Chapter 6 Operating instructions

S3000

98 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8009942/WK81/2012-11-28

Subject to change without notice

Electrical installation

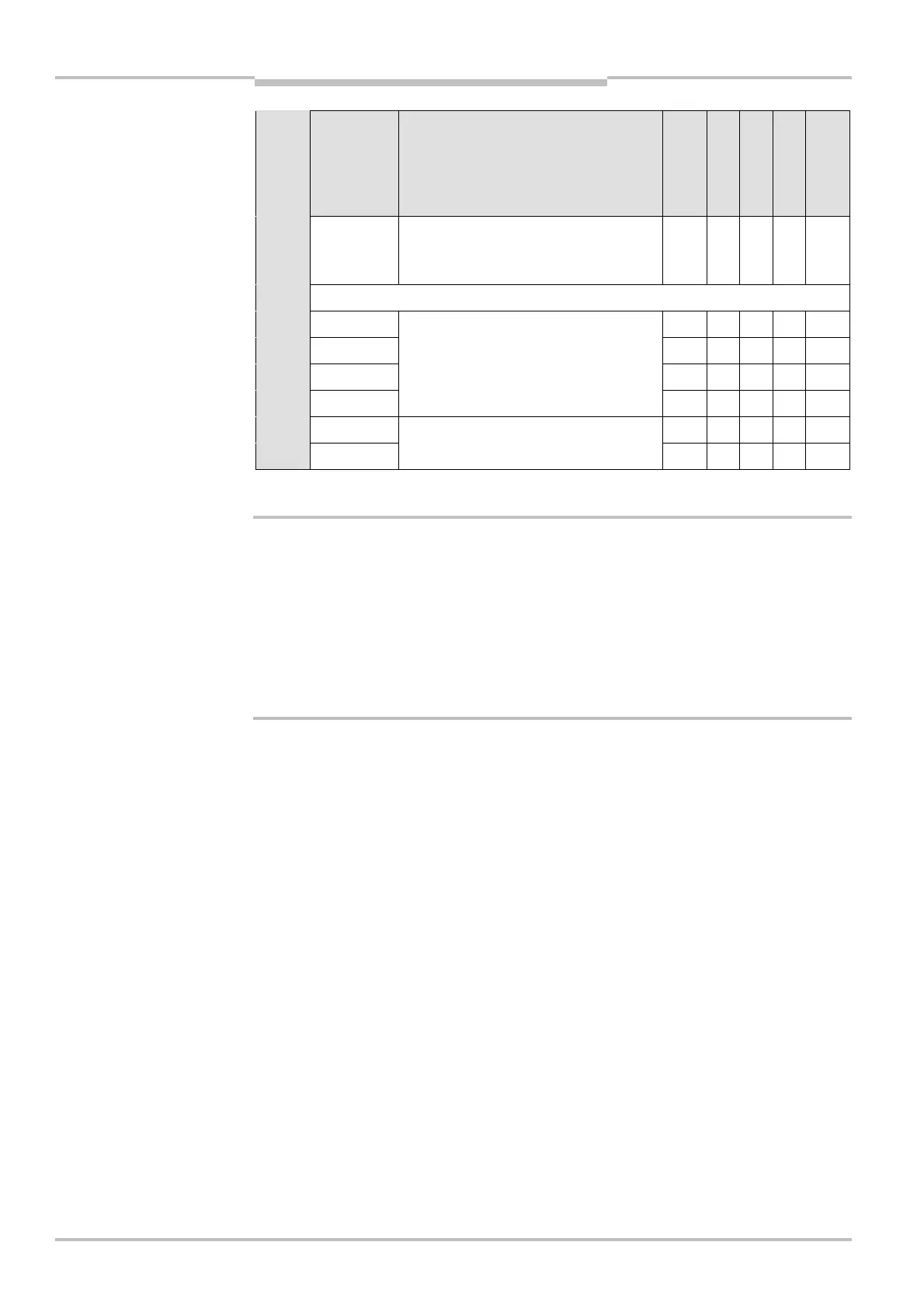

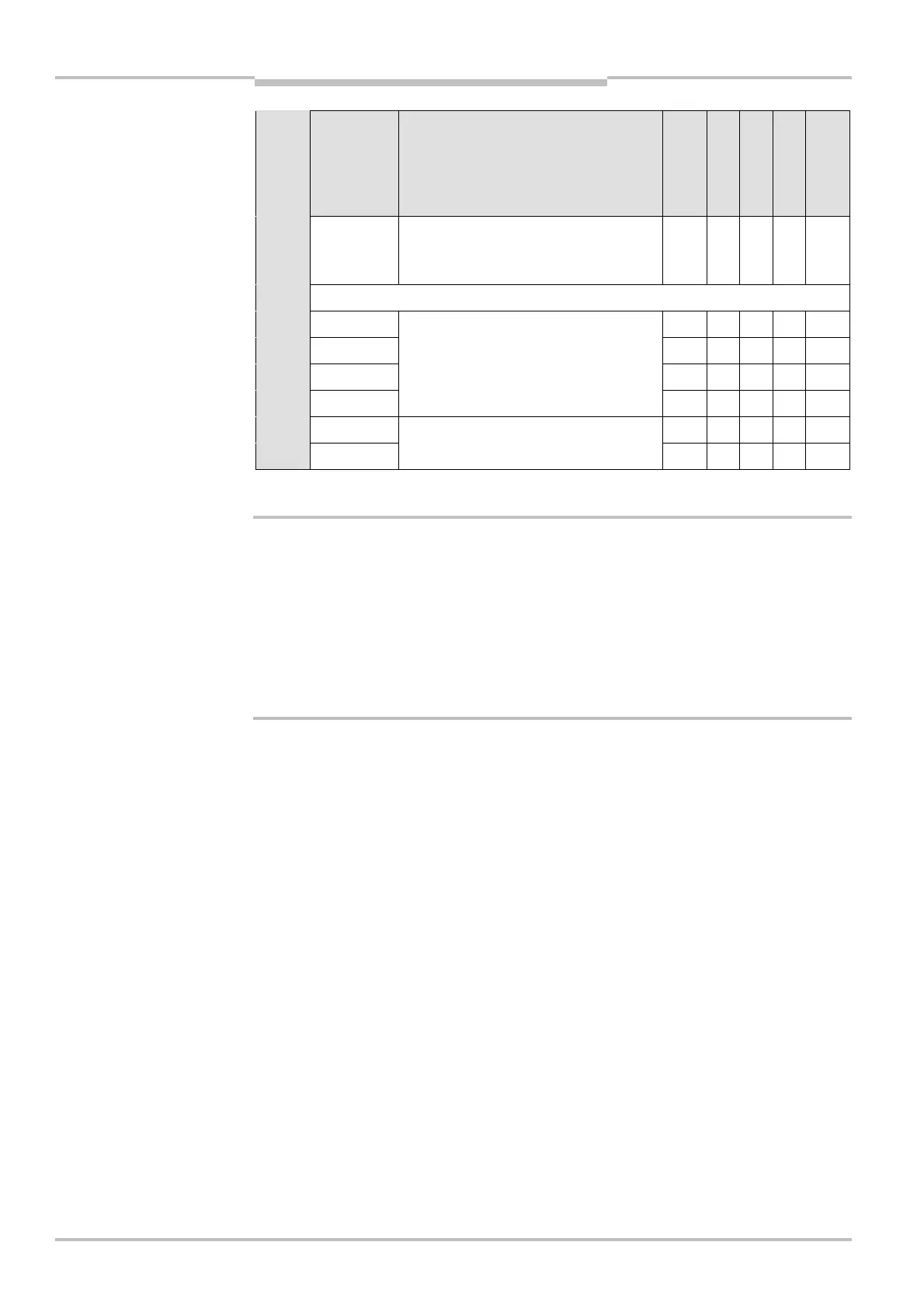

Pin Signal Function

Standard

Advanced

Professional

Expert

Remote

23 D2 or

INC2_90

Static control input D or dynamic

control input (incremental encoder

input) 2

24 Reserved, do not use!

25 RxD–

26 RxD+

27 TxD+

28 TxD–

RS<422 interface for output of

measured data

29 EFI

A

30 EFI

B

Enhanced function interface =

safe SICK device communication

Incremental encoder specification

Never supply both incremental encoders using one supply cable!

The connection cables for the incremental encoders must each be in a separate plastic-

sheathed cable as otherwise a cable break could cause an error that could remain

undetected.

The power supply to the two incremental encoders must be independent. For this

purpose use the connection terminals provided, 16 and 17 as well as 20 and 21.

Each incremental encoder output (for 0° or 90°) is only allowed to be connected to one

control input, e.g. C1/D1 or C2/D2.

Both incremental encoders must meet the following specifications:

two-channel rotary encoder with 90° phase offset

supply voltage: 24 V DC

outputs: push/pull outputs

enclosure rating IP 54 or better

screened cable

max. pulse frequency: 100 kHz

min. number of pulses: 50 pulses per cm

You can procure suitable incremental encoders from SICK AG, tel.: +49 211/5301-250 or

at www.sick.com. Or contact your local SICK representative.

Control inputs

You can only connect the input signals to one safety laser scanner. Distributed connection

of the input signals to two safety laser scanners is not possible.

WARNING

Recommendation

Loading...

Loading...