Section 02 ENGINE

Subsection 07 (PTO HOUSING AND MAGNETO)

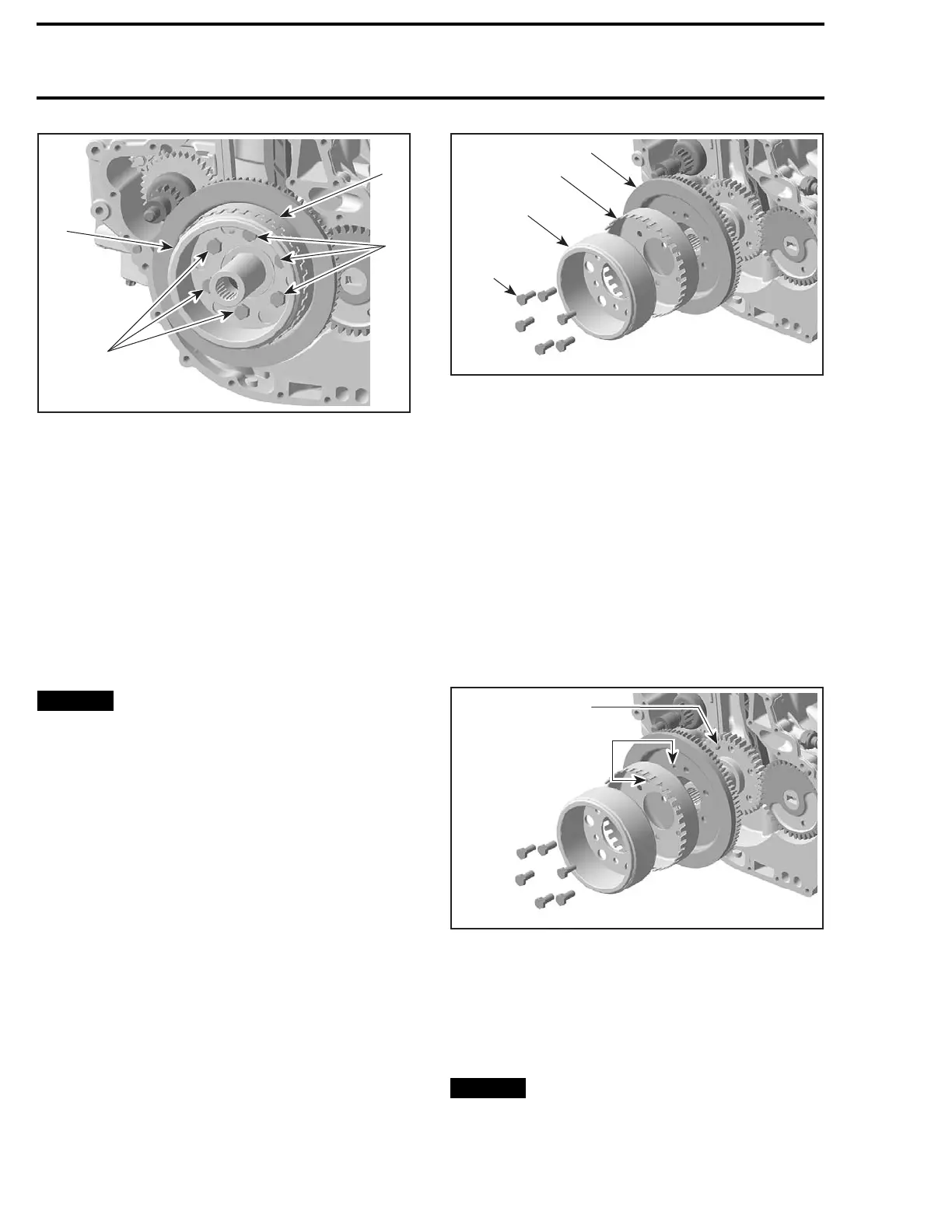

1

R1503motr53A

2

3

1

TYPICAL

1. Rotor retaining screws

2. Rotor

3. Trigger wheel

Rotor and Trigger Wheel Installation

For installation, reverse the removal procedure.

However, pay attention to the following.

Align the trigger wheel to the crankshaft using the

location pin on the crankshaft end.

Install NEW OEM rotor screws and torque them

to 15 N•m (133 lbf•in) using a crisscross pattern.

Finish tightening screws with an additional 50° ro-

tation with a torque angle gauge.

NOTICE

Always install NEW OEM screws

with pre-applied threadlocker. These are

stretch screws that are one time use only.

Not replacing rotor screws may lead to engine

damage and failure.

