D-1

S7-200 Programmable Controller System Manual

A5E00066097-02

S7-200 Troubleshooting Guide

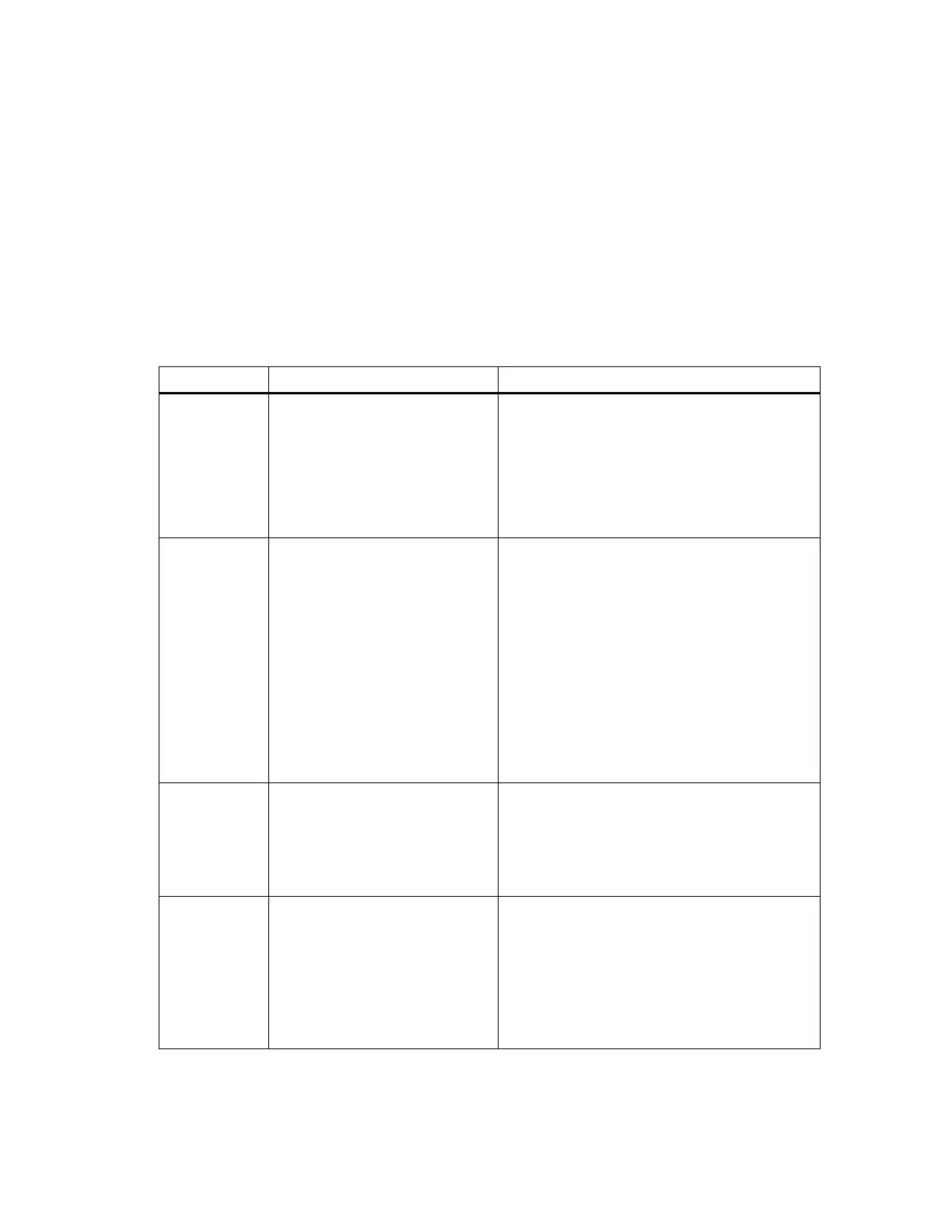

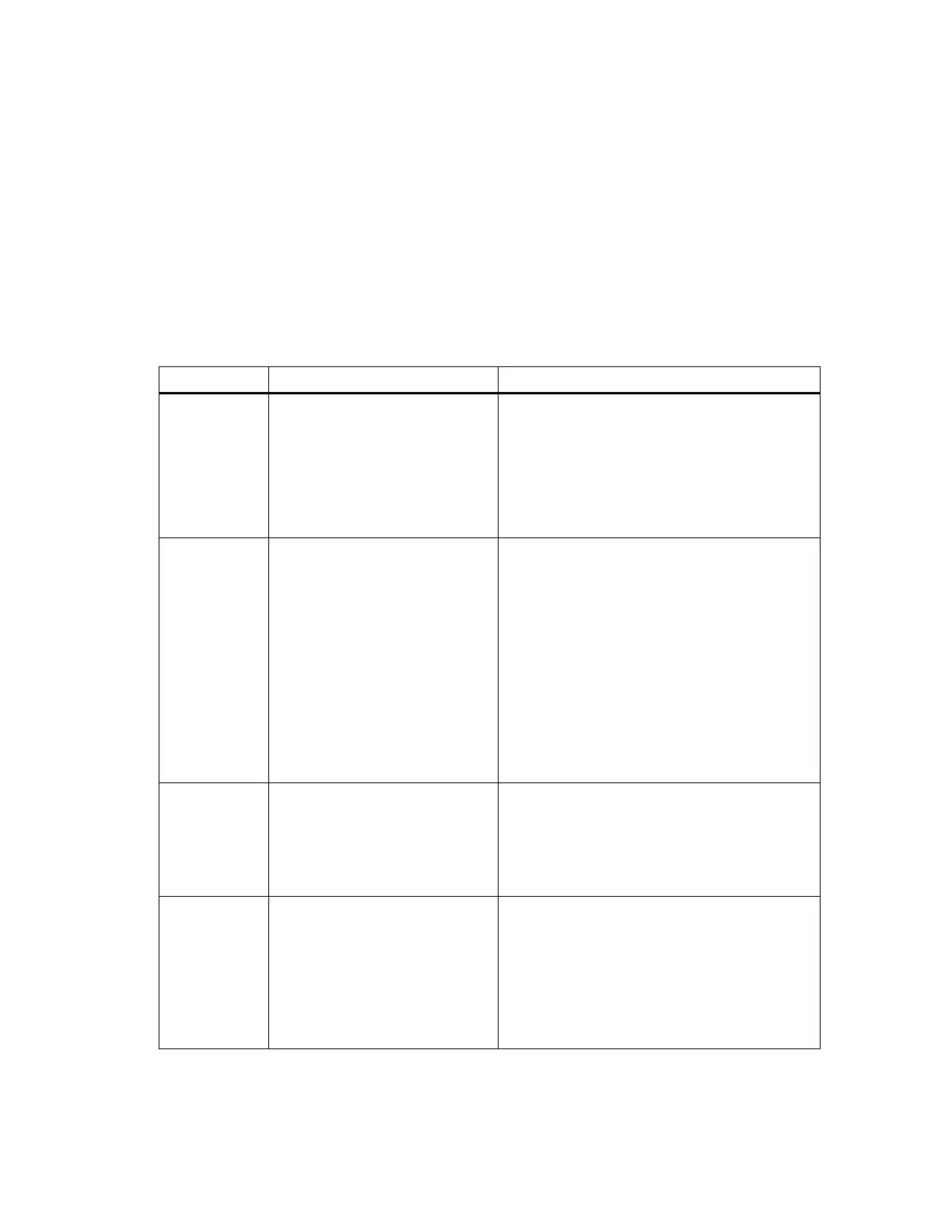

Table D-1 S7-200 Troubleshooting Guide

Problem

Possible Causes Solution

Outputs stop

working.

• The device being controlled

has caused an electrical surge

that damaged the output.

• User program error

• Wiring loose or incorrect

• Excessive load

• Output forced points

• When connecting to an inductive load (such

as a motor or relay), a proper suppression

circuit should be used. Refer to Section 2.4.

• Correct user program

• Check wiring and correct

• Check load against point ratings

• Check CPU for forced I/O

CPU SF

(System Fault)

light comes on.

The following list describes the

most common causes:

• User programming error

– 0003 Watchdog error

– 0011 Indirect addressing

– 0012 Illegal floating point

value

• Electrical noise

– 0001 through 0009

• Component damage

– 0001 through 0010

Read the fatal error code number and refer to

Section B.1:

• For a programming error, check the usage of

the FOR, NEXT, JMP, LBL, and Compare

instructions.

• For electrical noise:

– Refer to the wiring guidelines in

Section 2.3. It is very important that the

control panel is connected to a good

ground and that high voltage wiring is not

run in parallel with low voltage wiring.

– Connect the M terminal on the 24 VDC

Sensor Power Supply to ground.

Power supply

damaged.

Over-voltage on the power lines

coming to the unit.

Connect a line analyzer to the system to check

the magnitude and duration of the over-voltage

spikes. Based on this information, add the proper

type arrestor device to your system.

Refer to the wiring guidelines in Section 2.3 for

information about installing the field wiring.

Electrical noise

problems

• Improper grounding

• Routing on wiring within the

control cabinet.

• Input filters are configured for a

speed that is too fast

Refer to the wiring guidelines in Section 2.3. It is

very important that the control panel is connected

to a good ground and that high voltage wiring is

not run in parallel with low voltage wiring.

Connect the M terminal on the 24 VDC Sensor

Power Supply to ground.

Increase the input filter delay in the system data

block. Refer to Section 5.2.

D

Loading...

Loading...