Section 06 DRIVE SYSTEM

Subsection 02 (DRIVE PULLEY)

GENERAL

WARNING

Never use any type of impact wrench at drive

pulley removal and installation. The use of

impact wrench could damage the drive pulley

and modify the calibration.

Some drive pulley components (return spring,

ramp) can be changed to improve vehicle perfor-

mance in high altitude regions. A service bulletin

will give information about calibration according

to altitude.

CAUTION: Such modifications should only be

performed by experienced mechanics since

they can greatly affect vehicle performance.

Verify spring specifications before installation.

Do not only refer to the spring color code.

NOTE: TRA drive pulley stands for Total Range

Adjustable drive pulley.

WARNING

Any drive pulley repairs must be performed

by an authorized Ski-Doo dealer. Subcompo-

nent installation and assembly tolerances re-

quire strict adherence to procedures detailed.

Ring Gear

Each time the drive pulley is removed from the

engine, check the tightening of ring gear screws.

Torque them if necessary.

CAUTION: All 995 engines are equipped with

a ring gear, even though the vehicle does not

have an electric starter. The ring gear is used

as a damper. Do not remove it.

REMOVAL

Remove drive belt.

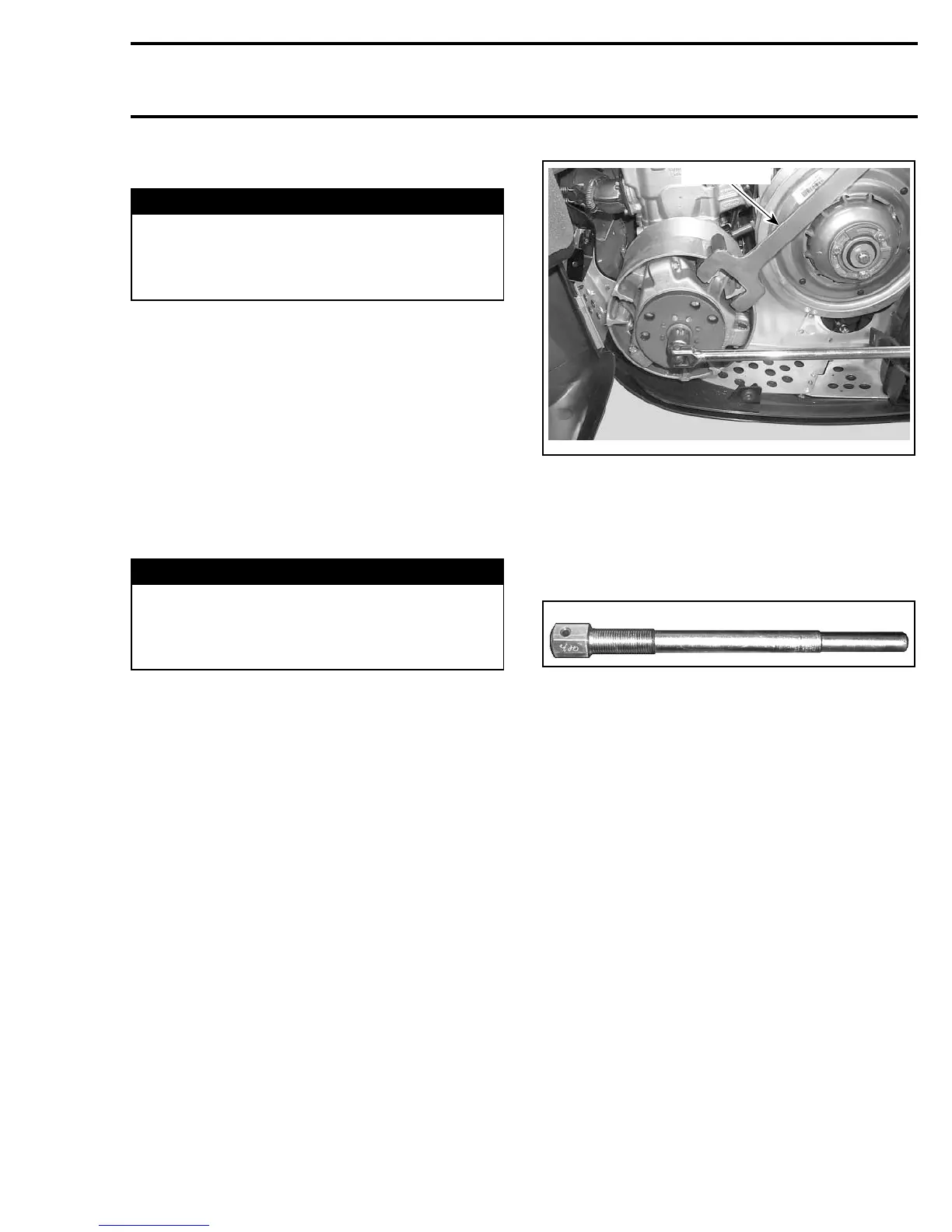

Secure drive pulley no. 1 with the drive pulley

holder (P/N 529 035 674). Install it over a sliding

half tower.

