Section 02 ENGINE

Subsection 11 (CYLINDER BLOCK)

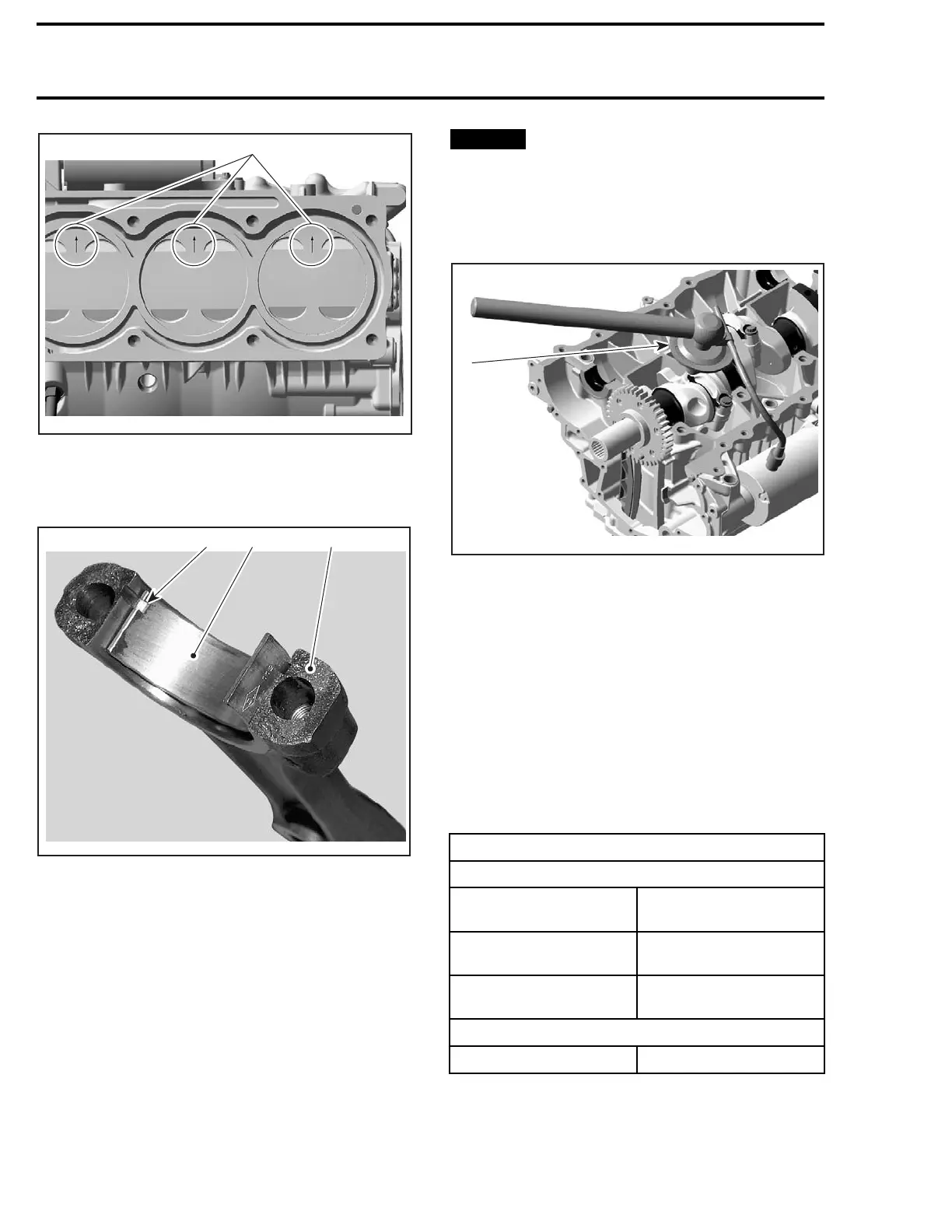

1

R1503motr30A

1. Arrow toward exhaust side

2. Correctly install bearings and carefully clean

split surface on both sides (cracked area).

