Section 02 ENGINE

Subsection 09 (COOLING SYSTEM)

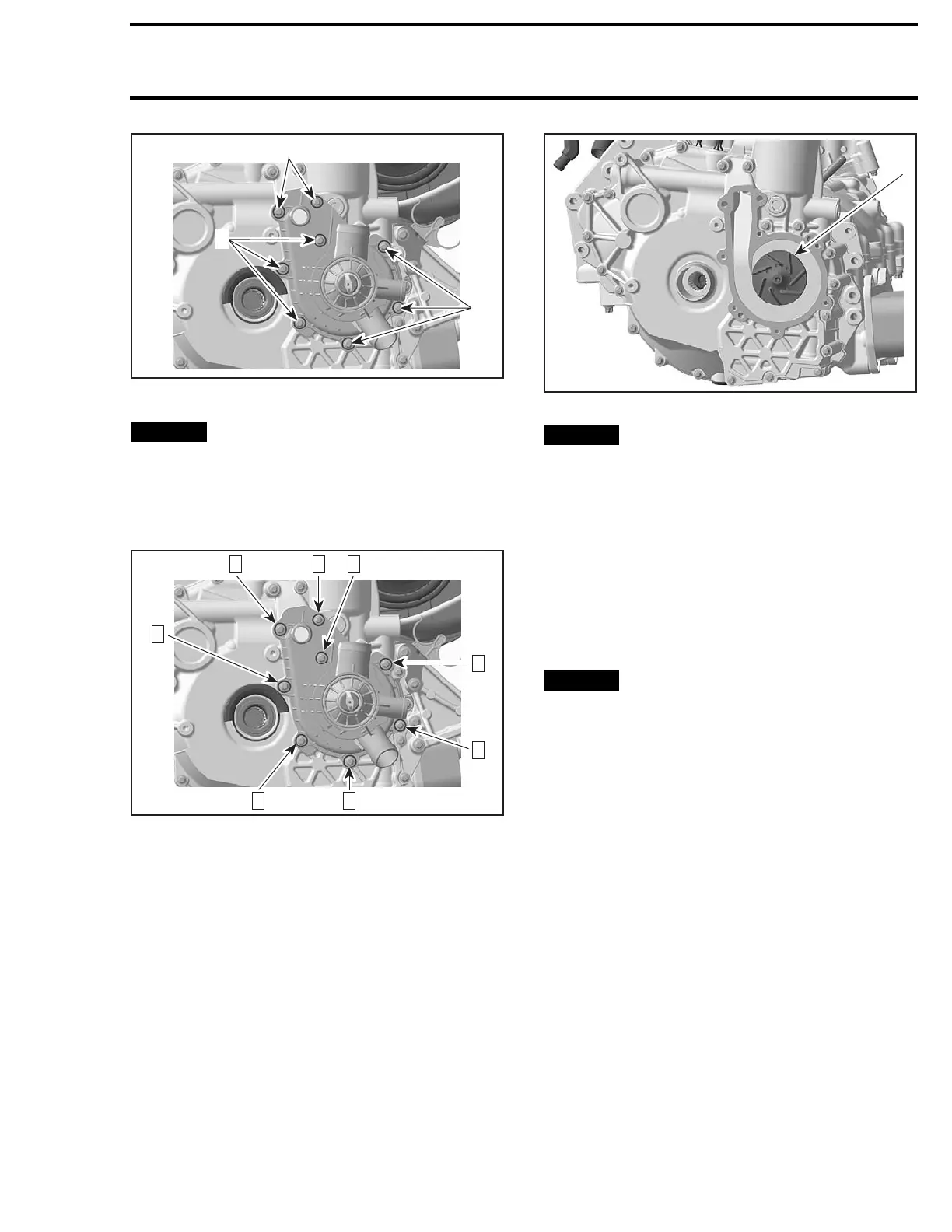

F18E10A

2

1

1

1. Screws M6 x 25

2. Screws M6 x 105

NOTICE

To prevent leaking, take care that the

gaskets are exactly in groove when you rein-

stall the water pump housing.

Tighten screws to 9 N•m (80 lbf•in) using the fol-

lowing sequence.

