Section 06 DRIVE SYSTEM

Subsection 03 (DRIVEN PULLEY)

GENERAL

During assembly/installation, use the torque val-

ues and the service products as in the exploded

views.

Clean threads before applying a threadlocker. Re-

fer to SELF-LOCKING FASTENERS and LOCTITE

APPLICATION at the beginning of this manual for

complete procedure.

WARNING

Torque wrench tightening specifications

must strictly be adhered to.

Locking devices (e.g.: locking tabs, elastic

stop nuts, self-locking fasteners, cotter pins,

etc.) must be installed or replaced with new

ones where specified. If the efficiency of

a locking device is impaired, it must be re-

newed.

WARNING

Never start engine when the pulley guard is

removed.

WARNING

The driven pulley is a precisely balanced unit.

Never replace parts with used parts from an-

other driven pulley.

REMOVAL

Driven Pulley

Remove belt guard and drive belt.

Remove driven pulley bolt no. 1 and shouldered

washer no. 2 then pull the driven pulley no. 3 from

the countershaft.

Countershaft and Countershaft Bearing

To remove and install countershaft and its bearing

refer to CHAINCASE.

DISASSEMBLY

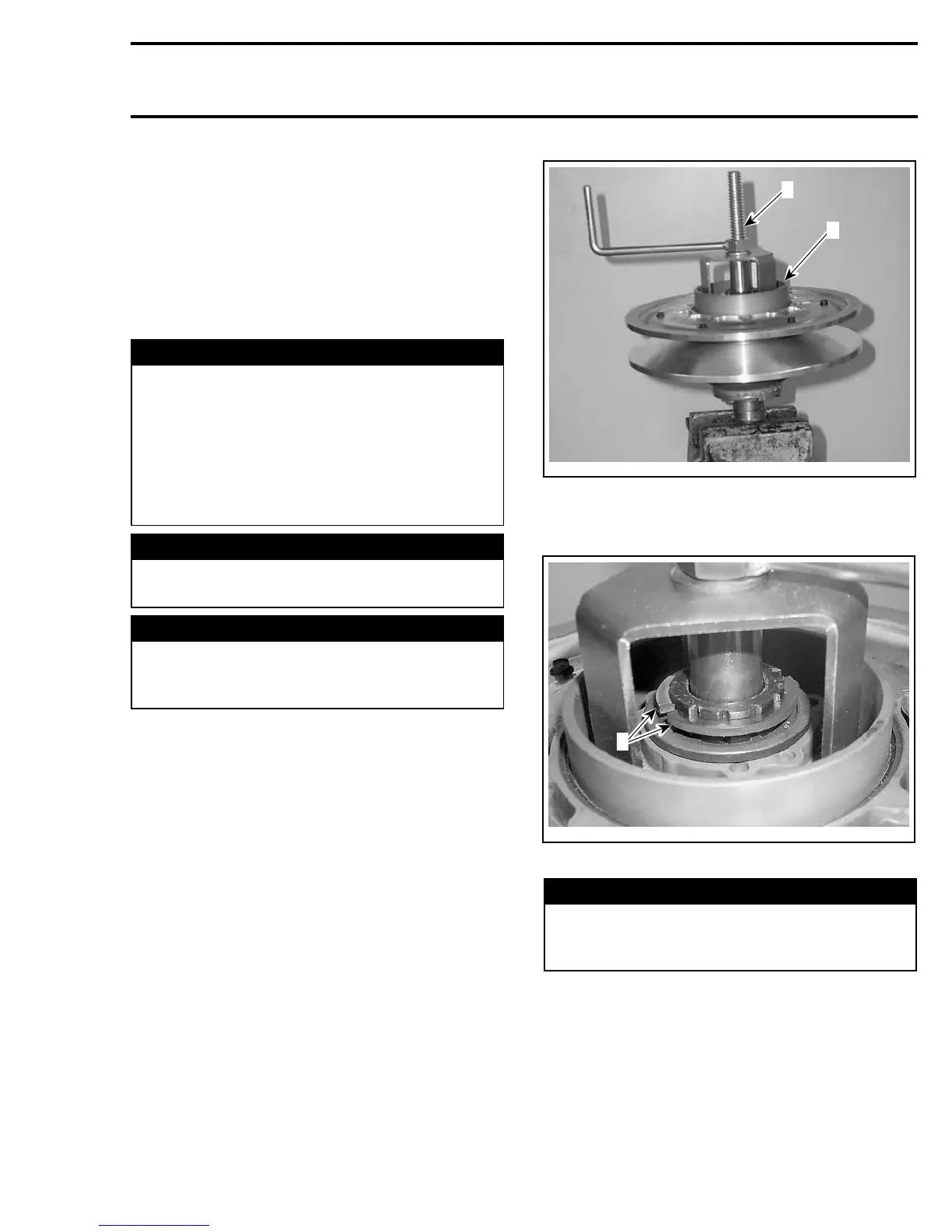

Using the clutch spring compressor (P/N 529 036

012), push the cam no. 4.