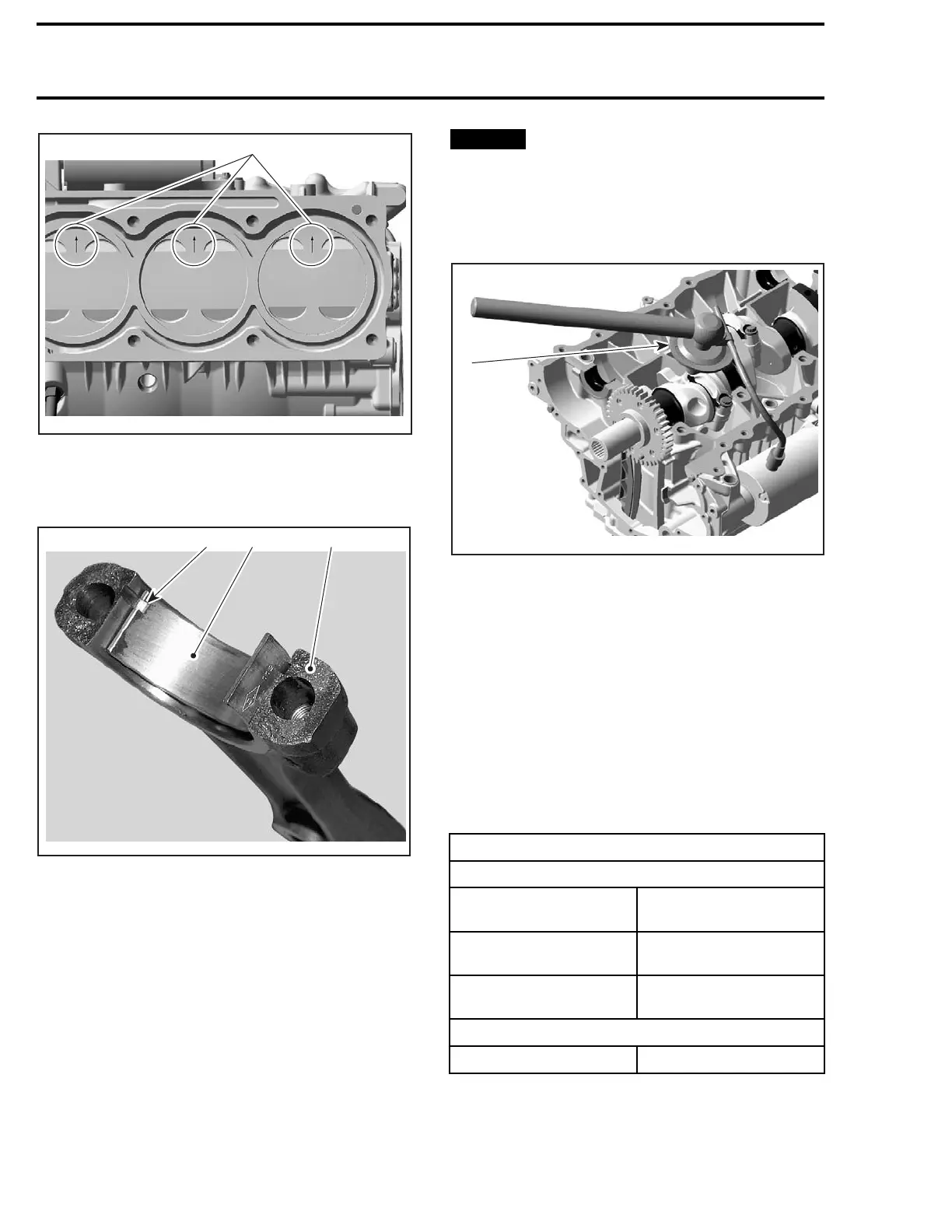

3

R610motr79A

12

1. Half bearing of connecting rod big end

2. Spli

t surface of the connecting rod

3. Protrusion of bearing in line with connecting rod groove

3. Torque NEW connecting rod screws no. 11 as

per following procedure:

3.1 Install screws and torque to 45 N•m

(33 lbf•ft). Do not apply any threadlocker

product.

3.2 Fin

ish tightening the screws with an ad-

di

tional 90° turn using an angle torque

wr

ench.

NOTICE

Failure to strictly follow this proce-

dure may cause screw to loosen and lead to

engine damage. Knowing that the screws have

been stretched from the previous installation,

it is very important to use new screws at as-

sembly.

R1503motr31A

1

1. Angle to

rque wrench

PISTON R

INGS

Piston Ring Removal

Remove p

iston as described above.

Remove rings.

Piston R

ing Inspection

Ring/Piston Groove Clearance

Using a feeler gauge measure each ring/piston

groove clearance. If the clearance is too large, the

piston and the piston rings should be replaced.

RING/PISTON GROOVE CLEARANCE

NEW

RECTANGULAR

0.025 mm - 0.070 mm

(.001in - .0028 in)

TAPER-FACE

0.015 mm - 0.060 mm

(.0006 in - .0024 in)

OIL SCRAPER RING

0.020 mm - 0.055 mm

(.0008 in - .0022 in)

SERVI

CE LIMIT

ALL

0.15 mm (.006 in)

158 smr2009-026

Loading...

Loading...