Machine and Setting Data 802D

A.1 List of machine data

A-207

SINUMERIK 802D sl Instruction Manual (BA), 05/2005 Edition

6FC5 397-0CP10-1BA0

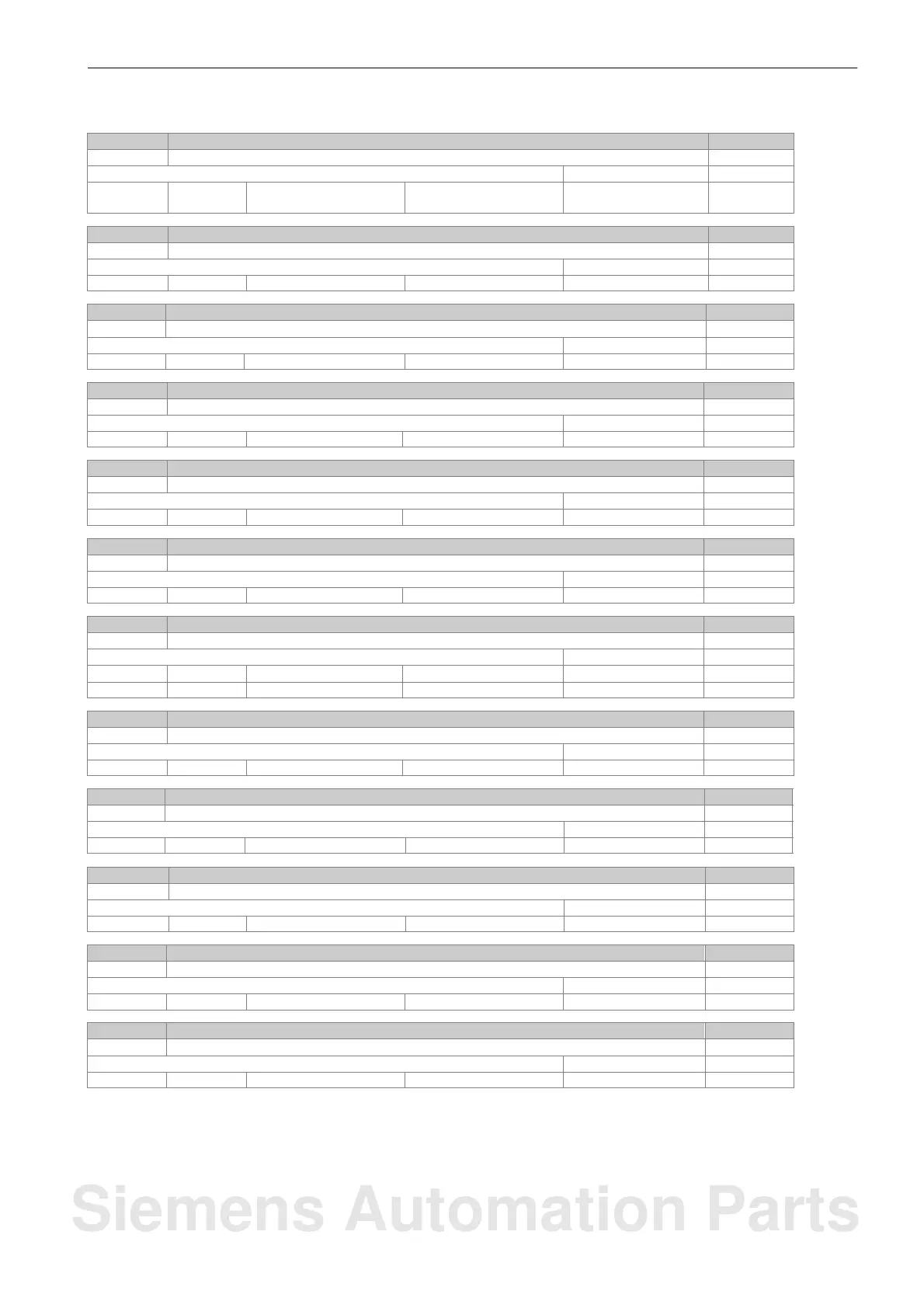

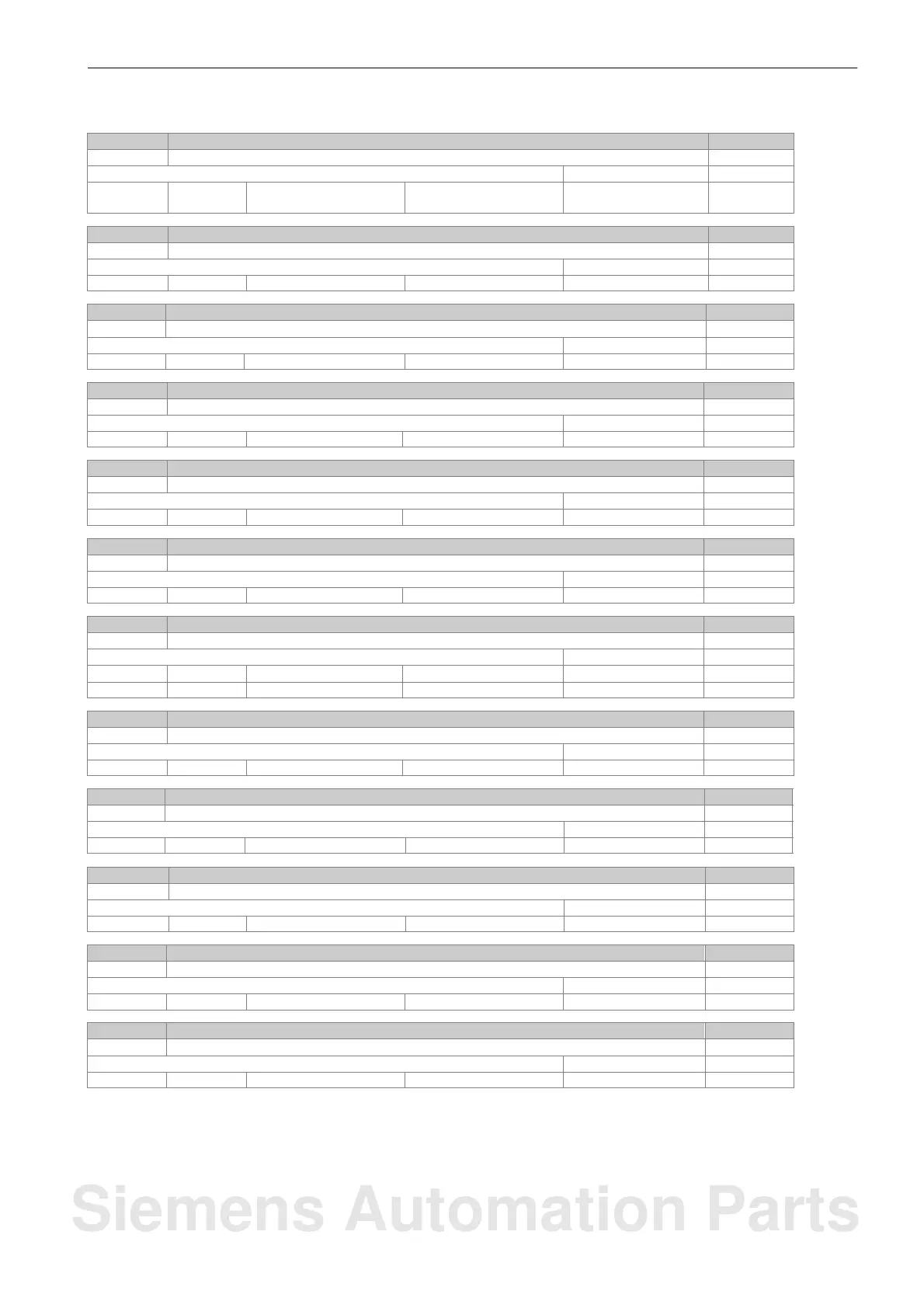

20080 AXCONF_CHANAX_NAME_TAB

– Name of channel axis in the channel POWER ON

C01, C11, C10 – STRING

Default 6 “X”, “Y”, “Z”, “SP”, “A”,

“PLCX”

– – 2/2

20090 SPIND_DEF_MASTER_SPIND

– Number of master spindle POWER ON

C01, C03 – BYTE

Default – 1 1 2 2/2

20094 SPIND_RIGID_TAPPING_M_NR

– M function for axis mode (Siemens mode) POWER ON

C01, C03, C10 – DWORD

Default – 70 – – 2/2

20095 EXTERN_RIGID_TAPPING_M_NR

– M function for axis mode (external mode) POWER ON

C01, C11, C03, C10 – DWORD

Default – 29 – – 2/2

20106 PROG_EVENT_IGN_SINGLEBLOCK

– Prog events ignore single block POWER ON

N01 – DWORD

Default – 0x0 0 0x1F 2/2

20107 PROG_EVENT_IGN_INHIBIT

– Prog events ignore read–in disable POWER ON

N01 – DWORD

Default – 0x0 0 0x1F 2/2

20108 PROG_EVENT_MASK

– Event–controlled program calls POWER ON

N01 – DWORD

Default – 0x0 0 0xF 7/2

plus – – – – 2/2

20140 TRAFO_RESET_VALUE

– Active transformation in case of RESET RESET

C03 – BYTE

Default – 0 0 2 2/2

20204 WAB_CLEARANCE_TOLERANCE

mm Direction reversal with SAR POWER ON

C06 – DOUBLE

Default – 0.01 – – 2/2

20310 TOOL_MANAGEMENT_MASK

– Activate tool management functions POWER ON

C09 – DWORD

Default – 0x0 0 0xFFFFFFF 2/2

20320 TOOL_TIME_MONITOR_MASK

– Time monitoring for the tool in the toolholder POWER ON

C06, C09 – DWORD

Default – 0x1 – – 2/2

20360 TOOL_PARAMETER_DEF_MASK

– Definition of the tool parameters POWER ON

C09 – DWORD

Default – 0x0 0 0xFFFF 2/2

Siemens Automation Parts

Loading...

Loading...