Section02ENGINE

Subsection 08 (BOTTOM END)

CAUTION: Do not use Loctite Primer N with

the Loctite 5910. Do not use Dreibond to

seal crankcase. Using these products or non

silicone-based sealant over a previously sealed

crankcase with Loctite 5910 will lead to poor

adhesion and possibly a leaking crankcase.

These products are chemically incompatibles.

Even after cleaning, these products would

leave incompatible microscopic particles.

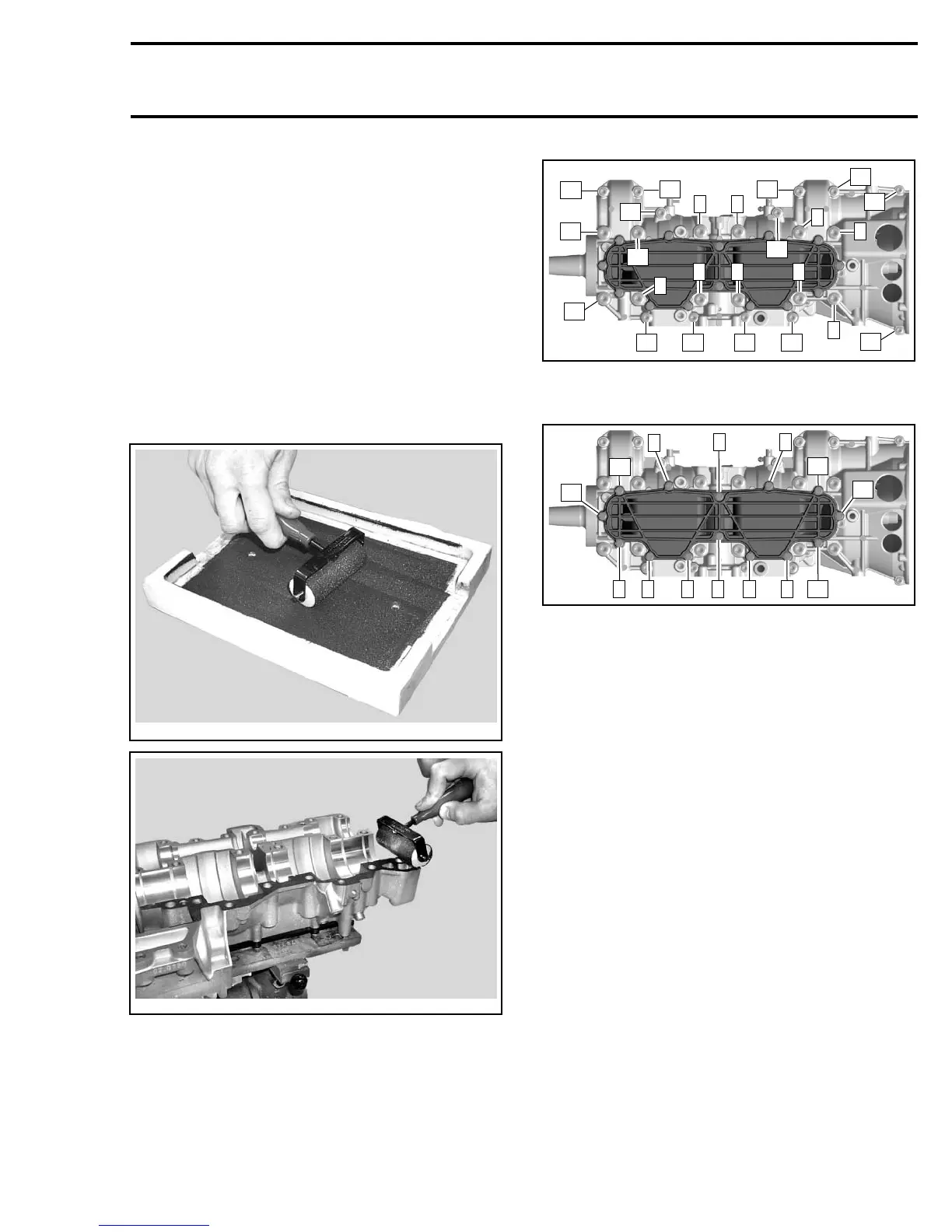

Use a plexiglass plate and apply some sealant on

it. Use a soft rubber roller (50 - 75 mm (2 - 3 in))

(available in arts products suppliers for printmak-

ing) and roll the sealant to get a thin uniform coat

on the plate (spread as necessary). When ready,

apply the sealant on crankcase mating surfaces.

