Section 02 ENGINE

Subsection 11 (CYLINDER BLOCK)

GENERAL

When disassembling parts that are duplicated in

the engine, (e.g.: pistons, connecting rods etc.),

it is strongly recommended to note their position

(cylinder 1, 2 or 3) and to keep them as a “group”.

If you find a defective component, it would be

much easier to find the cause of the failure within

the group of parts. Besides, since used parts

have matched together during the engine oper-

ation, they will keep their matched fit when you

reassemble them together within their “group”.

During asse

mbly/installation, use torque values

and service

products as in the exploded view.

Clean threads before applying a threadlocker. Re-

fer to

SELF-LOCKING FASTENERS

and

LOCTITE

APPLICATION

at the beginning of this manual for

complete procedure.

WARNING

Torque wre

nch tightening specifications

must be str

ictly adhered to.

Locking de

vices (e.g.: locking tabs, elastic

stop nuts

, self-locking fasteners, cotter pins,

etc.) mus

t be replaced with new ones.

Hoses, cables or locking ties removed during a

procedure must be reinstalled as per factory stan-

dards.

TROUBLESHOOTING

The following is provided to help in diagnosing the

probable source of troubles. It is a guideline and

it should not be assumed to list all possible prob-

lems.

Always check for fault codes. If a fault code is de-

tected, service the fault code first. Refer to

EN-

GINE MANAGEMENT

section.

UNUSUAL ENGINE NOISE OR

VIBRATIONS

1. Heavy wear on plain bearings

- Check radial play of plain bearings.

- Replace plain bearings if out of specification.

2. Crankshaft and balancer shaft are not properly

aligned

- Disassemble cylinder block and check if marks

are properly aligned.

3. Crankshaft or balancer shaft axial play out of

specification

- Measure crankshaft and balancer shaft axial play.

- If axial play is out of specification, replace thrust

washers.

4. Connecting rod axial play out of specification

- Measure connecting rod axial play on crankshaft.

- Replace connecting rod or crankshaft if out of

specification.

5. Connecting rod screws got loose

- Replace damaged components and retighten

screws with the recommended torque.

BLUE SMOKE IN THE EXHAUST

1. Oil scrapper rings worn out

- Replace piston rings.

ENGINE SUDDENLY TURNS OFF (POOR

IDLING)

1. Piston rings worn out

- Replace piston rings.

2. Piston/cylinder wall clearance out of specifica-

tion

- Check piston/cylinder wall clearance.

- Replace if out of specification.

3. Melted or broken piston

- Check if oil spray nozzle is not clogged. Refer to

LUBRICATION SYSTEM subsection.

- Replace piston and cylinder block if necessary.

PROCEDURES

TIMING CHAIN

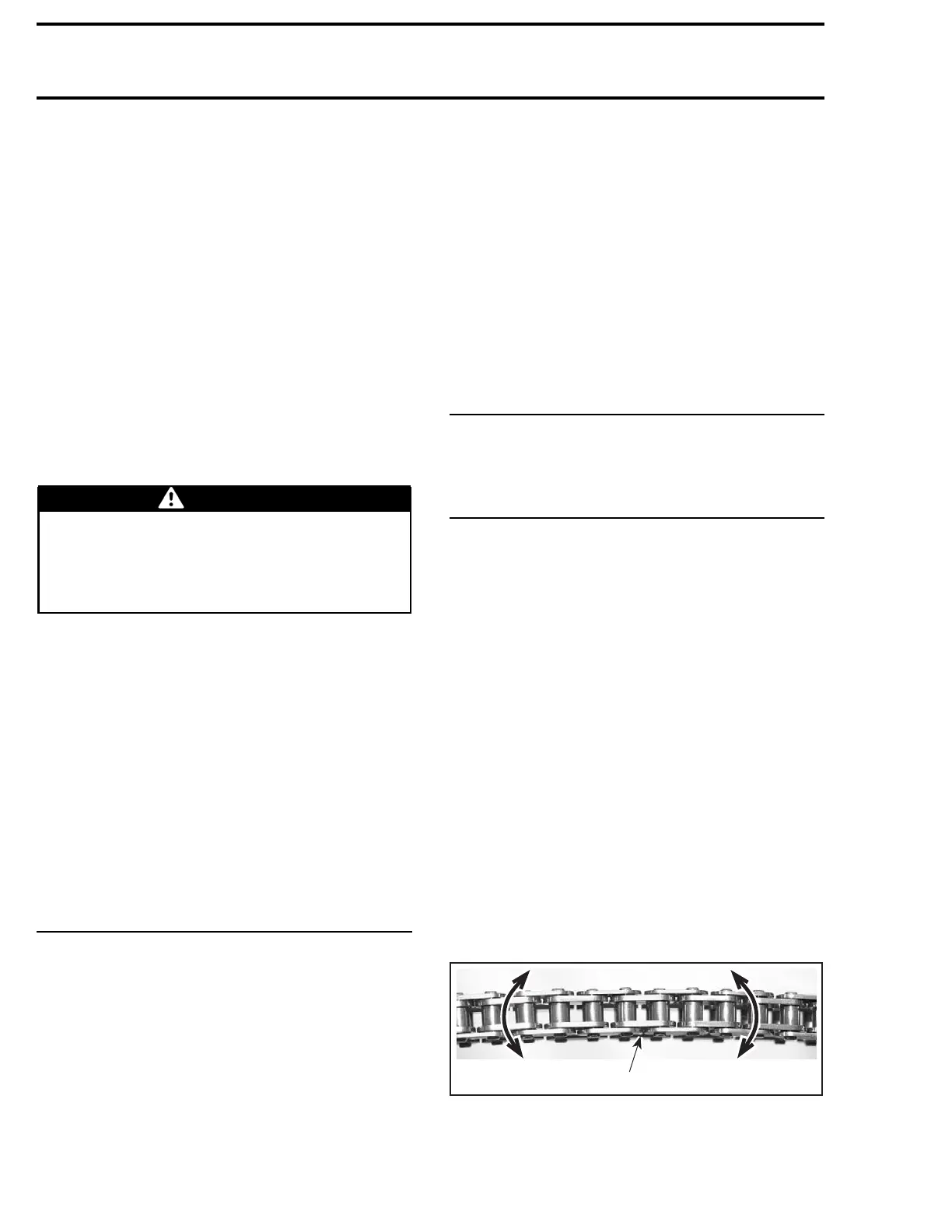

Timing Chain Inspection

Check timing chain on camshaft gear for exces-

sive radial play.

Check chain condition for wear and rollers condi-

tion.

1

R610motr201A

1. Timi

ng chain

If chain is excessively worn or damaged, replace

it as a set (camshaft timing gear and timing chain).

152 smr2009-026

Loading...

Loading...