90 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Assembly and Installation

Subject to change without notice

Function test emergency air operation with instrument air

Make a compressed air connection between the junction box for solenoid valve (2) and

emergency air valve (3) as shown in (

p. 87, Fig. 57).

Separate the emergency air valve from the cooling air hoses and S/R units.

Switch the MCU supply voltage off - solenoid valve (2a) must switch audibly and release

the instrument air flow.

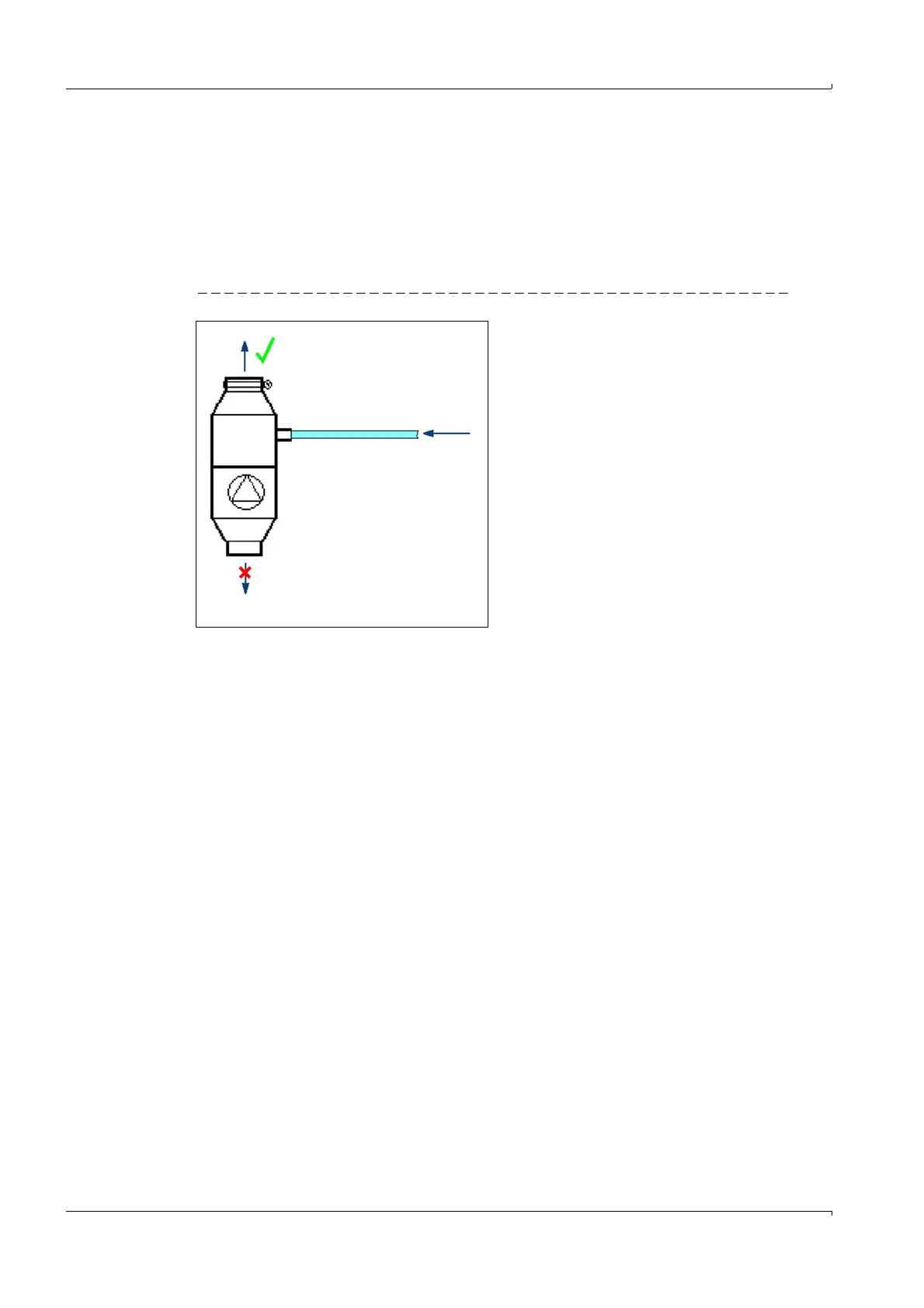

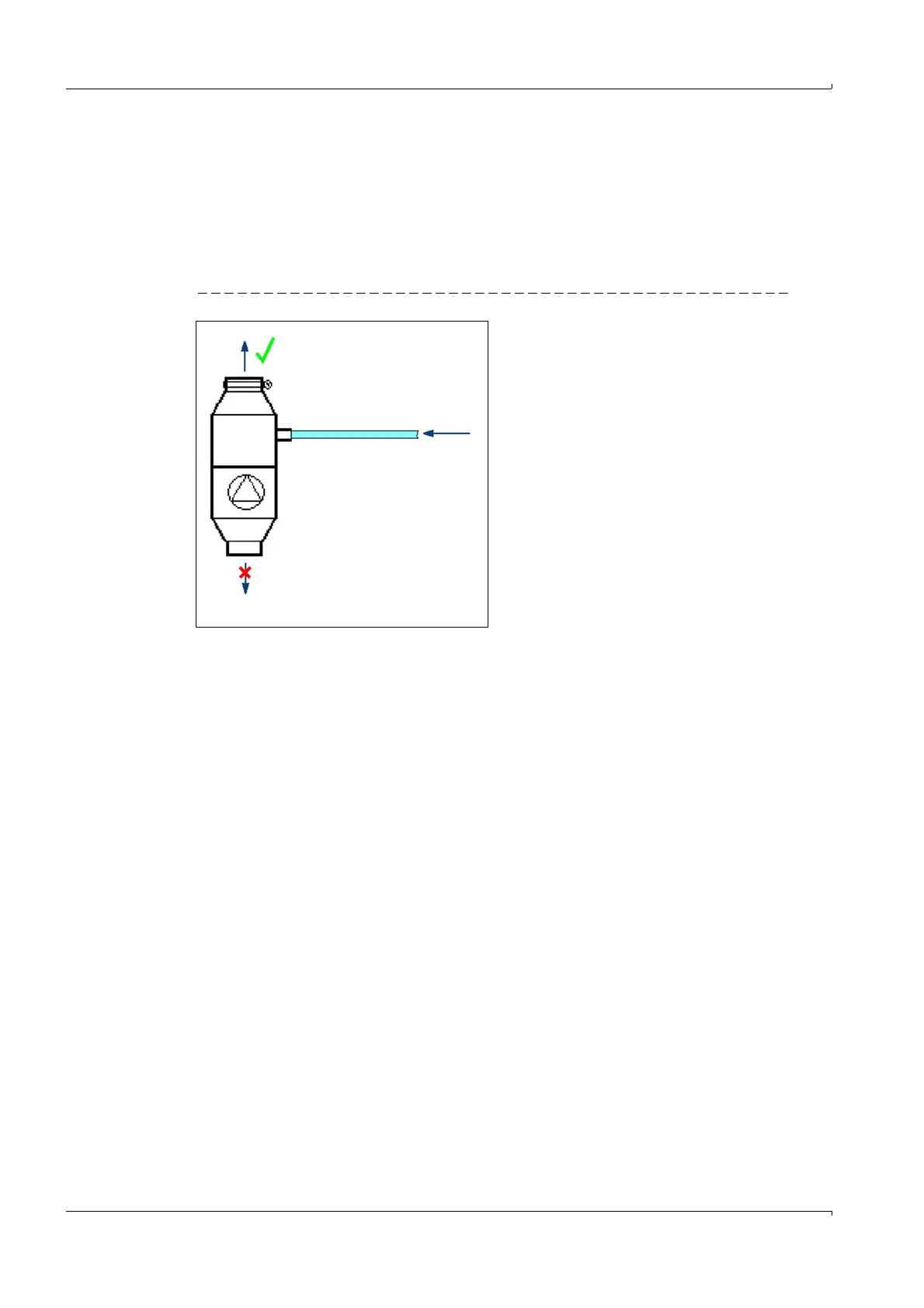

Emergency air flow direction test - see (

Fig. 60).

Fig. 60 Emergency air direction test

The air flow in flow direction must be noticeable (approx. 2.8 l/s). No significant leakage

flow should flow in the blocking direction (

Fig. 60). Leakage rates up to 3% of the nominal

air flow are allowed.

Repeat the test shown in Fig. 60 with the S/R unit connected (

p. 87, Fig. 57). The escaping

air should still also be clearly felt on the probe exhaust slots (

p. 87, Fig. 57).

Finally, reconnect all connections as shown in (

p. 87, Fig. 57), reset any changed

parameters and set the device to the operating state.

Maintenance

The emergency air supply should be able to bridge temporary cooling air failures up to 24

hours. Measuring operation could be interrupted during this time (noise disturbance due to

increased instrument air noise).

It is recommended to take the S/R units out of the sample gas duct during longer term

restrictions or complete failure of the standard cooling air supply.

Check parts carrying air as shown in (

p. 87, Fig. 57) after longer emergency air operation:

Remove the DN 25 cooling air hoses and check the insides for condensate, oil and

general contamination. Clean the insides of the hoses when necessary and replace

hoses with heavy contamination. Use hoses with the same length for both S/R units.

Remove the emergency air valves and open to check (

p. 89, Fig. 59).

Remove any contamination and dry the valve, replace emergency air valve (3) when

contamination is heavy or when the valve is damaged (spring, valve plate, rubber seal).

Apply talcum powder to the dry rubber seal of the valve plate to prevent the valve plate

sticking in the seating.

Carry out the opening and blocking direction function check as shown in (

p. 90, Fig.

60).

Direction test

emergency air

Flow direction

Blocking direction

Loading...

Loading...