Section 04 FUEL SYSTEM

Subsection 03 (FUEL TANK AND FUEL PUMP)

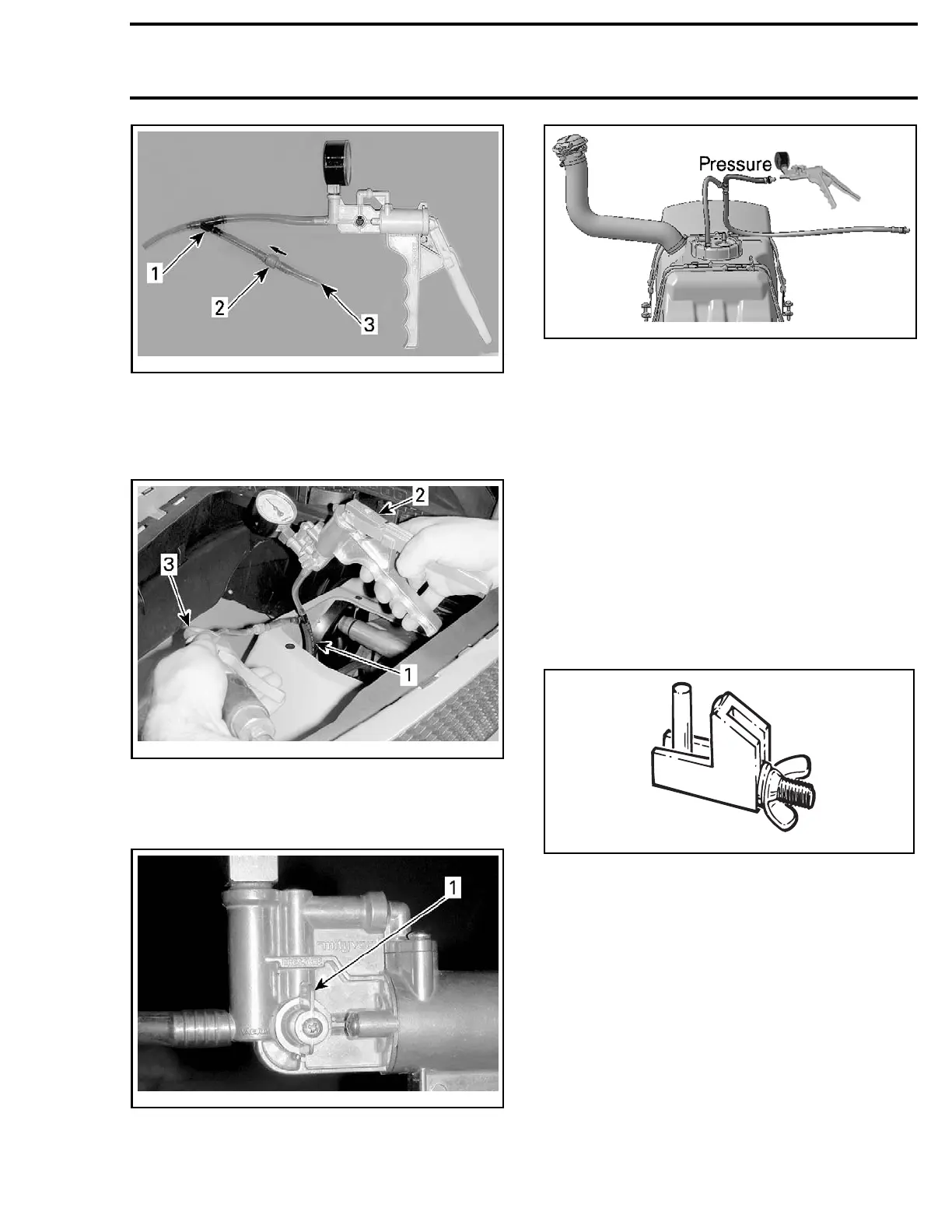

mmr2009-121-004_a

1. Y-fitting P/N 293 710 059

2. Check valve P/N 275 500 505

3. Apply compressed air here

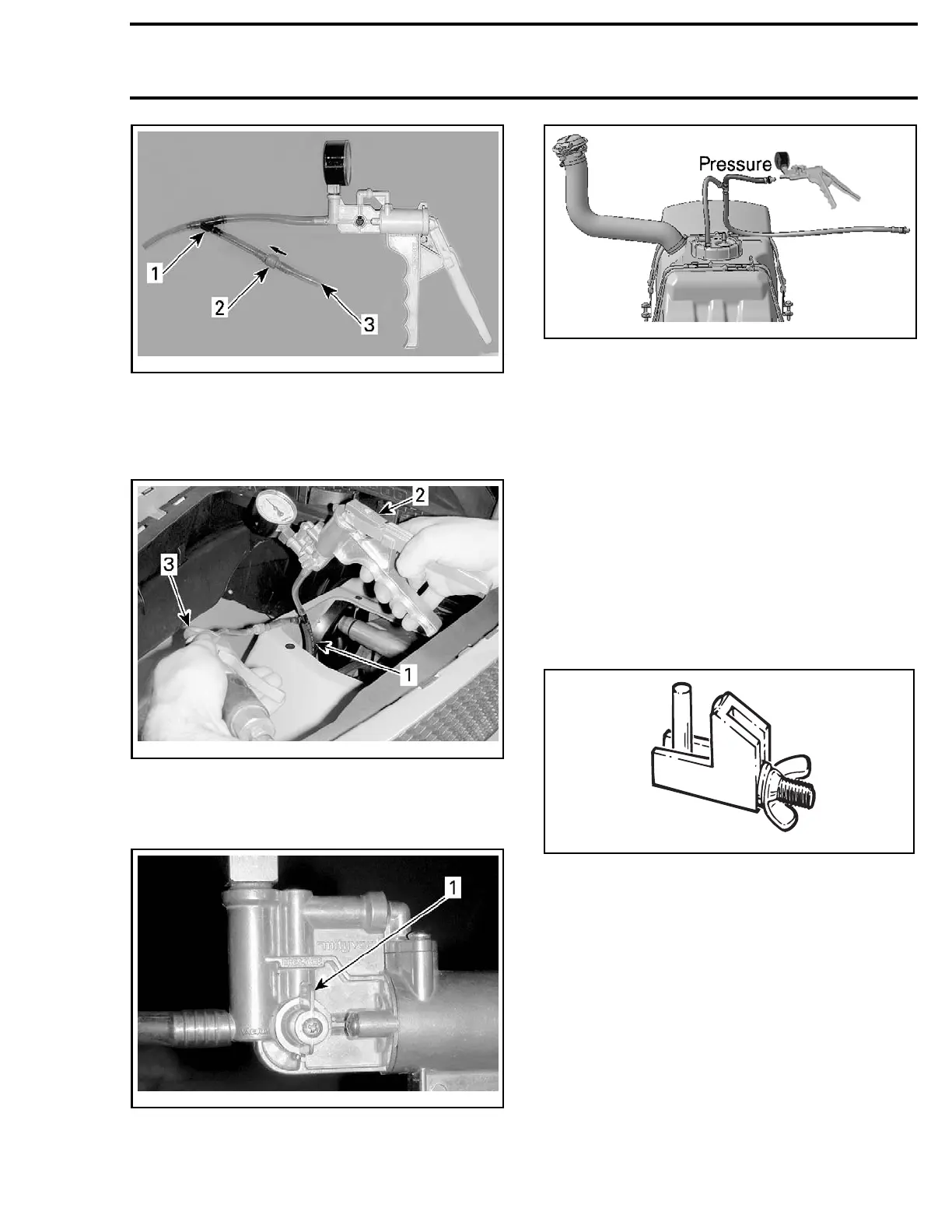

Install the vacuum/pressure gauge on inlet valve

end.

smr2009

-031-010_a

1. Inlet valve end

2. Vacuum/pressure pump

3. Compre

ssed air supply

Set vacuum/pressure pump to pressure.

smr2009-031-012_a

1. Pressure selected

smr2009-031-101_a

TEST SETUP

Slowly apply pressurized air.

NOTE: If pressure rises quickly within a few

strokes of pump, inlet valve is likely clogged.

Refer to

INLET CHECK VALVE TEST

in this sub-

section.

When pressure has reached 2.8 kPa - 7.6 kPa

(.4 PSI - 1.1 PSI) the pressure relief valve should

open preventing a further increase in pressure.

When valve opens, pressure must drop at pump

gauge.

If pressure increases above specification or gauge

does not drop to zero, replace outlet valve.

Install a

SMALL HOSE PINCHER (P/N 295 000 076)

near outlet valve.

2950000

76

NOTE: To validate outlet hose, connection and

valve altogether, a test cap (P/N 293 000 105) or

an equivalent hand made plug (such as a capped

vent hose) can be installed to the outlet nipple of

the valve.

smr2009-031 259

Loading...

Loading...