Chapter 3 Operating instructions

S3000

18 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8009942/WK81/2012-11-28

Subject to change without notice

Product description

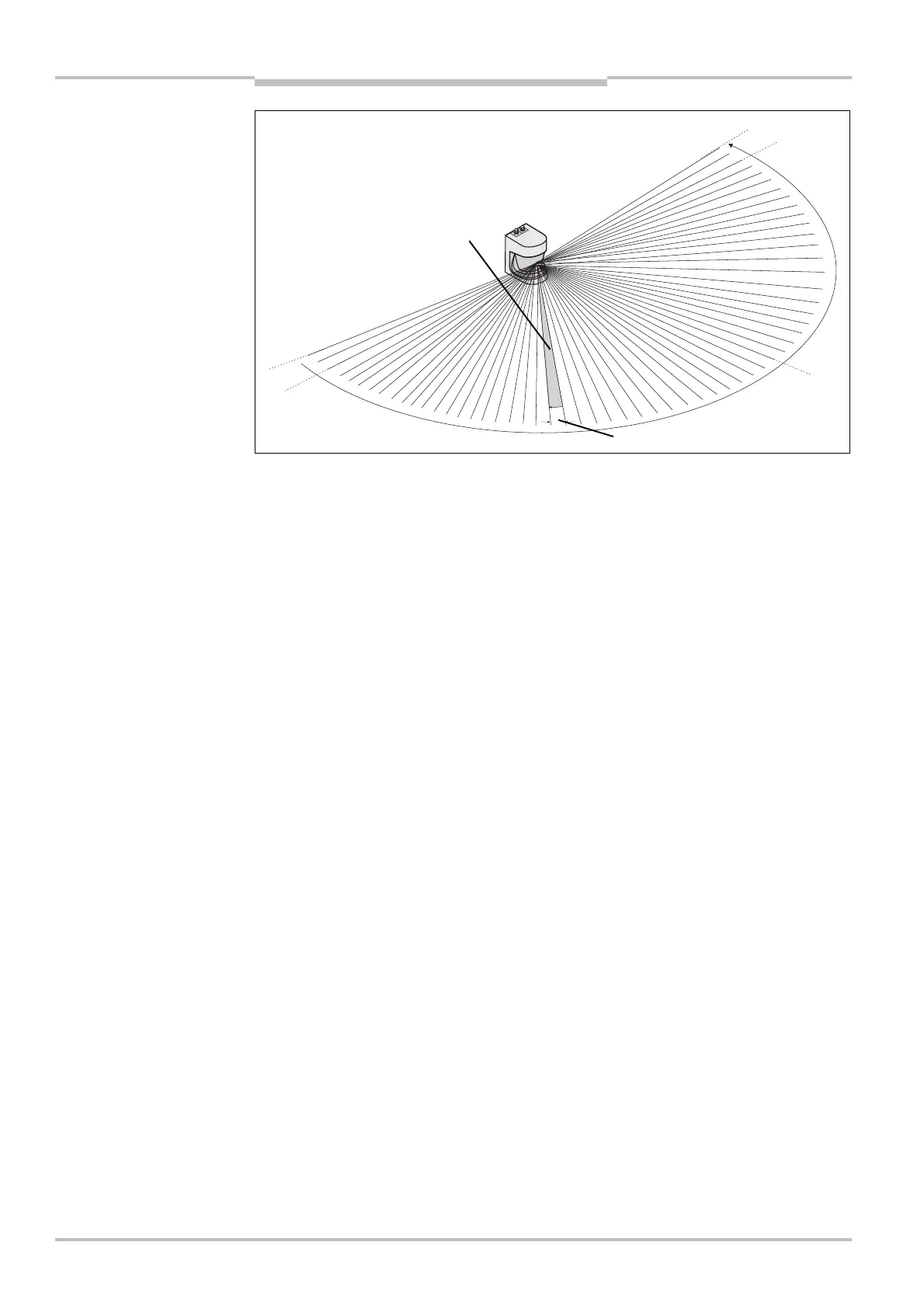

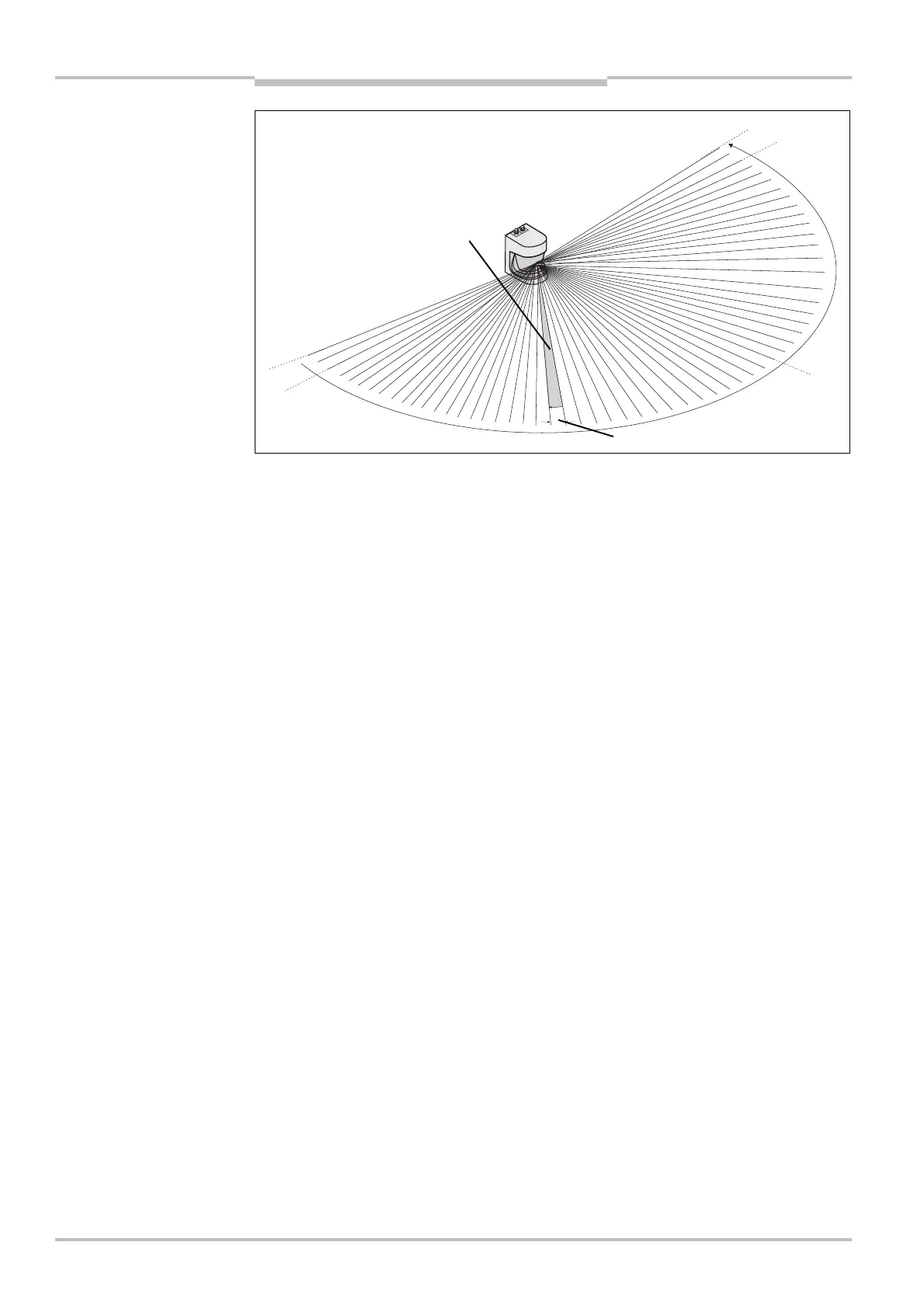

In the S3000 there is also a mirror rotating at constant speed that deflects the light pulses

such that they cover an arc of 190°. In this way an object can be detected in the protec-

tive field within 190°. The first beam of a scan starts at –5° relative to the back of the

scanner.

The S3000 sends its pulses of light with an angular resolution of 0.25° or 0.5° . As a

result resolutions between 30 mm and 150 mm can be achieved .

Due to its active scanning principle, the S3000 does not require receivers or reflectors.

This has the following advantages:

Your installation effort is lower.

You can easily adapt the monitored area to the hazardous area on a machine.

In comparison with contact sensors, electro-sensitive scanning is nearly wear-free.

3.2.2 Field set comprising of protective field and warning field(s)

Protective fields and warning fields form the so-called field set. You can configure these

field sets with the aid of the CDS. The fields can be configured as circular, rectangular or of

arbitrary shape. If the area to be monitored changes, then you can re-configure the S3000

in software without additional mounting effort.

Depending on the I/O module used (see section “I/O modules” on page 22) you can

define up to 32 different field sets and save these in the safety laser scanner. In this way

you can switch to a different field set in case of a change in the monitoring situation (see

section 3.2.3 “Monitoring cases” on page 20).

You can configure different field sets:

field sets consisting of one protective field and one warning field

field sets consisting of two protective fields

field sets consisting of one protective field and two warning fields

The protective field secures the hazardous area on a machine or vehicle. As soon as the

safety laser scanner detects an object in the protective field, the S3000 switches the

OSSDs to the off status and thus initiates the shutdown of the machine or stop of the

vehicle.

rotation of the S3000

Loading...

Loading...