Section 02 ENGINE

Subsection 10 (CYLINDER HEAD)

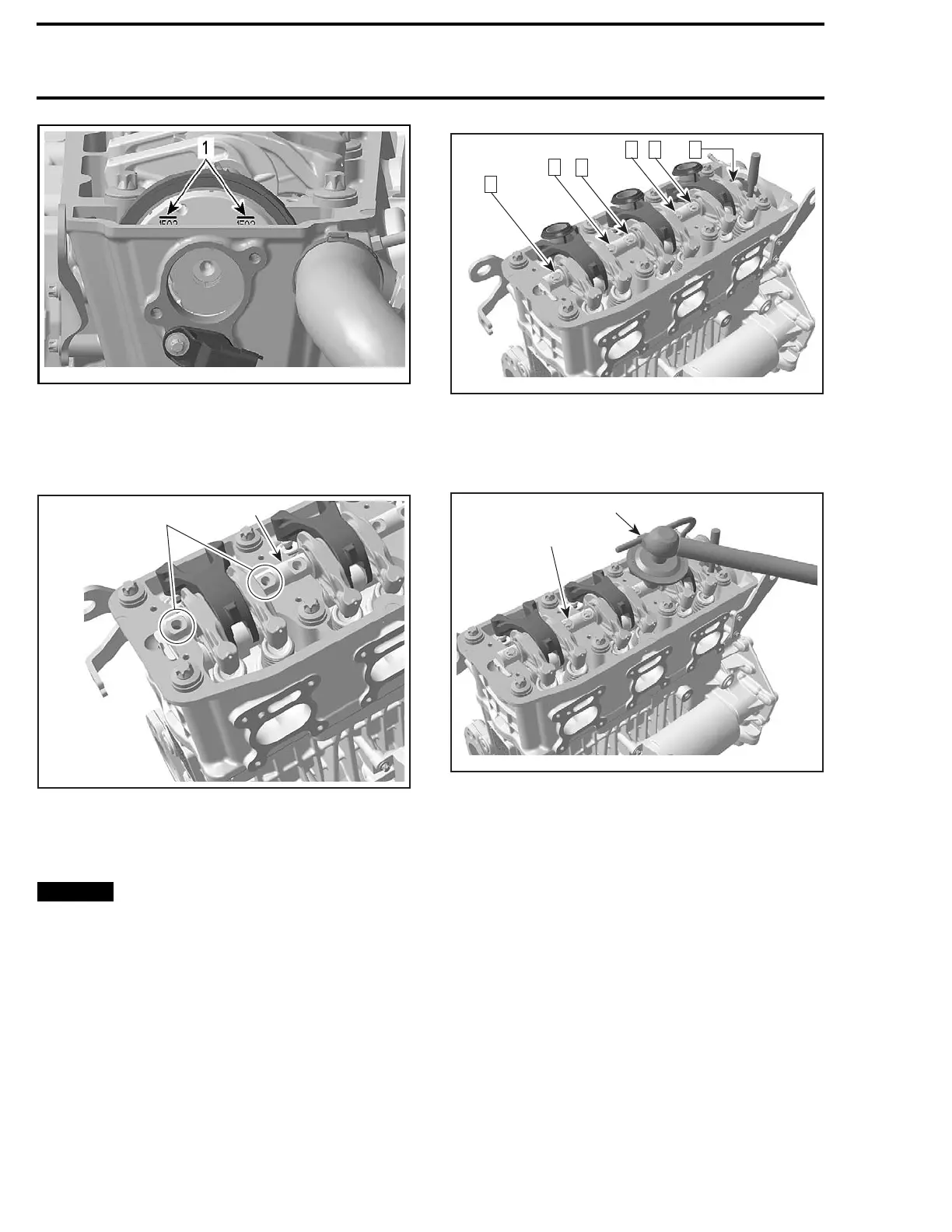

smr2009-025-006_a

1. Position lines

3. Apply engine oil on rocker arm shaft.

4. Position the rocker arm shaft with the notches

on top.

1

R1503motr91A

2

1. Rocker arm shaft

2. Rocker arm shaft notches

5. Inst

all NEW rocker arm shaft screws. Torque as

per f

ollowing procedure:

NOTICE

This assembly uses stretch screws.

As the screws have been stretched from the

previous installation, it is very important to

use new screws at assembly. Failure to re-

place screws and to strictly follow the torque

procedure may cause screws to loosen and

lead to engine damage.