F12R17A

F12R18A

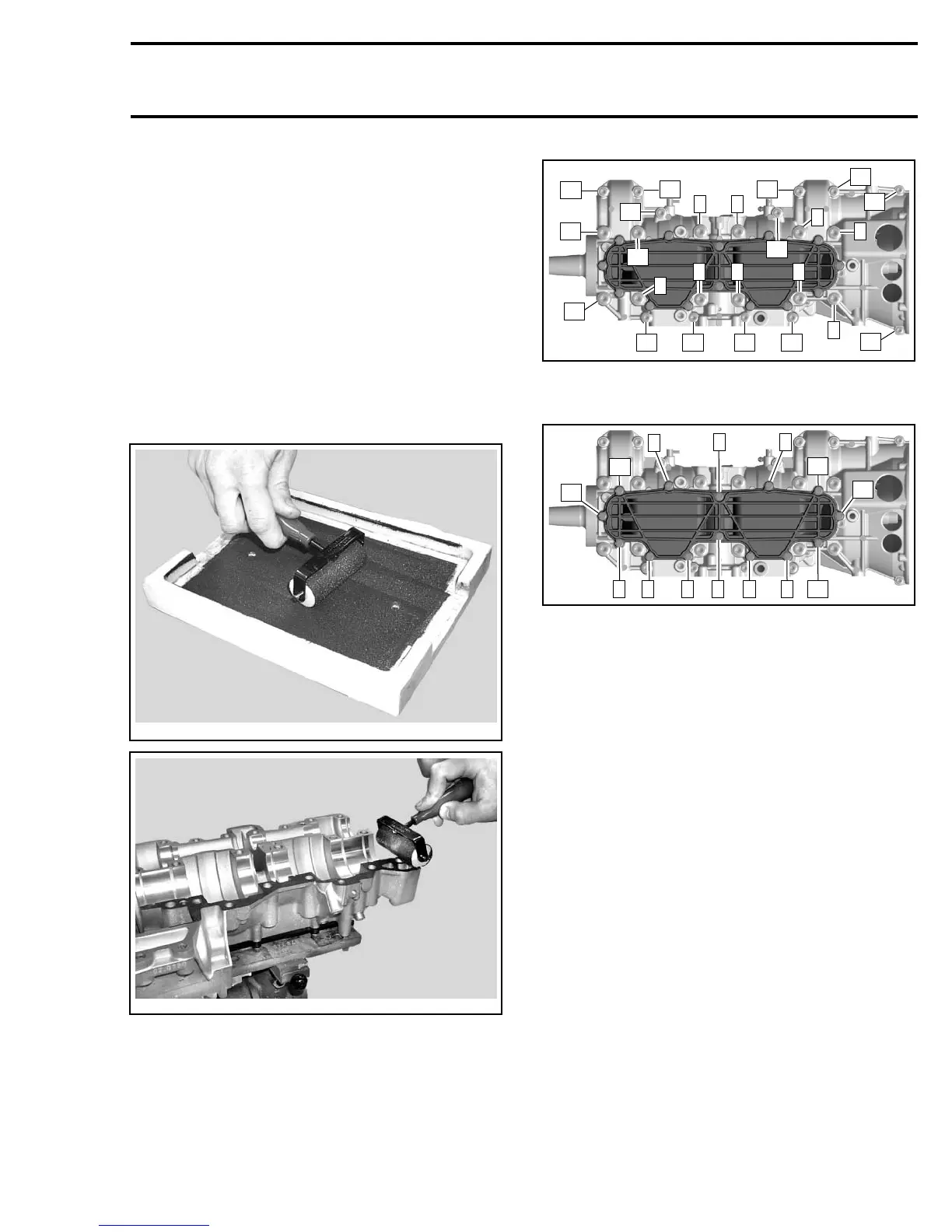

Torque crankcase screws in the following se-

quence. Initially torque M10 screws half the final

torque then, tighten all screws to the required

torque.

A35C1OB

22

21

19

10

9

14

17

6

24

20 18 13

3 1

15

5

7

8

23

12

11

2 4

16

Torque heat exchanger cover screws no. 19 fol-

lowing this sequence.

A35C1OA

10

9

11

5

3

2

4

7

13

1286

14

1

Ensure snap ring no. 2 is properly installed in

crankcase.

BREAK-IN

After rebuilding an engine, always observe a

break-in period as described in Operator’s Guide.

mmr2005-118 73

Loading...

Loading...