Section 02 ENGINE

Subsection 10 (CYLINDER HEAD)

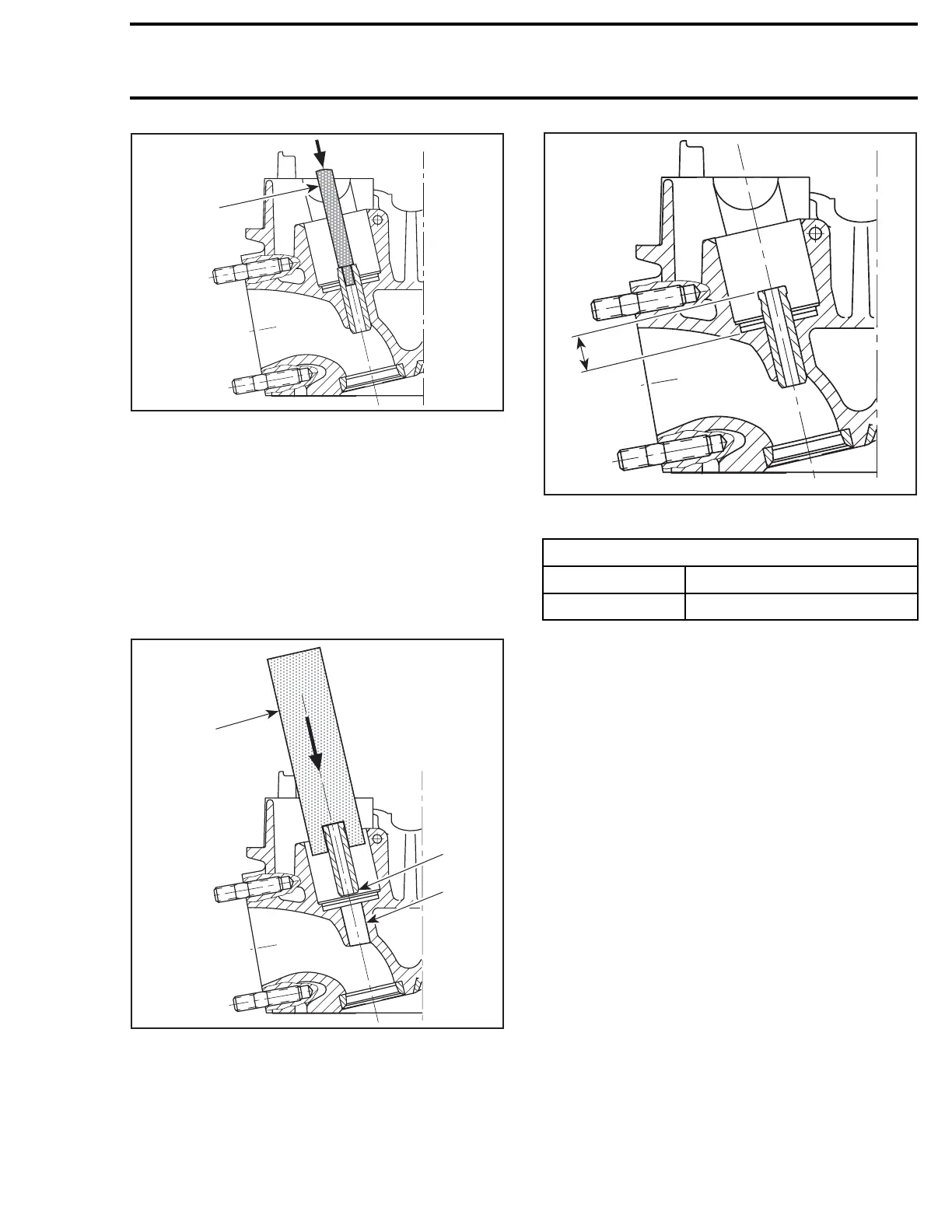

1

R1503motr255A

TYPICAL

1. Punch

Check valve guide bore for abreased material.

The inlet and exhaust valve guides have the same

length and are interchangeable.

NOTE: If valve guide has caused scoring during

extraction, replace the cylinder head.

Grease the bore in cylinder head and the leading

end of valve guide with

MOLYKOTE G-N (P/N 420

297 433)

.

