9.8 Configuring SINAMICS S120 with 802D sl

Commissioning

9-102

SINUMERIK 802D sl Instruction Manual (BA), 05/2005 Edition

6FC5 397-0CP10-1BA0

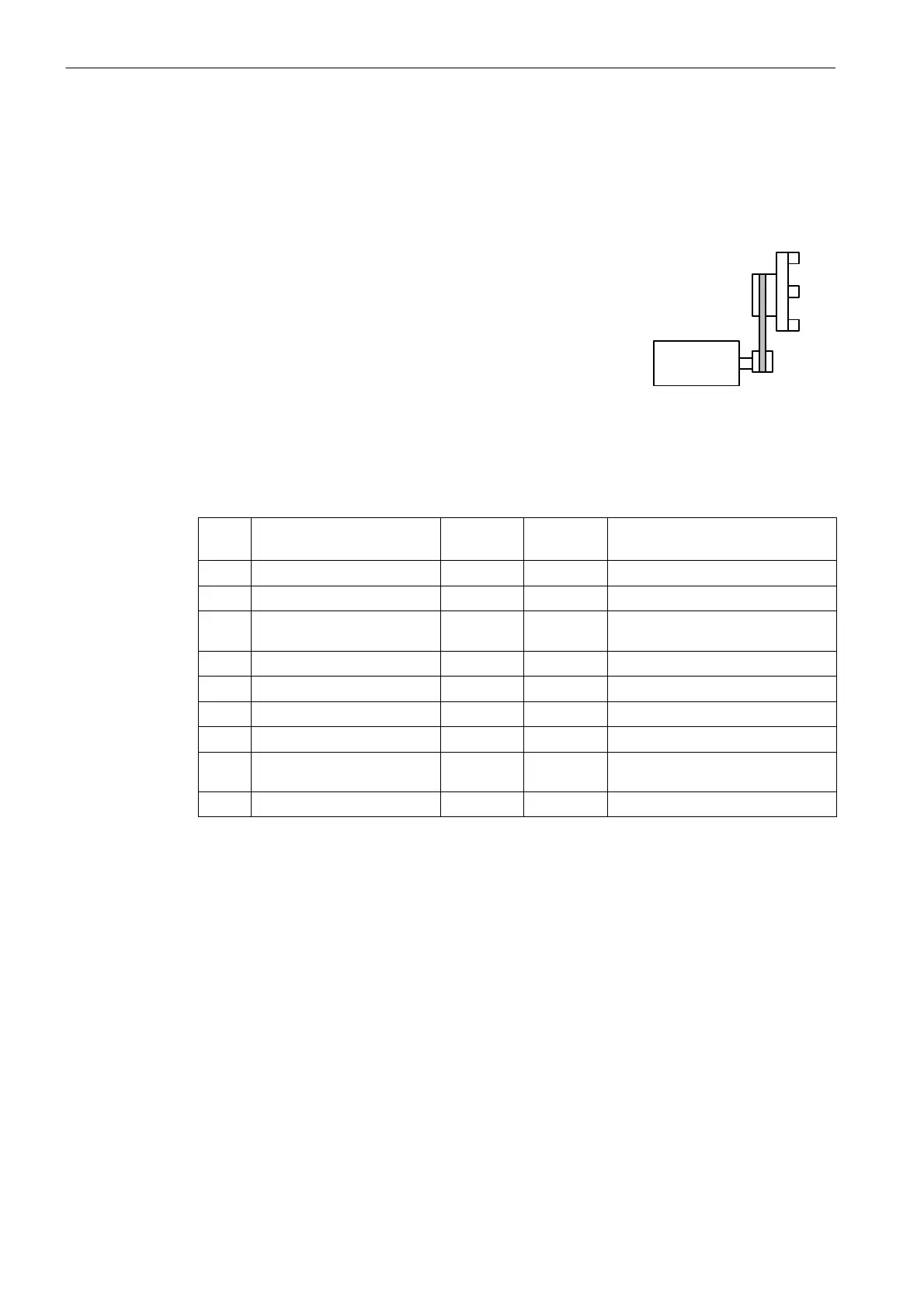

Digital spindle drive with spindle actual-value encoder integrated into the motor

Parameterize the machine data listed in Table 9-8.

Example:

Motor with incremental encoder

Gearbox transmission ratio: 1:2

Max. spindle speed 9,000 r.p.m.