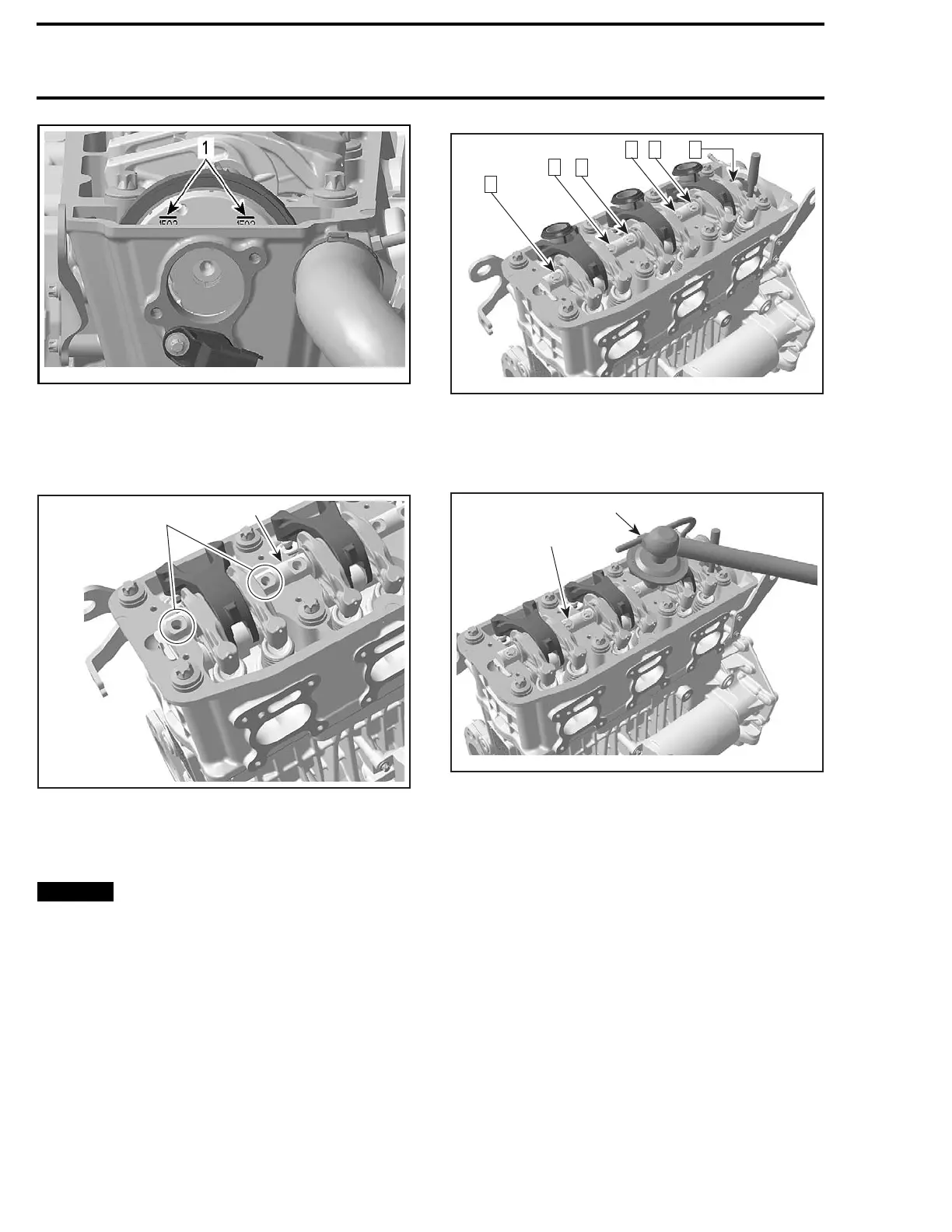

6. Torque screws at first to 10 N•m (89 lbf•in) ac-

cording to following sequence.

R1503motr93A

2

1 3 4

5

6

7. Retorque screws to 20 N•m (15 lbf•ft).

8. Finish tightening screws turning an additional

90° rotation with a torque angle gauge.

1

R1503motr92A

2

1. Rocker arm shaft screw

2. Torqu

e angle gauge

CAMSH

AFT TIMING GEAR

NOTE: Although it is not necessary to position

crankshaft to TDC for disassembly, it is a good

practice to do it, as a troubleshooting step, to

know before disassembly if valve timing was

appropriate.

Cams

haft Timing Gear Removal

Lock crankshaft, refer to

CYLINDER BLOCK

sub-

section.

Remove

CYLINDER HEAD COVER

, see proce-

dure above in this subsection.

Lock

camshaft. Refer to

CAMSHAFT

in this sub-

sect

ion.

Remove the oil separator cover. Refer to

LUBRI-

CATION SYSTEM

subsection.

136 smr2009-025

Loading...

Loading...