operating panel cable type coding

Fig. 1-7: Operating panel cable type coding

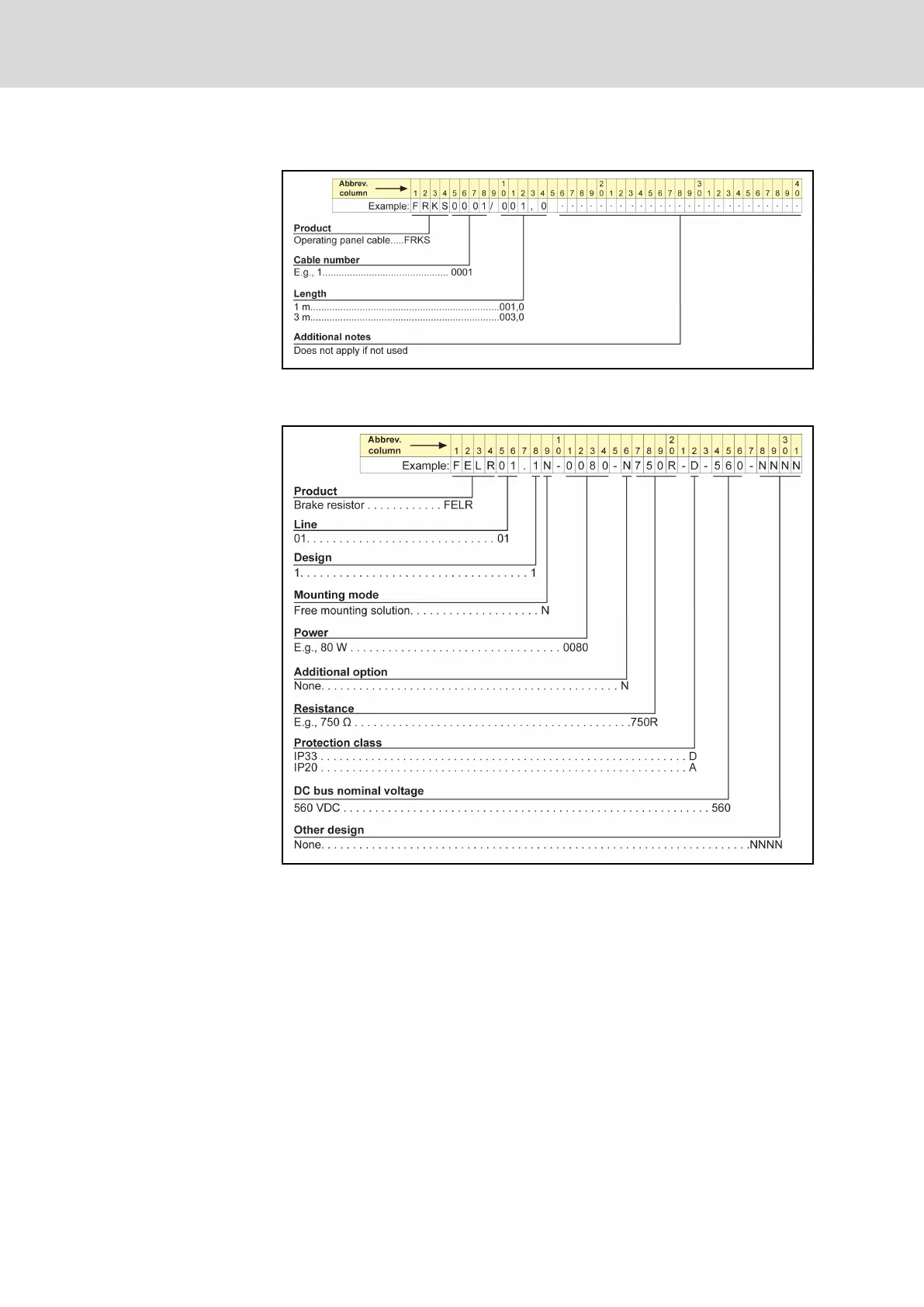

Brake resistor type coding

Fig. 1-8: Brake resistor type coding

Bosch Rexroth AG DOK-RCON02-FV*********-IB08-EN-P16/259

Rexroth Frequency Converter Fv

Introduction

Loading...

Loading...