Section02ENGINE

Subsection 09 (ENGINE MEASUREMENT)

A35C30A

A

1

1. Measuring perpendicularly (90°)topistonpinaxis

A. 33 mm (1.3 in)

Read the measurement on the cylinder bore

gauge. The result is the exact piston/cylinder

wall clearance. If clearance exceeds specified

tolerance, replace cylinder or rebore and install

oversize piston depending on engine.

NOTE: Make sure the cylinder bore gauge indica-

tor is set exactly at the same position as with the

micrometer, otherwise the reading will be false.

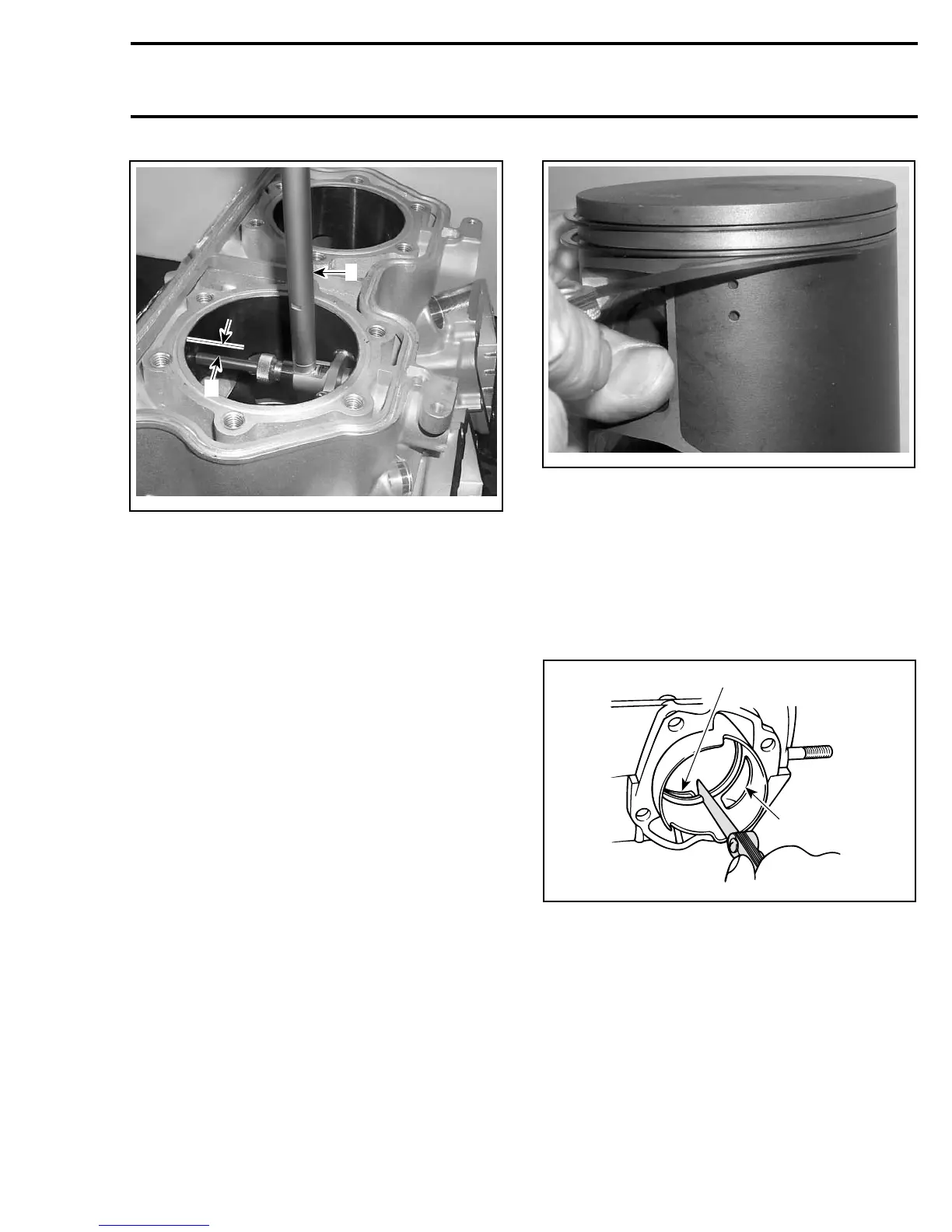

RING/PISTON GROOVE

CLEARANCE

Using a feeler gauge check clearance between

rectangular ring and groove. Replace piston if

clearance exceeds specified tolerance.