A35D11A

2

1

1. Clutch spring compressor

2. Cam

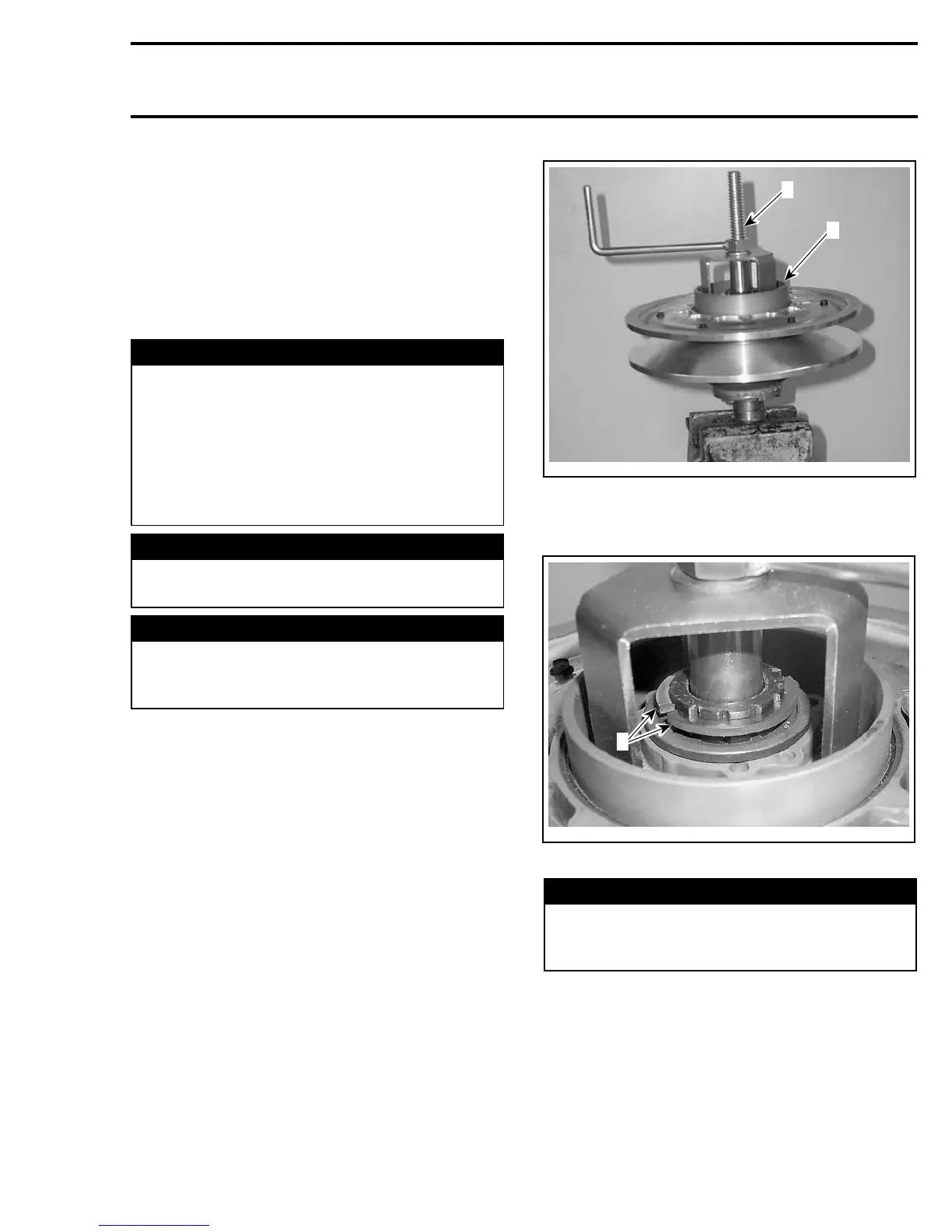

Remove the half keys no. 5.

A35D12A

1

1. Half keys

WARNING

Driven pulley cam is spring loaded, use only

the above mentioned tool. Do not use other

clutch spring compressor.

Unscrew clutch spring compressor then remove

cam and spring no. 6 andseparatethe2pulley

halves.

Remove the circlip no. 9 and the washer no. 10

then remove the roller no. 7 from the roller axle

no. 11.

mmr2005-133 203

Loading...

Loading...