A32D1WC

529 035 674

TYPICAL — INSERT THE TOOL IN SLIDING FLANGE TOWER

Remove the drive pulley bolt no. 2 and its conical

spring washer no. 3.

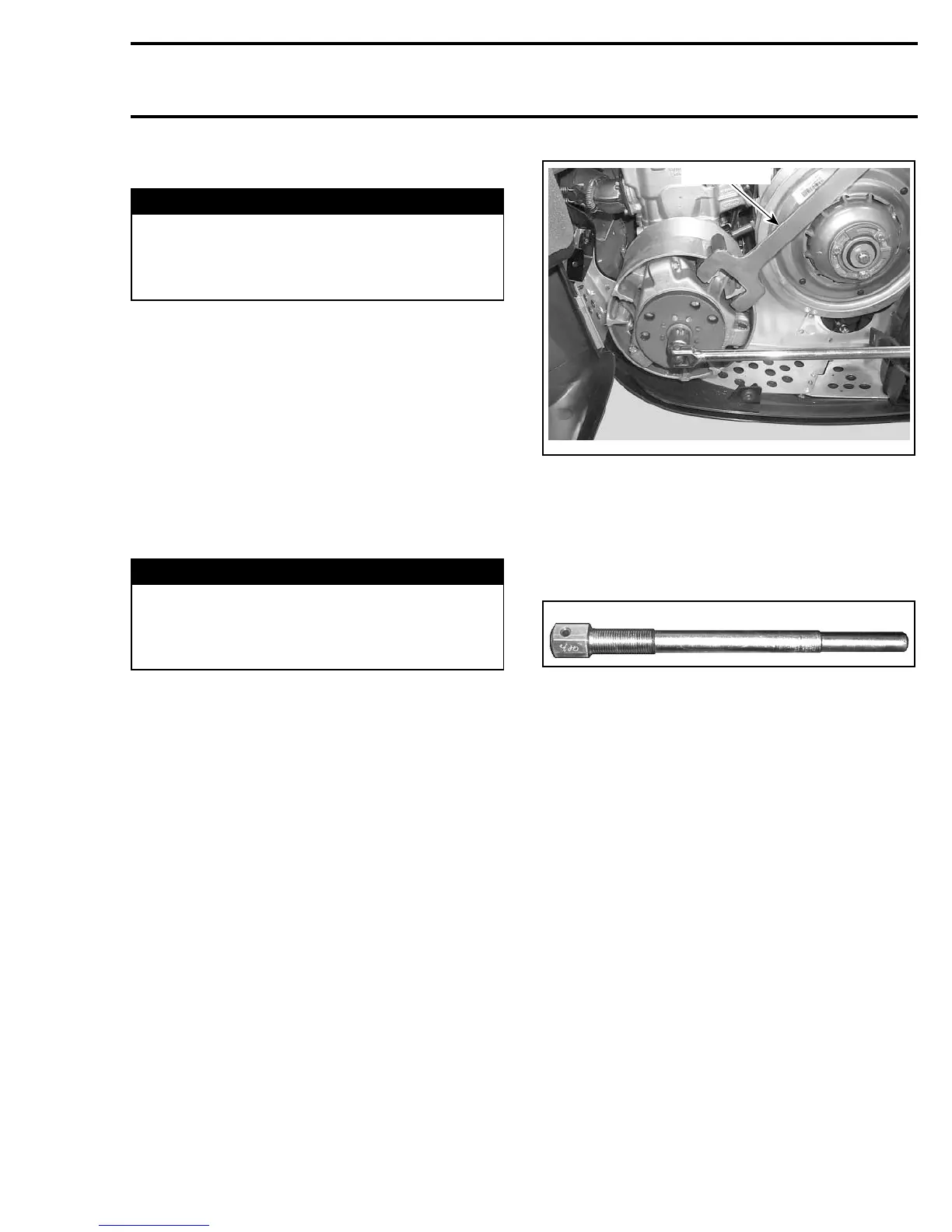

To remove drive pulley no. 1 and/or fixed half no. 4

from engine, use the drive pulley puller (P/N 529

022 400).

529 022 400

Retain drive pulley with the drive pulley holder

(P/N 529 035 674), and install the puller in pulley

shaft then tighten.

CAUTION: These pulleys have metric threads.

Do not use imperial threads puller. Always

tighten puller by hand to ensure that the drive

pulleyhasthesametypeofthreads(metricvs

imperial) prior to fully tightening.

DISASSEMBLY

Ring Gear

To remove the ring gear no. 5, use a heat gun to

break the threadlocker on ring gear screws no. 6

before disassembly.

CAUTION: If another tool than a heat gun is

used, do not exceed 150°C(300°F).

Fixed Half

CAUTION: NEVER tap on governor cup no. 7.

mmr2005-132 191

Loading...

Loading...