RING GEAR

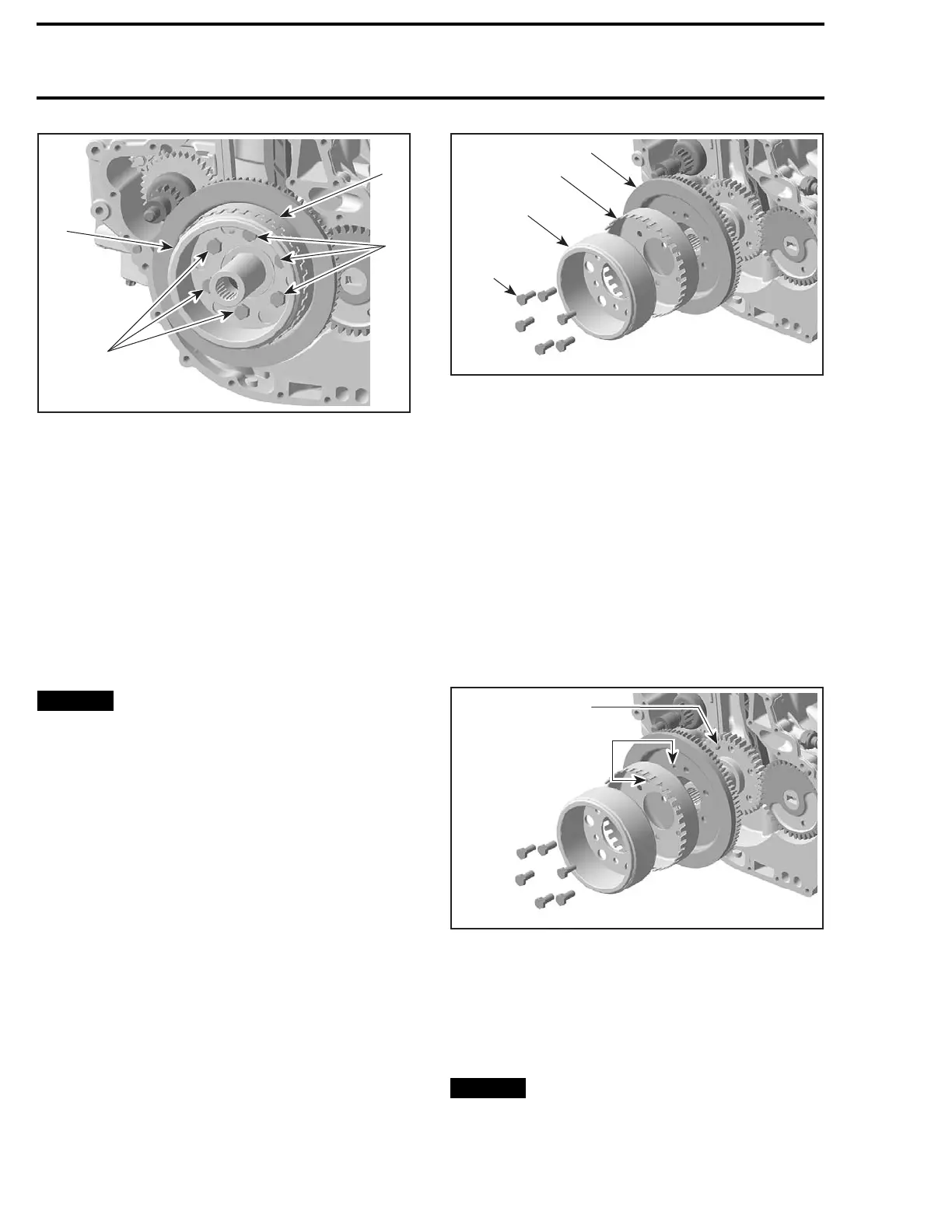

Ring Gear Removal

Lock crankshaft. Refer to

CYLINDER BLOCK

sub-

section for procedure.

Remove the PTO housing cover, see procedure in

this subsection.

Remove and discard the magneto rotor retaining

screws.

Pull rotor and trigger wheel off crankshaft end.

Pull rotor, trigger wheel, and ring gear off crank-

shaft end.

1

R1503motr54A

2

3

4

TYPICAL

1. Magneto rotor retaining screws

2. Rotor

3. Trigger wheel

4. Ring gear

Ring Gear Inspection

Inspect ring gear for damages. Pay particular at-

tention to teeth condition. If badly worn, cracked,

or broken teeth are found, replace ring gear.

Ring Gear Installation

For installation, reverse the removal procedure.

However, pay attention to the following.

Align the ring gear and trigger wheel to the crank-

shaft using the location pin on the crankshaft end.

1

R1503motr54B

2

TYPICA

L

1. Location pin

2. Location pin holes

Instal

l NEW OEM rotor screws and torque them

to 15 N

•m (133 lbf•in) in a crisscross pattern.

Finish tightening screws with an additional 50° ro-

tation with a torque angle gauge.

NOTICE

Alway

s install NEW OEM screws

with p

re-applied threadlocker. These are

stret

ch screws that are one time use only.

Not re

placing rotor screws may lead to engine

damag

e and failure.

82 smr2009-022

Loading...

Loading...