1PosSSI/Digital

5.9 Control and Feedback Signals

ET 200S Positioning

236 Operating Instructions, 05/2007, A5E00124871-04

5.9 Control and Feedback Signals

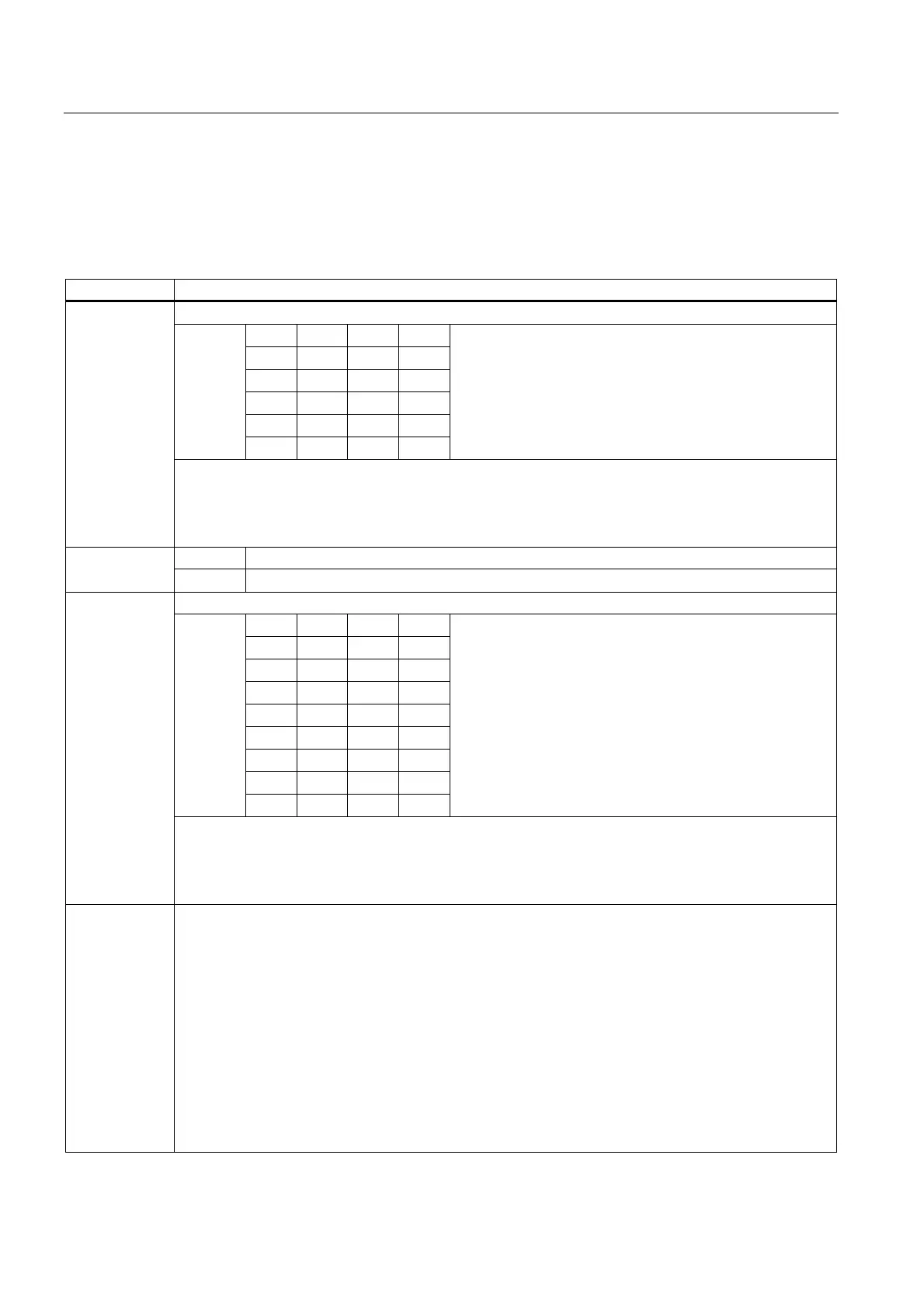

Assignment of the Control Interface

Address Assignment

Bits 0.7 to 0.4 stand for the MODEs

7 6 5 4

0 0 0 0

0 0 0 1

0 0 1 1

0 1 0 0

Bit

0 1 0 1

MODE 0 = Stop

MODE 1 = Inching

MODE 3 = Reference Point Run

MODE 4 = Relative Positioning

MODE 5 = Absolute Positioning

Byte 0

Bit 3: SPEED (SPEED = 0 is creep feed; SPEED = 1 is rapid feed)

