Assembly and Installation

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH 91

Subject to change without notice

Remove the DN25 cooling air hoses from the MCU outlet and check the MCU outlet for

any moisture inside (possibly from compressed air, leakage flow).

Open the air filter housing in the MCU and check the paper filter element.

Replace the filter element when penetrated by moisture or extremely contaminated - air

filter replacement - analog OI Section 5.3.

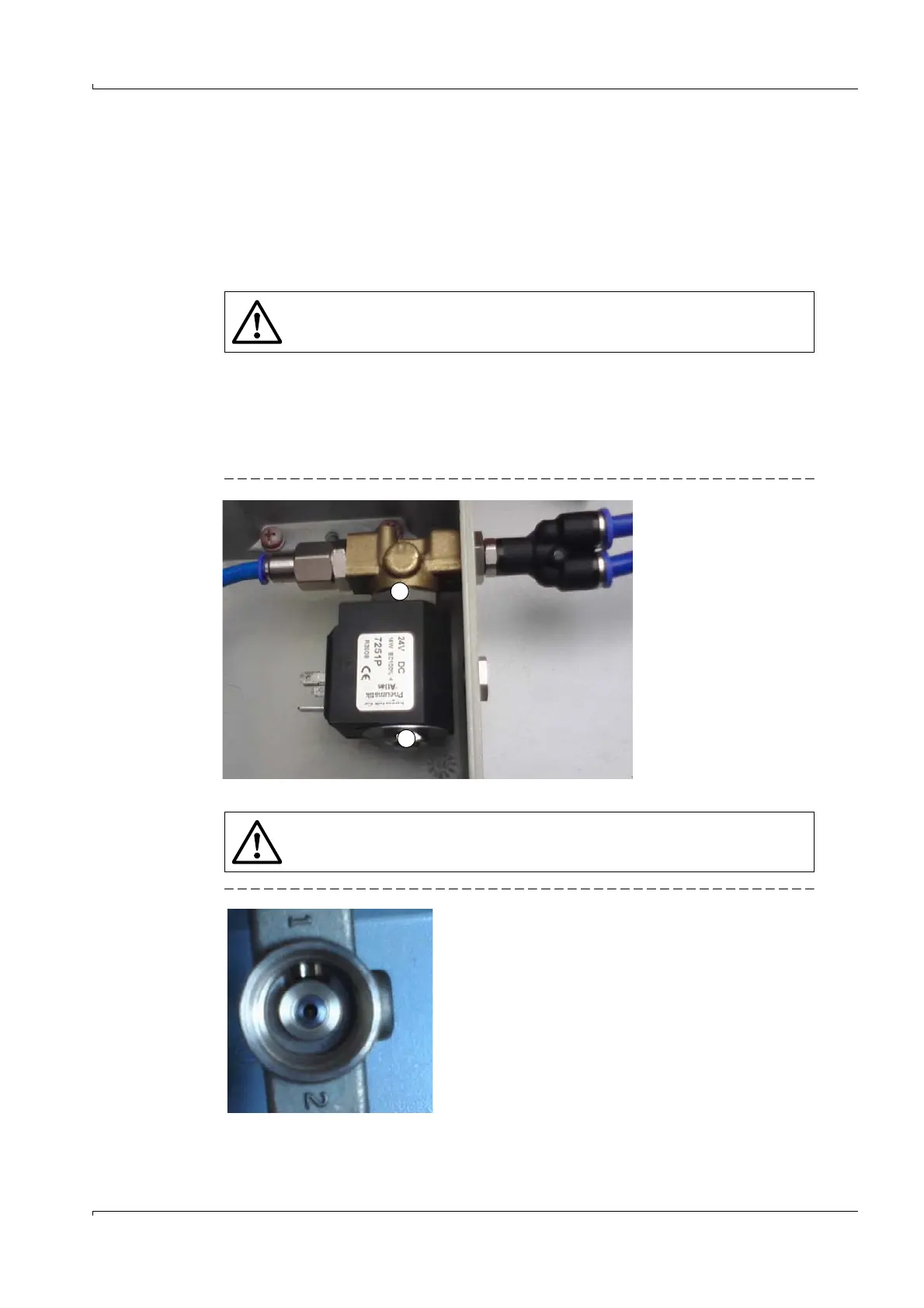

Solenoid valve maintenance/repairs

Open the junction box for the solenoid valve.

Test switch the solenoid valve with varying compressed air primary pressures (1...3 bar).

Should valve switching fail, use central screw (1) (

p. 91, Fig. 61) on the solenoid switch

to open the valve.

