Section 07 BODY AND HULL

Subsection 03 (HULL)

9. Reinstall coolant hoses on ride plate fittings,

pay attention to gear clamp positioning. See

following illustration.

smr2009-043-016_b

1. Gear clamp

positioning

10. Install jet pump, refer to the

JET PUMP

sub-

section.

11. Install i

BR gate and VTS trim ring, refer to the

IBR AND VT

S

subsection.

12. Install battery and electrical accessories sup-

port, refer to

CHARGING SYSTEM

subsec-

tion.

13. Refill cooling system and carry out a leak test.

Refer to

COOLING SYSTEM

subsection.

14. Instal

l all remaining parts in the reverse order

of remo

val.

JET PUM

P SUPPORT

Jet Pump Support Removal

1. Remove

the inlet grate and ride plate, see pro-

cedur

es in this subsection.

2. Remove the four screws retaining the pump

support to the ride plate.

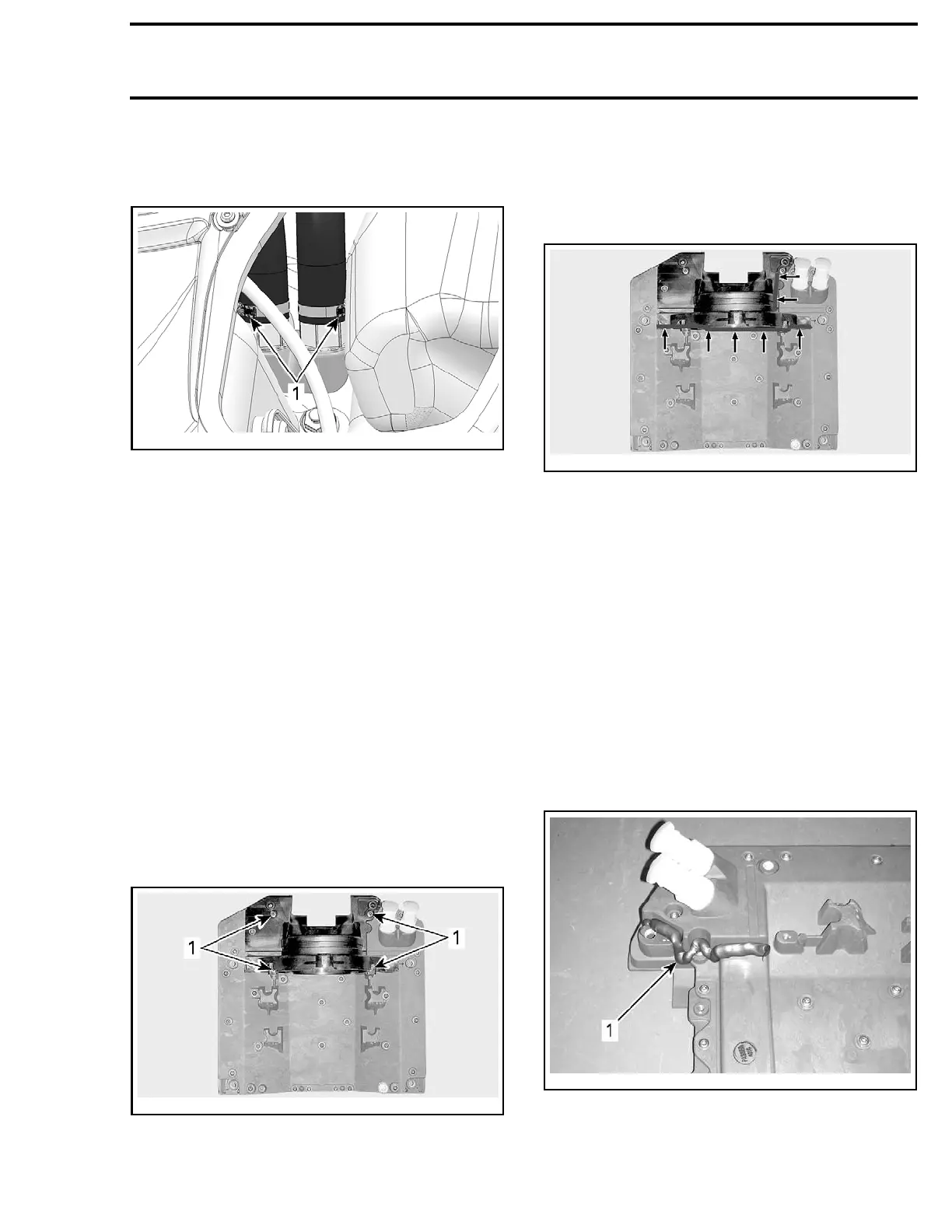

smr2009-043-019_a

TYPICAL - TOP VIEW RIDE PLATE AND PUMP SUPPORT

1. Pump support retaining screws

3. Sealant is applied between the jet pump sup-

port and the ride plate. Using a heat gun, heat

the base of the pump support to soften the

sealant and carefully pry the pump support off

therideplate.

smr2009-0

43-019_b

APPLY HEAT HERE

Jet Pump Support Cleaning

1. Scrape off all excess sealant from jet pump sup-

port, ride plate, and hull.

