Section 06 DRIVE SYSTEM

Subsection 01 (DRIVE BELT)

DRIVE BELT

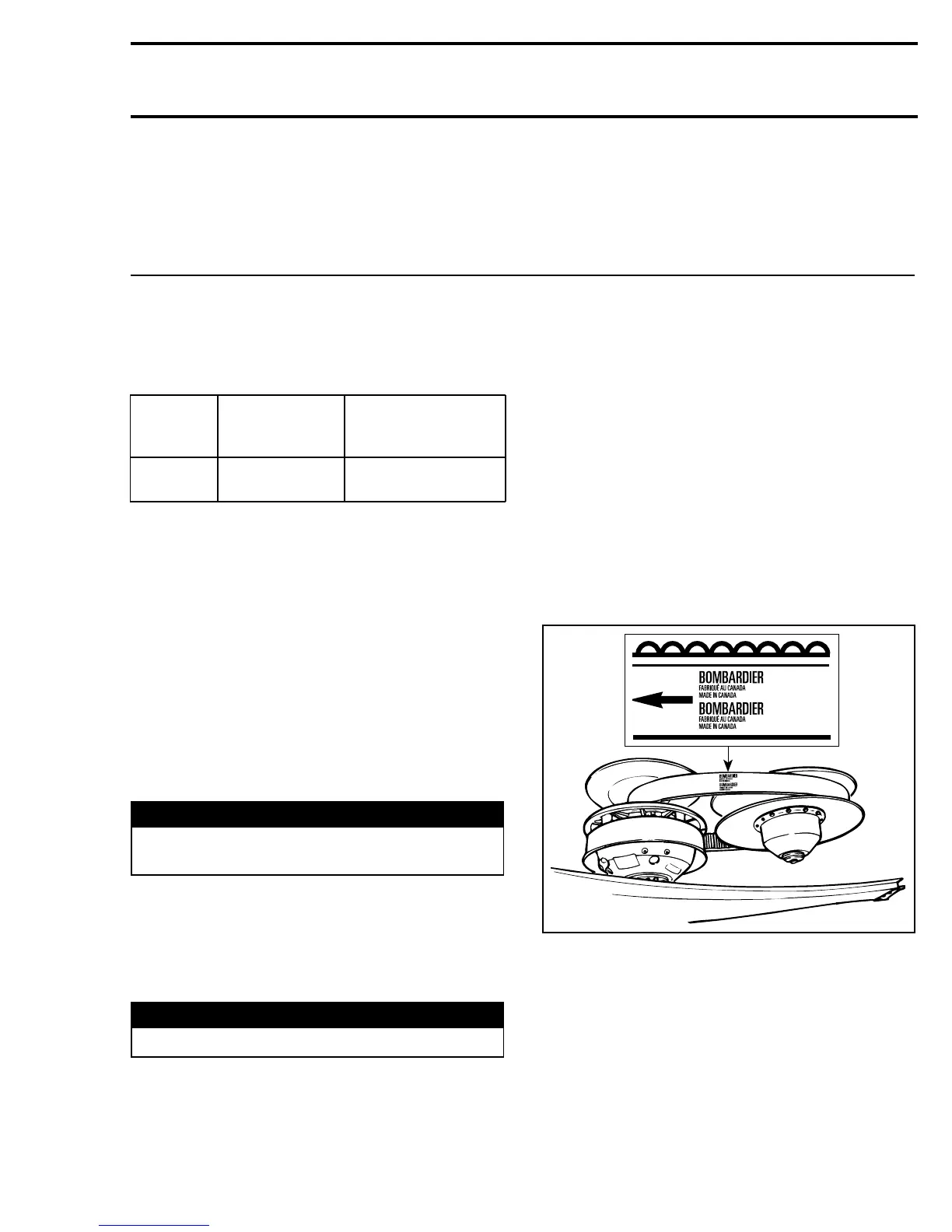

SERVICE TOOLS

Description Part Number Page

belt tension tester ................................................................ 414 348 200 ......................................... 187

APPLICATION CHART

MODEL PART NUMBER

MINIMUM WIDTH

(wear limit)

mm (in)

995 SDI

engines

417 300 189 35.9 (1.413)

INSPECTION

Inspect belt for cracks, fraying or abnormal wear

(uneven wear, wear on one side, missing cogs,

cracked fabric). If abnormal wear is noted, prob-

able cause could be pulley misalignment, exces-

sive RPM with frozen track, fast starts without

warm-up period, burred or rusty sheave, oil on belt

or distorted spare belt.

Check drive belt width. Replace the drive belt

if width is under minimum recommended width

(see table above).