A35C31A

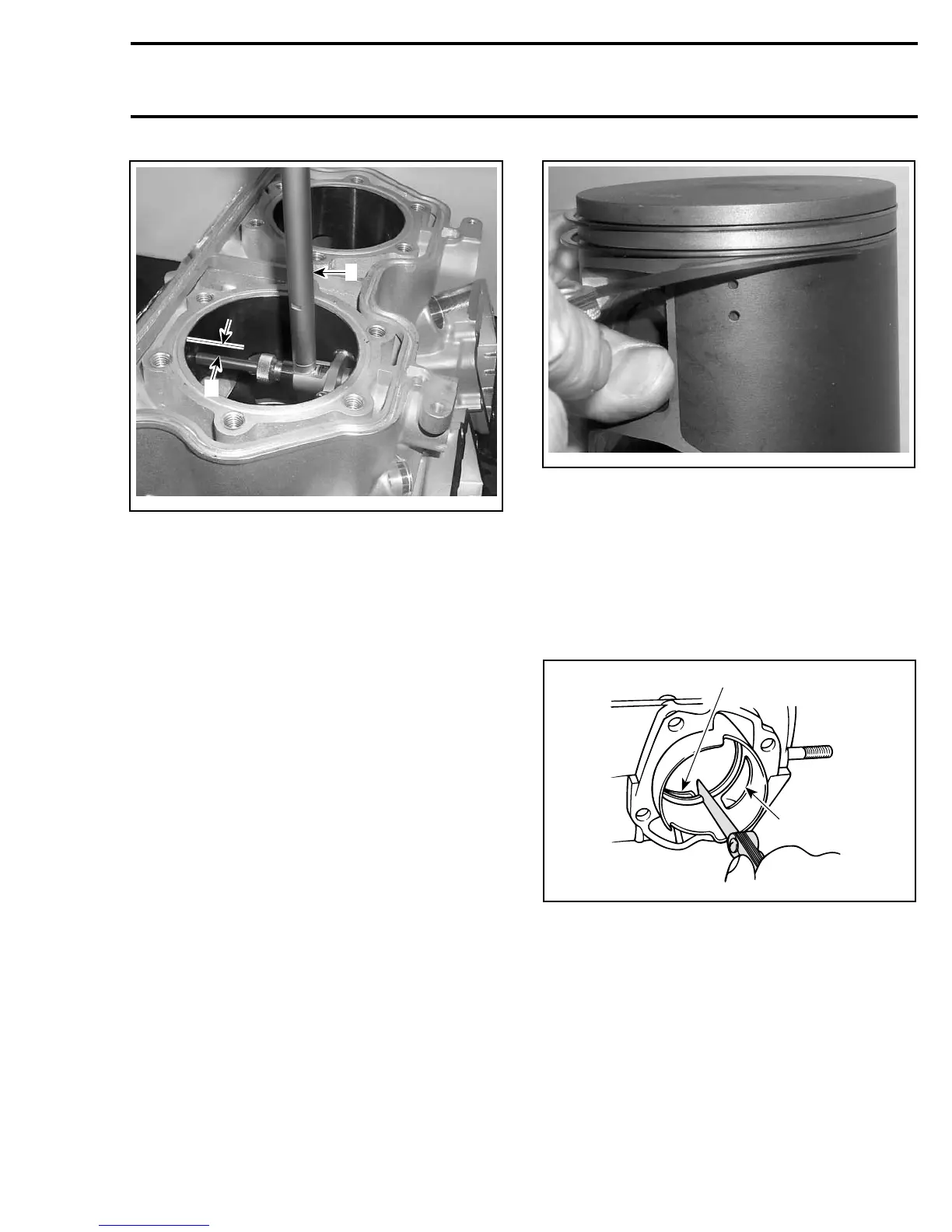

RING END GAP

Position ring halfway between transfer ports and

intake port.

NOTE: In order to correctly position the ring in the

cylinder, use piston as a pusher.

Using a feeler gauge, check ring end gap. Replace

ring if gap exceeds specified tolerance.

A01C0QA

2

1

TYPICAL

1. Transfer port

2. Intake port

CRANKSHAFT DEFLECTION

Crankshaft deflection is measured with a dial indi-

cator.

mmr2005-119 79

Loading...

Loading...