Screw the tension rod out above hexagon (2) (

p. 91, Fig. 61).

Fig. 61 Opening the solenoid valve

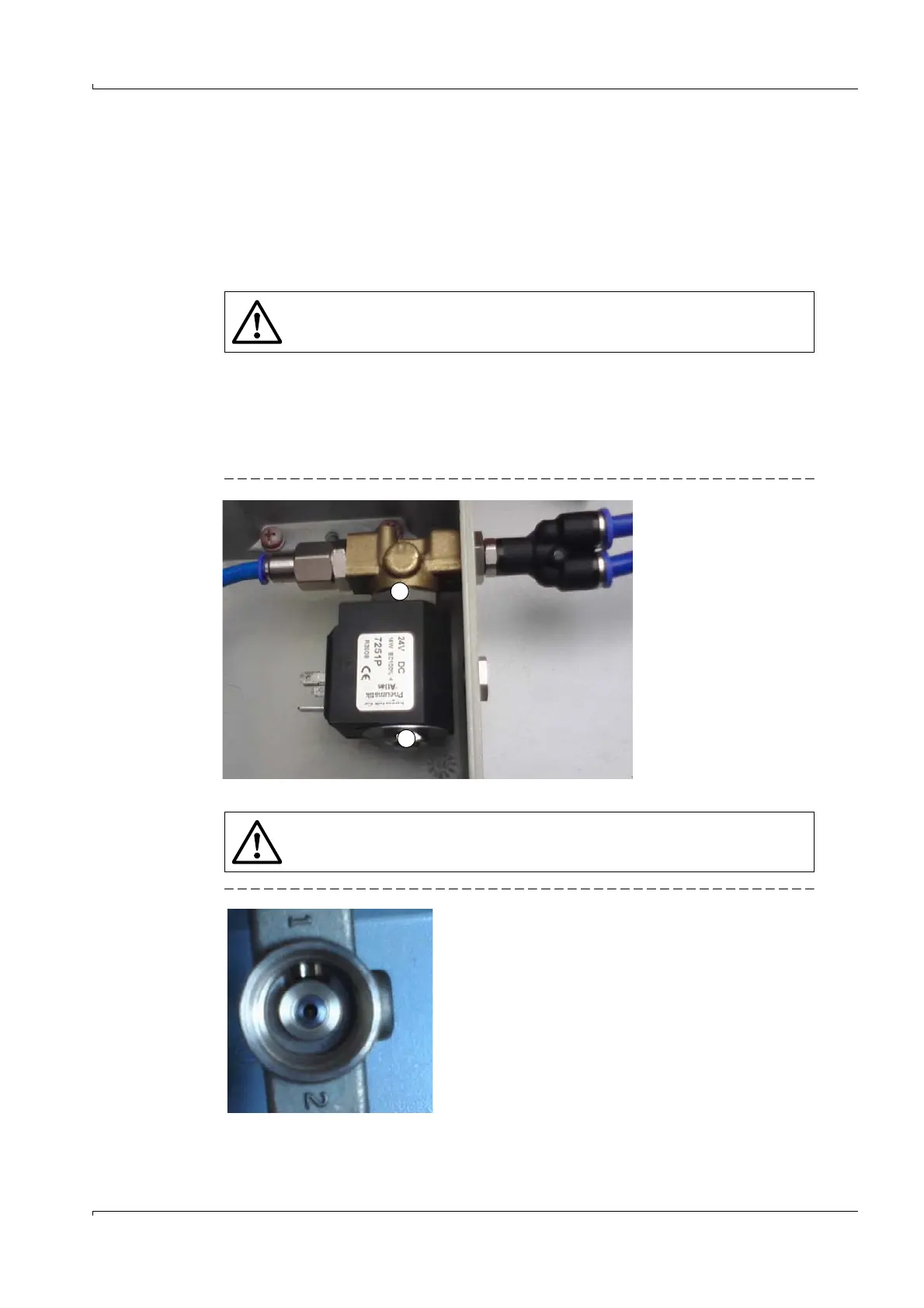

The valve seating is now open (

Fig. 62) and can be cleaned when necessary.

Fig. 62 Valve seating / sealing surface in solenoid valve

Replace the complete solenoid valve when heavily contaminated and/or corroded.

WARNING:

The solenoid valve surface can be hot (> 70°C).

2

1

1. Solenoid valve central screw

2. Hexagonal solenoid valve

WARNING:

Do not use any sharp objects.

Loading...

Loading...