Commissioning

9.8 Configuring SINAMICS S120 with 802D sl

9-103

SINUMERIK 802D sl Instruction Manual (BA), 05/2005 Edition

6FC5 397-0CP10-1BA0

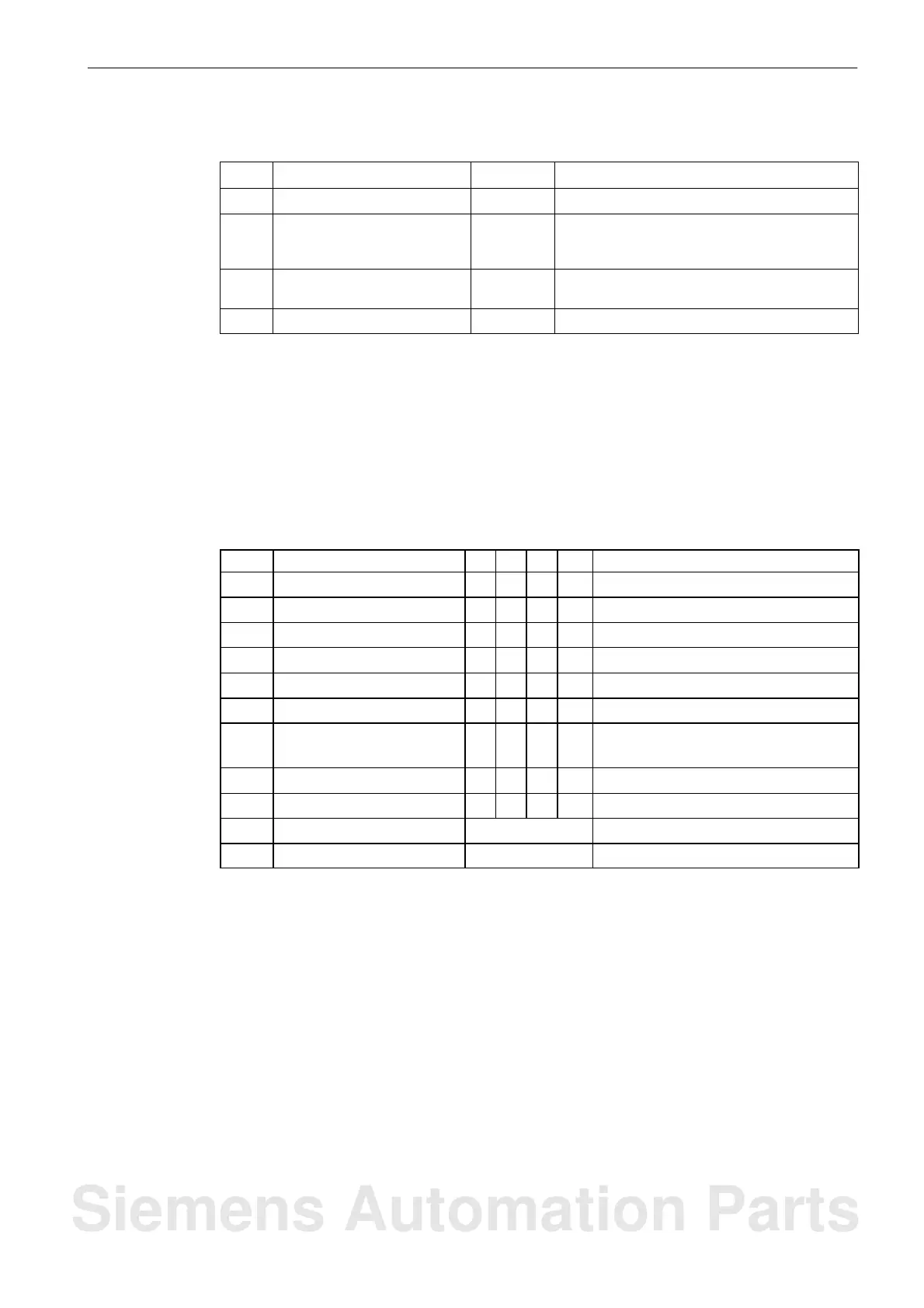

Table 9-10 Machine data to be set

MD

Name Value Recommendation/remark

13060 DRIVE_TELEGRAM_TYPE[0–5] 103

30220 ENC_MODULE_NR[0] 3 Here you must enter a module number to which the

measuring system is connected for the second

measuring system (e.g. “3”).

