Machine and Setting Data 802D

A.1 List of machine data

A-225

SINUMERIK 802D sl Instruction Manual (BA), 05/2005 Edition

6FC5 397-0CP10-1BA0

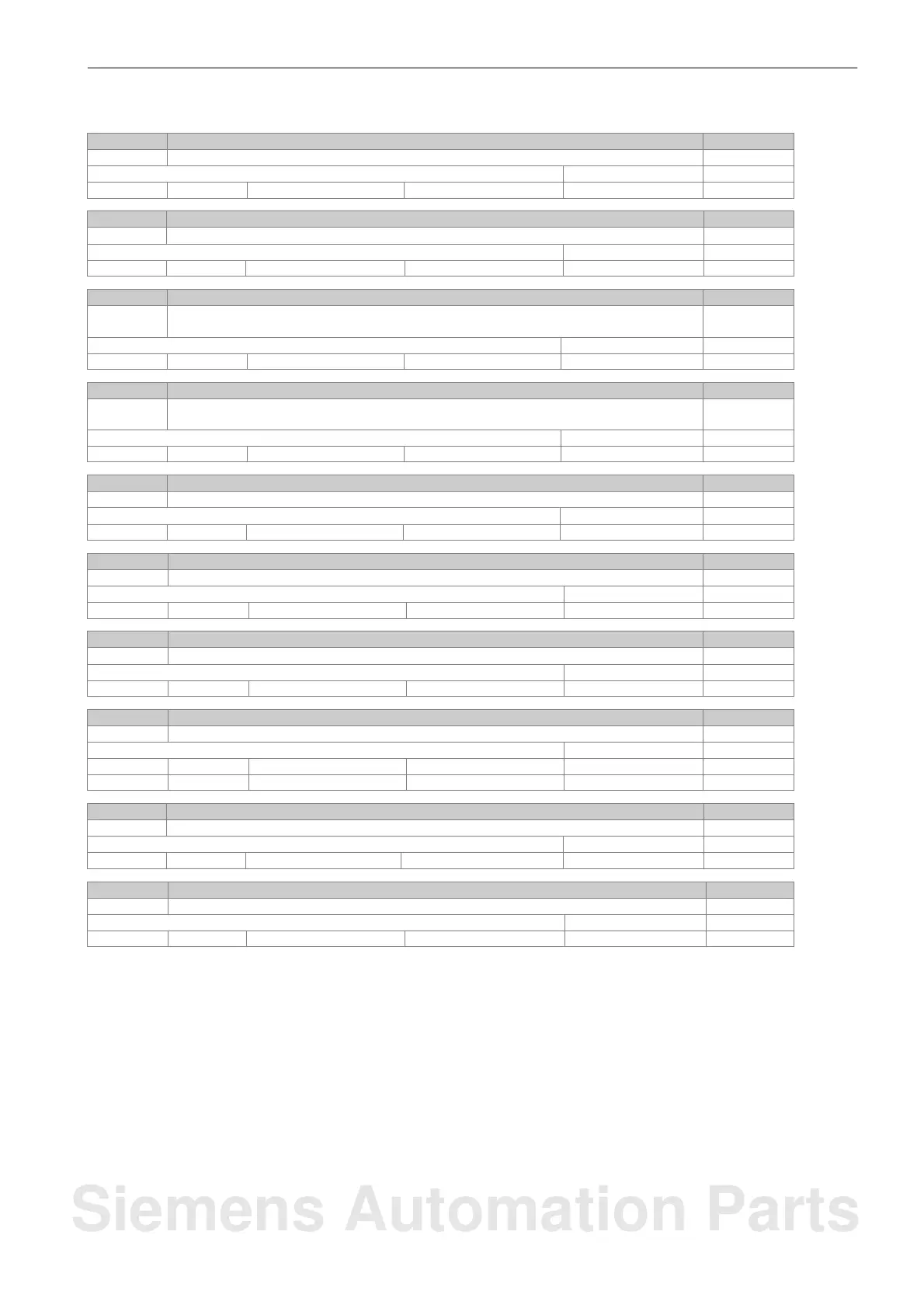

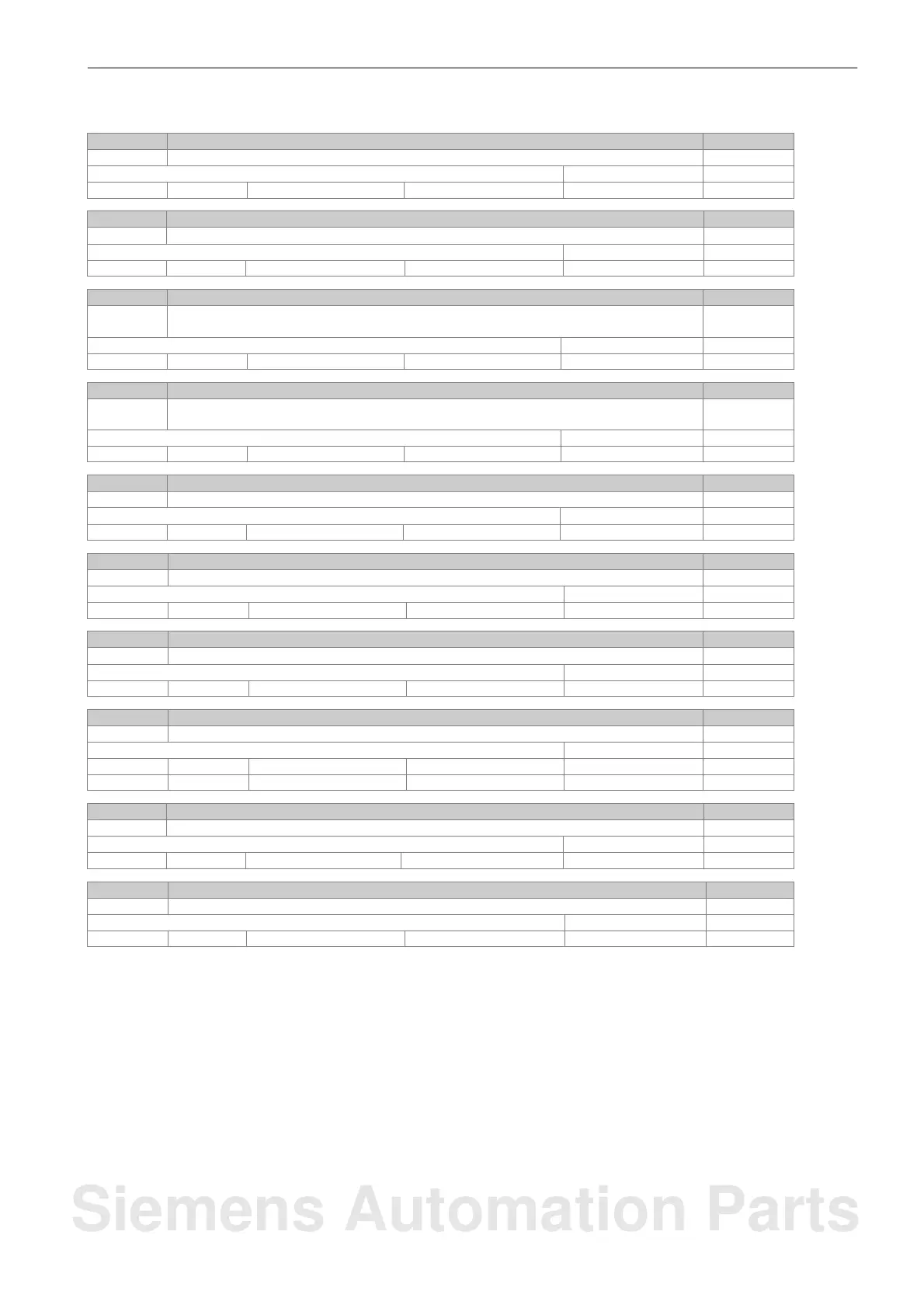

37012 FIXED_STOP_TORQUE_RAMP_TIME

s Time until the changed torque limit is reached NEW CONF

– – DOUBLE

Default – 0.0 – – 2/2

37014 FIXED_STOP_TORQUE_FACTOR

– Torque limit adaptation factor NEW CONF

– – DOUBLE

Default – 1.0 – – 2/2

37020 FIXED_STOP_WINDOW_DEF

mm,

degrees

Fixed stop monitoring window default setting POWER ON

–, – CTEQ DOUBLE

Default – 1.0 – – 2/2

37030 FIXED_STOP_THRESHOLD

mm,

degrees

Threshold for fixed stop detection NEW CONF

– – DOUBLE

Default – 2.0 – – 2/2

37040 FIXED_STOP_BY_SENSOR

– Fixed stop detection via sensor IMMED.

– CTEQ BYTE

Default – 0 0 3 2/2

37050 FIXED_STOP_ALARM_MASK

– Enabling of the fixed–stop alarms NEW CONF

–, – – BYTE

Default – 1 0 15 2/2

37060 FIXED_STOP_ACKN_MASK

– Masking of PLC acknowledgments POWER ON

– CTEQ BYTE

Default – 0 0 3 2/2

37610 PROFIBUS_CTRL_CONFIG

– Profibus control bit configuration POWER ON

EXP, – – BYTE

Default – 0 0 2 7/2

plus – – – – 2/2

37620 PROFIBUS_TORQUE_RED_RESOL

% Resolution of Profibus torque reduction NEW CONF

EXP, – – DOUBLE

Default – 1.0 0.01 10.0 2/2

38000 MM_ENC_COMP_MAX_POINTS

– Intermediate points for encoder/spindle compensation POWER ON

–, –, – – DWORD

Default 1 125 0 5000 7/0

Siemens Automation Parts

Loading...

Loading...