2. Inspect p

ump support for cracks and other

damages.

Replace as necessary.

3. Clean jet pump support and hull surface with

BRP HEAVY DUTY CLEANER (P/N 293 110 001) to

eliminate grease, dust, and sealant residue.

Jet Pump

Support Installation

1. Ensure sealant contact areas are clean and dry.

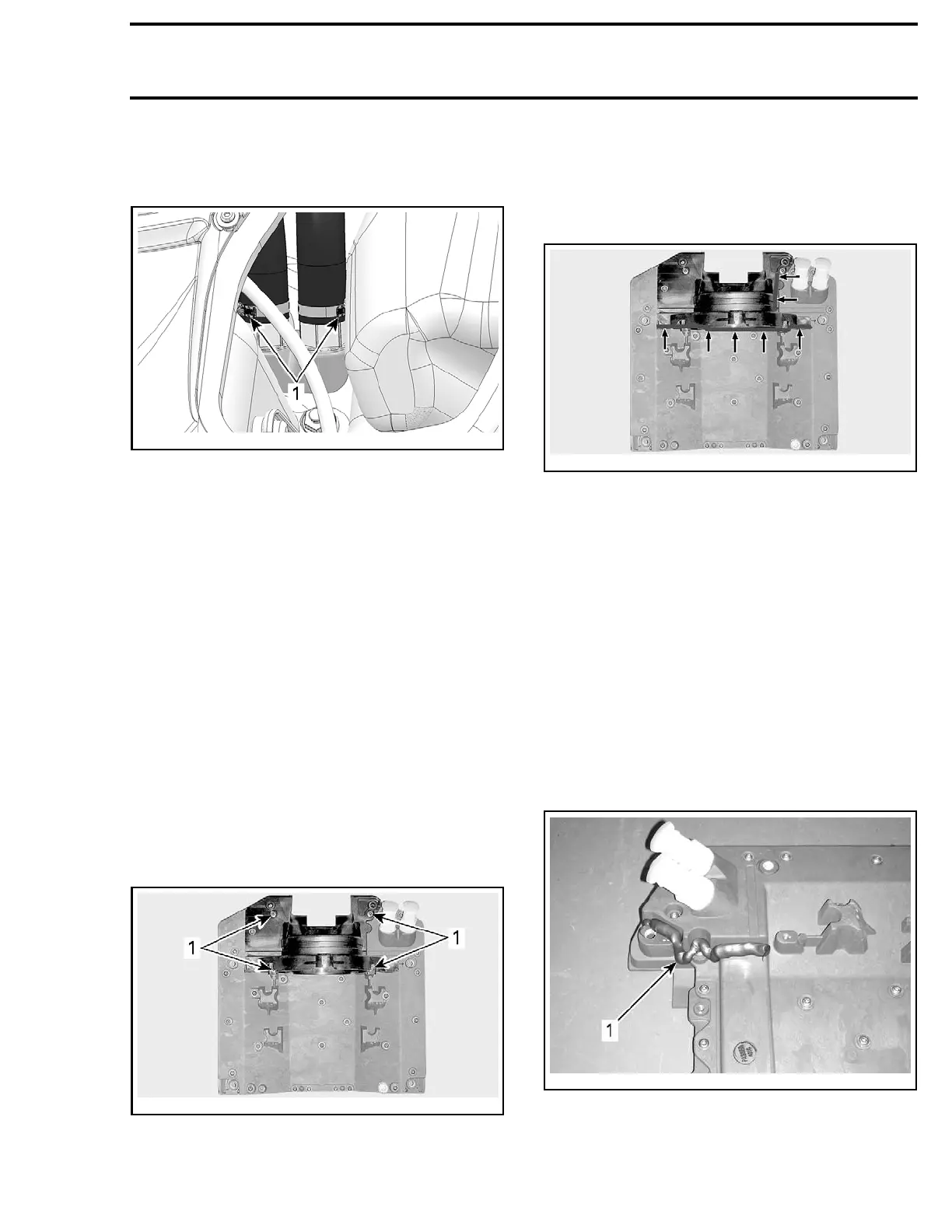

2. Apply

LOCTITE 5900 (P/N 293 800 066) on the ride

plate and pump support as seen in the following

illustrations.

smr2009-043-021_a

1. Apply loctite 5900 here

smr2009-042 503

Loading...

Loading...