30230 ENC_INPUT_NR[0] 2 DRIVE-QLIQ_slot on the module to which the second

measuring system has been connected

32110 SENC_FEEDBACK_POL[0] –1 If necessary, swap the counting direction

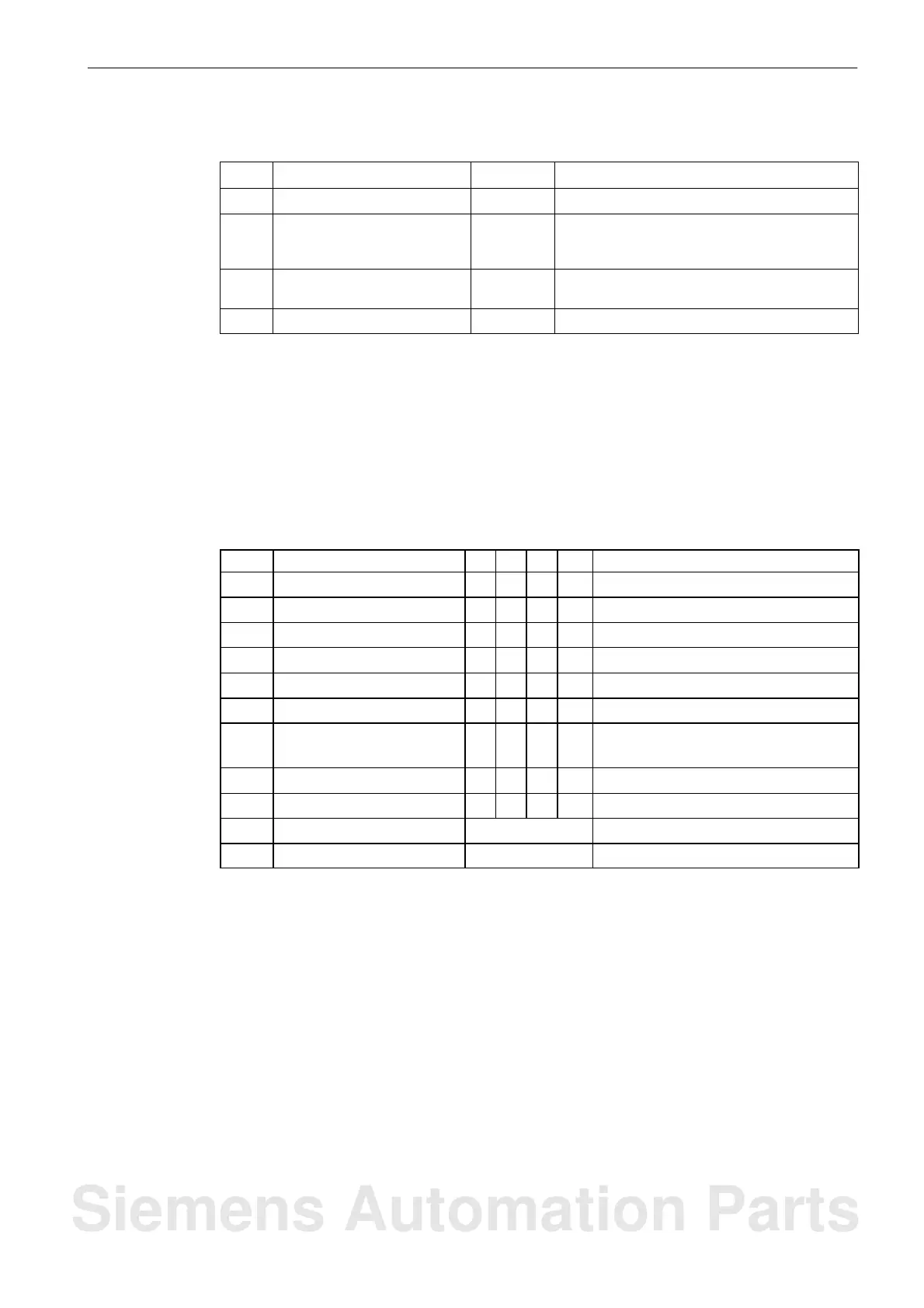

Machine data example for 3 axes for milling with analog spindle

Output of an analog setpoint for a spindle drive for connecting a third-party converter (e. g.

MICROMASTER). With software release 01.01., connection is possible via the MCPA

module.

ALM; 1-axis module; 1-axis module; 1-axis module

Table 9-11 Machine data for the example

MD

Name X Y Z SP Remark

30100 CTRLOUT_SEGMENT_NR 5 5 5 0 local bus segment for analog

30110 CTRLOUT_MODULE_NR 2 3 1 1 Module order

30120 CTRLOUT_NR 1 1 1 1 Setpoint output on drive module/module

30130 CTRLOUT_TYPE 1 1 1 1 Setpoint output type

30134 IS_UNIPOLAR_OUTPUT 0 0 0 0 Setpoint output is unipolar

30200 NUM_ENCS 1 1 1 1 Number of encoders

30220 ENC_MODULE_NR 2 3 1 3 Transport module (the SMC30 module is to be

connected to the axis module of the Y axis

30230 ENC_INPUT_NR 1 1 1 2 Input on the drive module (X202)

30240 ENC_TYPE 4 1 1 1 Encoder type

32250 RATED_OUTVAL (spindle) 80 Rated output voltage 8 V at Umax/min

32260 RATED_VELO (spindle) 3200 Rated motor speed at 8 V

To be able to transfer the encoder actual value, an SDB must be reloaded which reflects the

hardware configuration (see Toolbox 802D_SL\V0100xx00\Special\DMSforSpindle).

Thereafter, set the following machine data:

Siemens Automation Parts

Loading...

Loading...