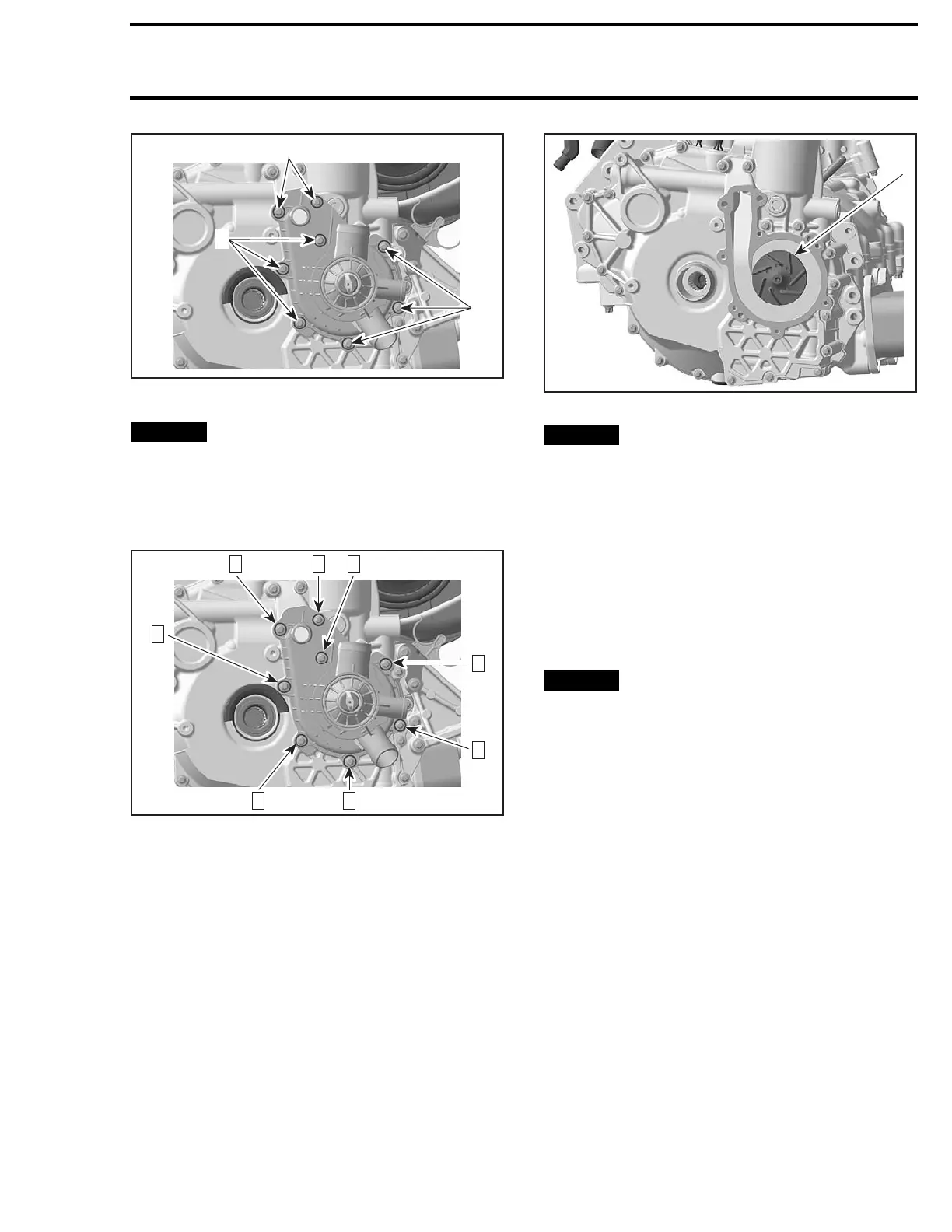

F18E10B

32

4

5

1887

6

WATER

PUMP IMPELLER

Water Pump Impeller Removal

Remov

ethe

WATER PUMP HOUSING

, see pro-

cedur

e in this subsection.

Unscrew the impeller clockwise.

1

F18E13A

1. Impeller

NOTICE

Coolant/oil pump shaft and impeller

have left-hand threads. Remove by turning

clockwise and install by turning counterclock-

wise.

WaterPumpImpellerInspection

Check impeller for cracks or other damage. Re-

place impeller if damaged.

Water Pump Impeller Installation

The installation is the opposite of the removal pro-

cedure. Pay attention to the following details.

NOTICE

Be careful not to damage impeller

wings during installation.

Torque impeller to 3 N•m (27 lbf•in).

THERMOSTAT

The thermostat is a single action type.

Thermostat Removal

Remove the

WATER PUMP HOUSING

, see pro-

cedure in this subsection.

NOTE: The thermostat is located inside the water

pump housing.

Thermostat Test

To check the operation of the thermostat, put it in

water and heat water.

Look inside the cylinder head return hose con-

nection to see the movement of the thermostat.

Thermostat should open when water tempera-

ture reaches 87°C (189°F).

If there is no operation, replace the water pump

housing.

smr2009-024 123

Loading...

Loading...