CHECKING NEUTRAL FUNCTION

WARNING

Always check neutral function when servic-

ing.

Apply parking brake. Vehicle must be on the

ground and on a plane level surface. No one

should be in front of vehicle.

Attach vehicle tether cord to your clothing. Stand

aside of vehicle, then start engine.

WARNING

Do not sit on vehicle.

Release parking brake. Vehicle must not creep

when engine is idling. Otherwise, make sure that:

– idle speed is as specified

– proper belt is installed

– pulley center-to-center is as specified

– belt deflection is as specified.

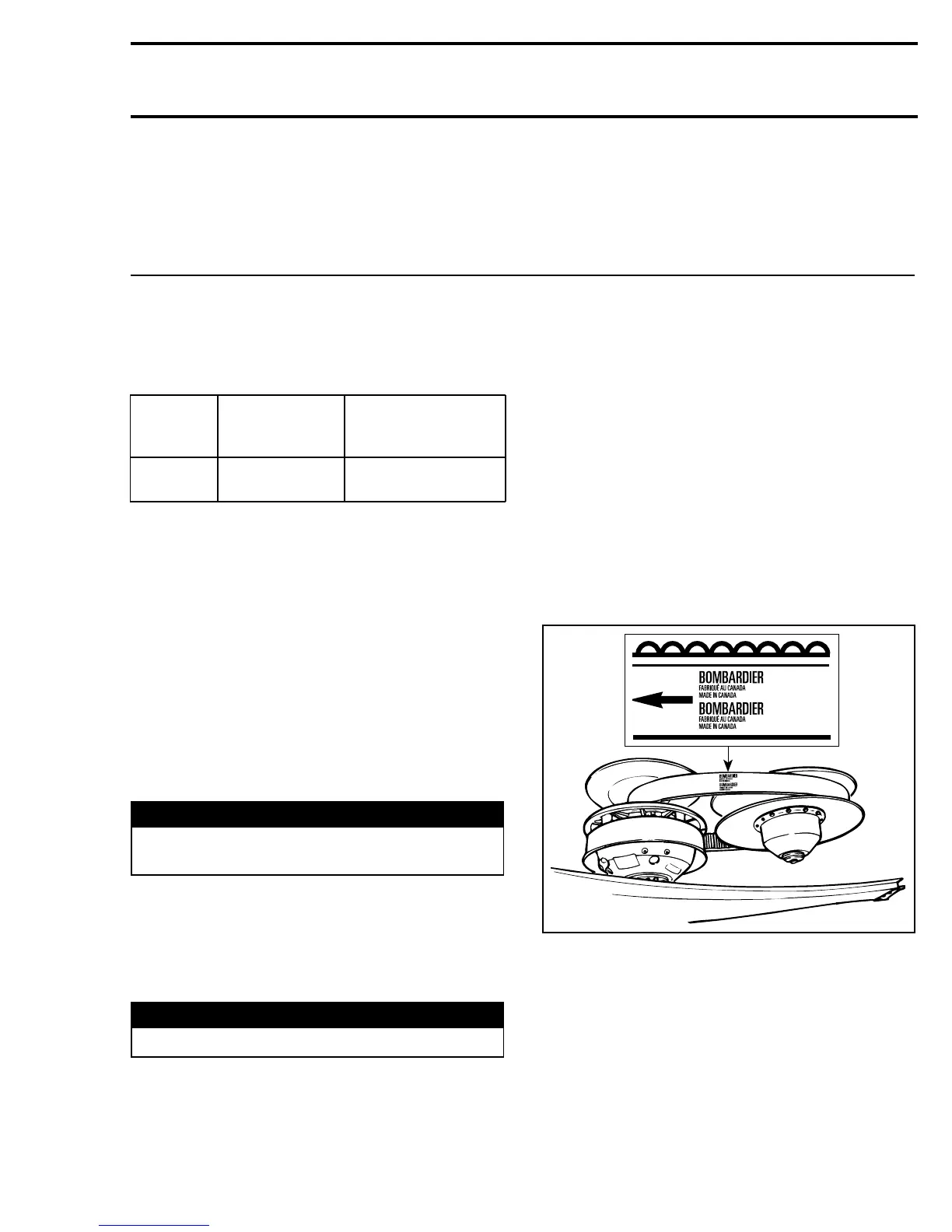

ROTATION DIRECTION

The maximum drive belt life span is obtained

when the drive belt is installed as shown. This

will ensure that correct direction of rotation is

respected.

A01D2KA

CORRECT

mmr2005-131 185

Loading...

Loading...