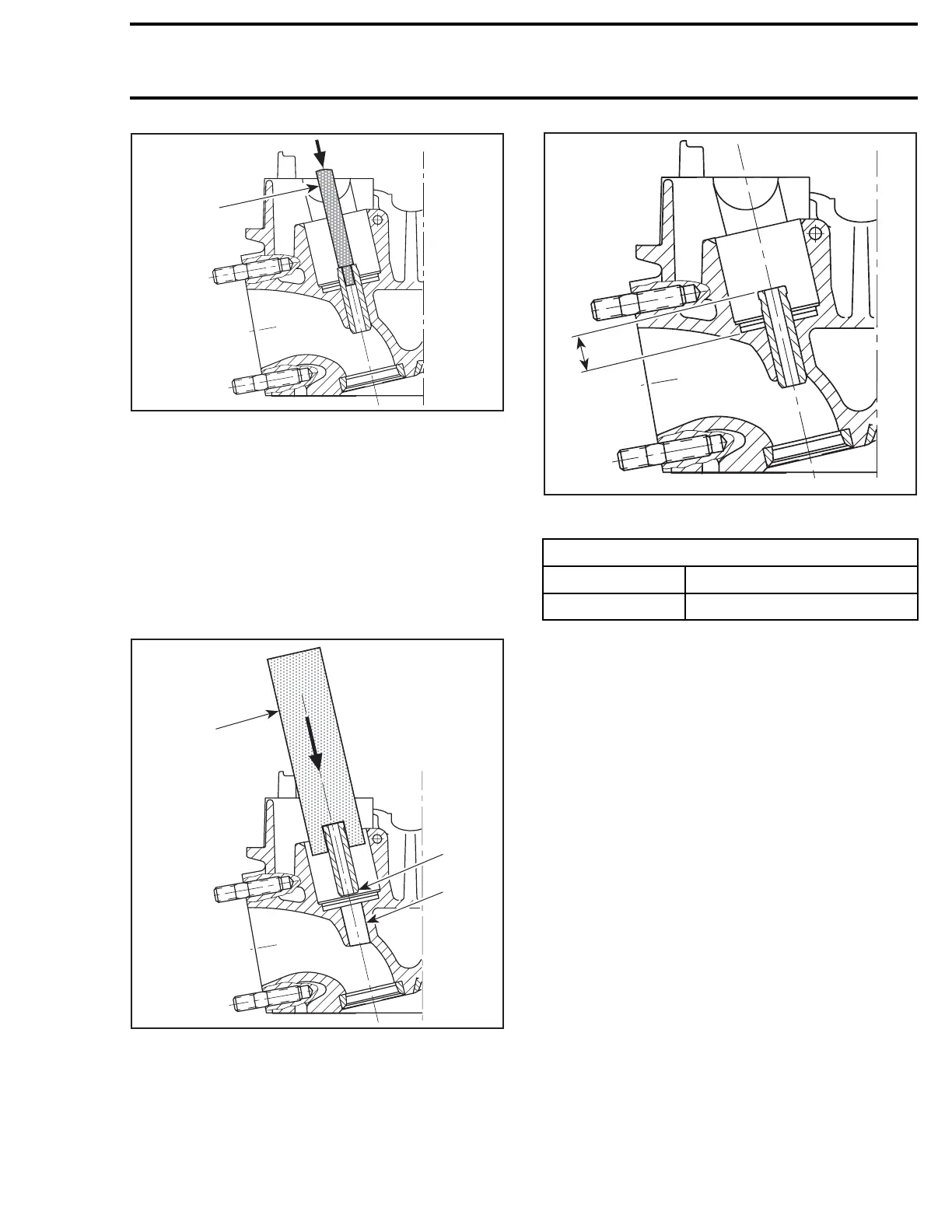

3

R1503motr256A

1

2

TYPICAL

1. Valve guide leading end

2. Cylinder head bore

3. Jig

With the VALVE GUIDE PUSHER (6 MM) (P/N 529 036

087)

, press the valve guide into the COLD cylinder

head as shown.

A

R1503motr257A

TYPICAL

A. Protrusion

VALVE GUIDE PROTRUSION

MINIMUM

12.4 mm (.4882 in)

MAXIMUM

12.8 mm (.5039 in)

NOTE: After installing new guides, they must be

reamed with a standard 6 mm reamer tool. These

are available from various tool suppliers.

Clean cy

linder head carefully. Check that the valve

seat is c

oncentric with the new guide axis (check

contact

surface with engineer's blue).

smr2009-025 147

Loading...

Loading...