Bit 2: DIR_M

Bit 1: DIR_P

Bit 0: START

at MODE 4 = Relative positioning: distance Bytes 1 to 3

at MODE 5 = Absolute positioning: target

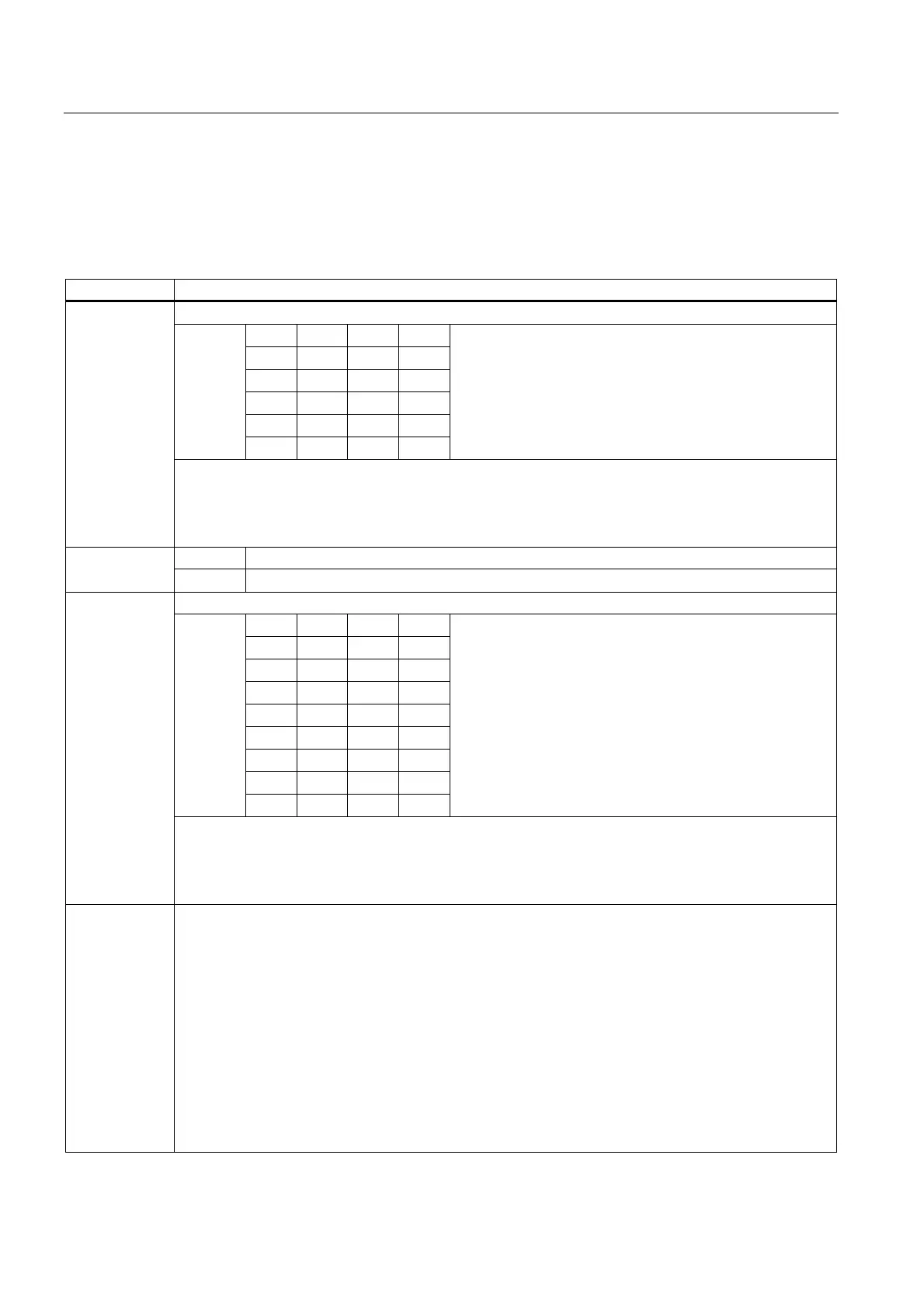

Bits 4.7 to 4.4 stand for the MODEs

7 6 5 4

0 0 0 0

0 0 0 1

0 0 1 0

0 0 1 1

0 1 0 0

1 0 1 0

1 0 1 1

Bit

1 1 1 1

JOB 0 = Cancel JOB processing

JOB 1 = Set the actual value

JOB 2 = Move encoder range

JOB 3 = Change the switch-off difference

JOB 4 = Change the switchover difference

JOB 10 = Latch function

JOB 11 = Set the monitoring of the direction of rotation

JOB 15 = Display current values

Byte 4

Bit 3: EXTF_ACK

Bit 2:Reserve = 0

Bit 1: Reserve = 0

Bit 0: JOB_REQ

Bytes 5 to 7 Corresponding to the selected JOB:

• With JOB 1= actual value coordinates

• With JOB 3 = switch-off difference

• With JOB 4 = switchover difference

• With JOB 10

– Byte 5: Bit 0 = latch at positive edge at DI2

– Byte 5: Bit 1 = latch at negative edge at DI2

• With JOB 11 = path difference for direction of rotation monitoring

• With JOB 15

– Byte 5: 0 = Residual distance

– Byte 5: 1 = Actual speed

– Byte 5: 2 = error information

Loading...

Loading...