96 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Assembly and Installation

Subject to change without notice

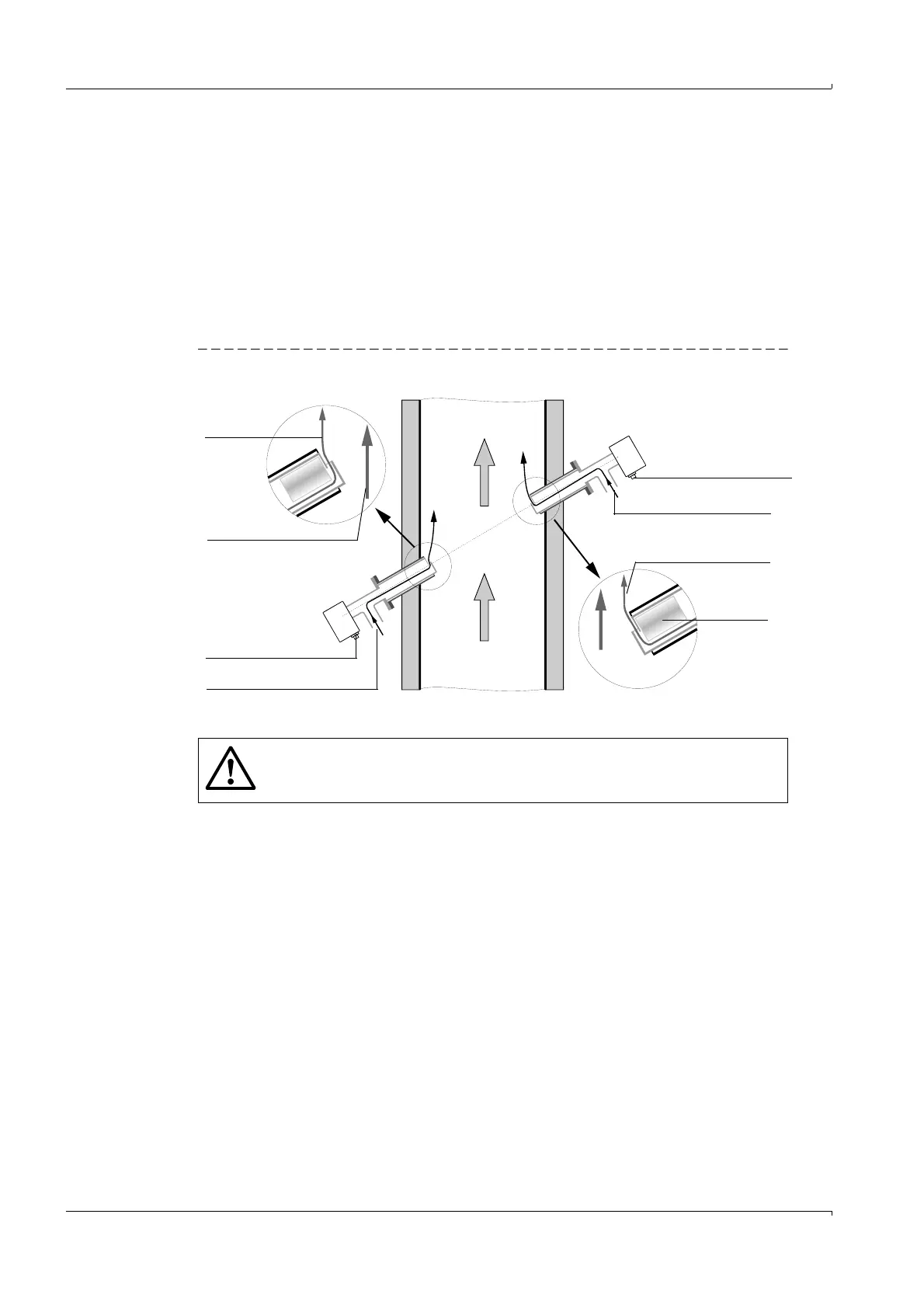

Purge air supply for purged sender/receiver units FLSE100-PM, PH, PHS

To minimize corrosion when using corrosive gases, ensure the nominal lengths of the

sender/receiver units are at least one length longer than the nominal lengths of the

flanges with tube (

p. 27, 2.3.1.3).

Check/ensure the purge air supply is in operation.

Connect the purge air hoses, to do this, connect the hose clamp loosely on the free

hose end, connect the purge air hose to the purge air connection on the sender/

receiver units, and secure it with the hose clamp.

Check/ensure the purge air is fed from below and the purge air flows out in the direc-

tion of the gas flow.

Fig. 67 Alignment of cable connection and purge air supply for purged sender/receiver units (shown for type

FLSE100 PM/PH, fitted on a vertical duct)

Installation and electrical connection

Remove the blind plug from the flange.

Insert the sender/receiver units in the flanges with tube as previously described and

screw the components together.

Connect the cable to the control unit to the plug-in connector on the sender/receiver

unit.

Duct

Gas flow

Ultrasonic

transducer

Discharged

purge air

Gas flow

Cable connection

Purge air feed

Cable connection

Purge air feed

Discharged

purge air

WARNING:

Only install the sender/receiver units when it is safe to do so (for example,

when the system has been shut down, see

p. 9, 1.3.3).

Loading...

Loading...