Section 02 ENGINE

Subsection 10 (CYLINDER HEAD)

V01C1HA

B

A

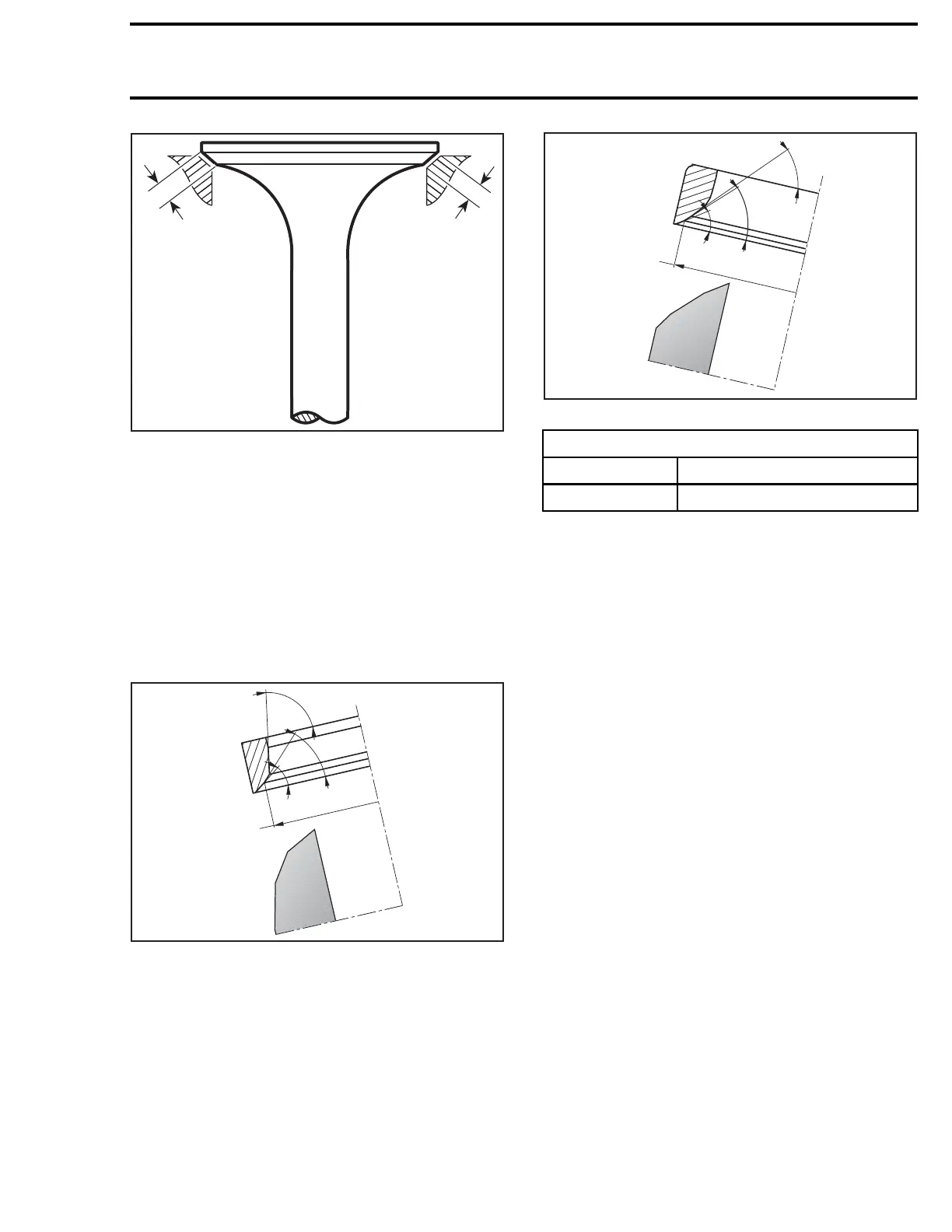

A. Valve face contact width

B. Valve seat contact width

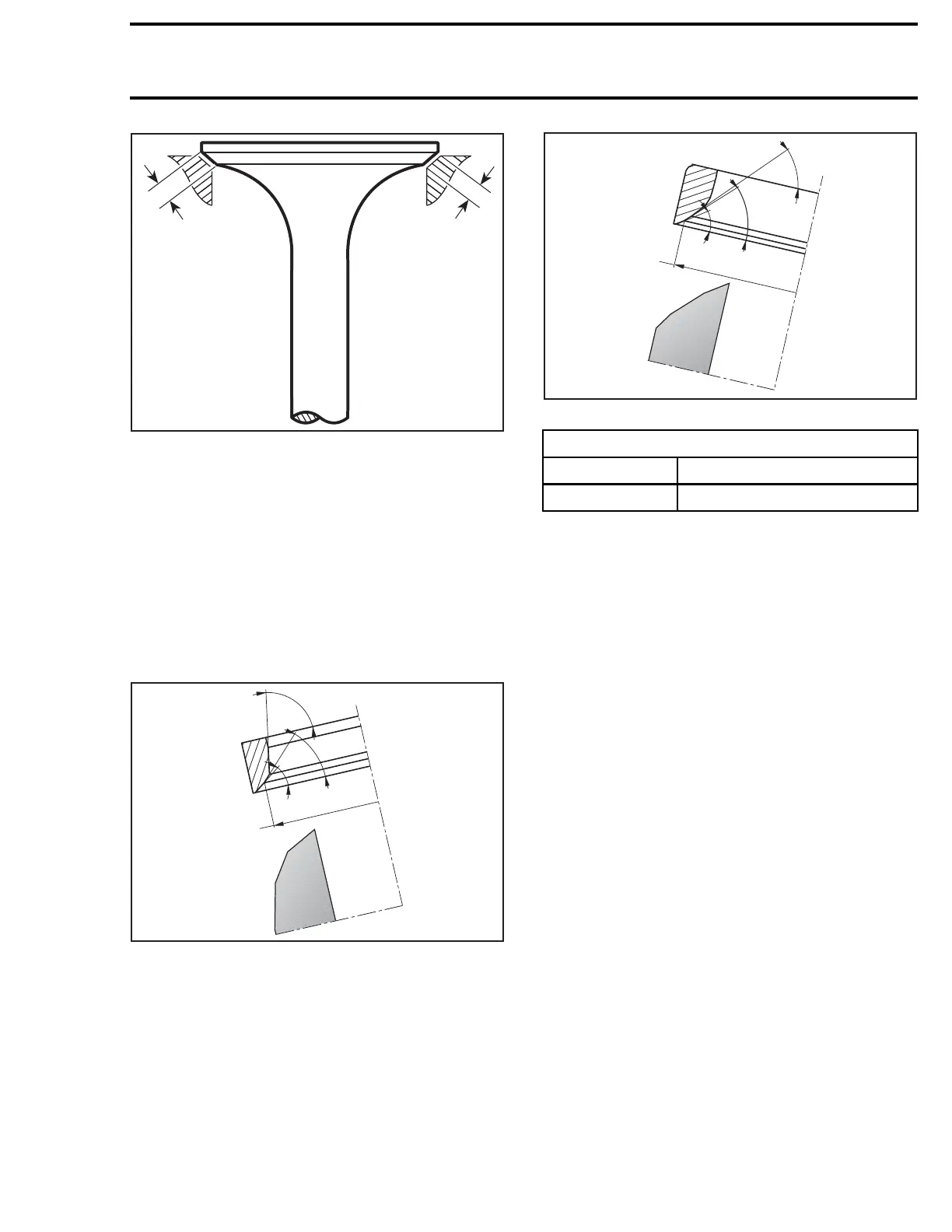

Valve Seat Grinding

NOTE: The valve seats may be reground with

a valve seat grinder which centers on the valve

guide.

1. Grind the valve seat at 45°. Remove no more

material than absolutely necessary to clean the

seat up.

2. Using a 35° stone, narrow the valve seat until

the appropriate outer diameter is obtained.

A

EXHAUST

80°

45°

35°

80°

45°

35°

R1503motr259A

A. Valve seat outer diameter EXHAUST

R1503motr260A

A

INTAKE

55°

45°

55°

45°

35°

35°

A. Valve seat outer diameter INTAKE

VALVE SEAT

OUTER DIAMETER

Intake 37.35 mm (1.4705 in)

Exhaust 30.3 mm (1.1929 in)

3. Using a 55° stone for the intake and an 80°

stone for the exhaust valve, reduce the valve

seat contact width to the appropriate value

mentioned above.

4. Finally, coat the valve seating surface with a

fine paste of valve grinding compound using a

manual valve grinding mandrel. Lightly grind

the valves until a smooth, even, uniform sealing

surface of the appropriate inside and outside

diameter is obtained on both the valve and

the seat. Use only a hand held valve grinding

mandrel with a suction cup, rotating the valve

back and forth through about 45°, and then

advancing the valve 45° before repeating this

operation.

Valve Installation

For installation, reverse the removal procedure.

Pay attention to the following details.

Inst

all NEW valve stem seal.

smr2009-025 145

Loading...

Loading...