Max. spindle acceleration 60 rev./s

2

Machine data settings:

MD 31030 = 5

MD 31050 = 1

MD 31060 = 2

MD 35130 = 9000

MD 35200 = 60

MD 36200 = 9900

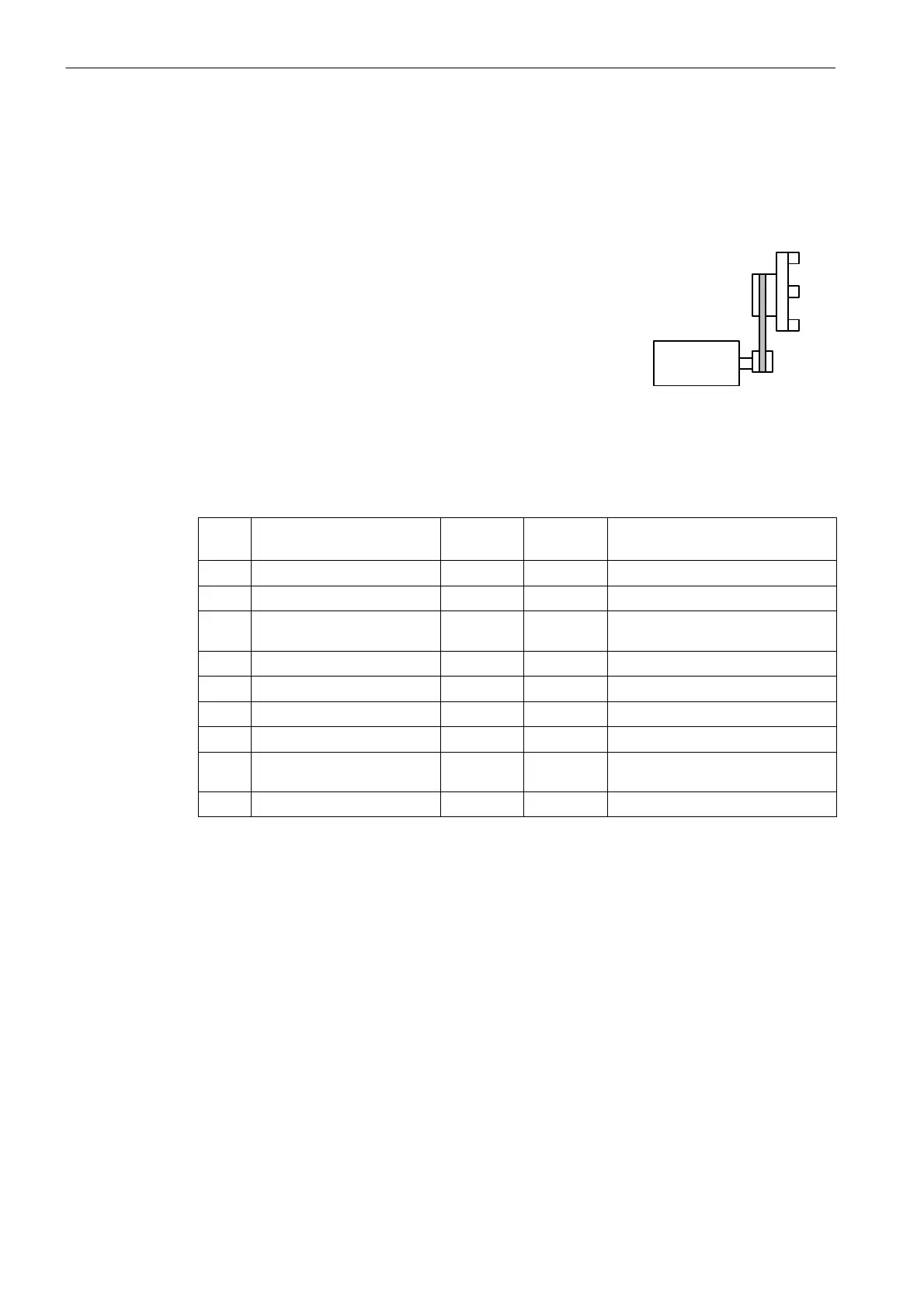

For the spindle, it can be necessary to adapt the following additional machine data.

Table 9-9 Additional machine data

MD

Name Default

value

Unit Recommendation/remark

34000 REFP_CAM_IS_ACTIVE 1 0: without reference point cam

34060 REFP_MAX_MARKER_DIST 20 degrees 720_ = two spindle revolutions

34110 REFP_CYCLE_NR 1 ... 5 0: The spindle is not involved in chan-

nel-specific referencing.

35300 SPIND_POSCTRL_VELO 500 r.p.m.

36000 STOP_LIMIT_COARSE 0,04 degrees 0,4

36010 STOP_LIMIT_FINE 0,01 degrees 0,1

36030 STANDSTILL_POS_TOL 0,2 degrees 1

36060 STANDSTILL_VELO_TOL 0,0139 r.p.m. 1 (interface signal “Axis/spindle

stopped” V390x 0001.4)

36400 CONTOUR_TOL 1 degrees 3

Digital spindle drive with directly mounted spindle actual-value encoder

The operation of a second measuring system requires changes in the message frame type.

To this end, load a reloadable SDB from the toolbox, which allows message frame type 103

for the appropriate drives.

In SINAMICS_I, the message frame type must also be set in P922 = 103.

For the actual-value assignment, the following machine data must be set:

Loading...

Loading...