Section 06 DRIVE SYSTEM

Subsection 03 (DRIVEN PULLEY)

A35D17A

Place the large bushing extractor (P/N 529 035

575) below bushing and screw the threaded rod

of the clutch spring compressor (P/N 529 036 012)

in the large bushing extractor hole until the end of

threaded rod reaches against the support plate.

A35D18A

1 2

3

TYPICAL

1. Support plate

2. Large bushing extractor

3. Threaded rod of spring compressor

Mount the clutch spring compressor head in a

vise.

Using a heat gun, heat bushing to break the adhe-

sive product.

Turn pulley half by hand to extract old bushing.

Before bushing installation, clean residues of

adhesive product by using pulley flange cleaner

(P/N 413 711 809).

On threaded rod install both sleeves and one

spacer included with the clutch spring compres-

sor (P/N 529 036 012).

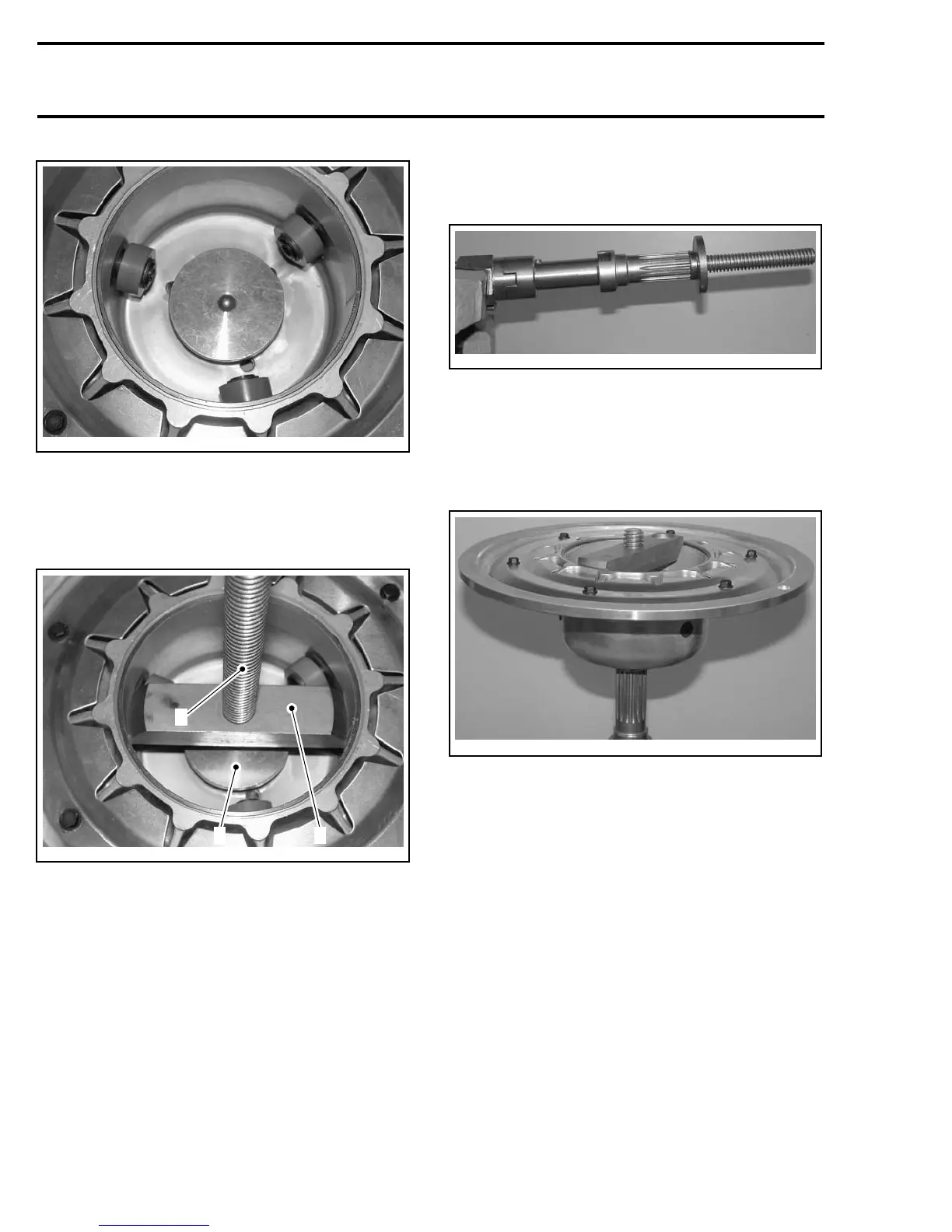

A35D19A

Coat bushing outside diameter with Loctite 380

(Black MAX) (P/N 413 408 300). Place new bush-

ing on sliding half and slightly tap to engage

squarely the bushing in the sliding.

Install the sliding pulley on threaded rod and screw

in the large bushing extractor (P/N 529 035 575).

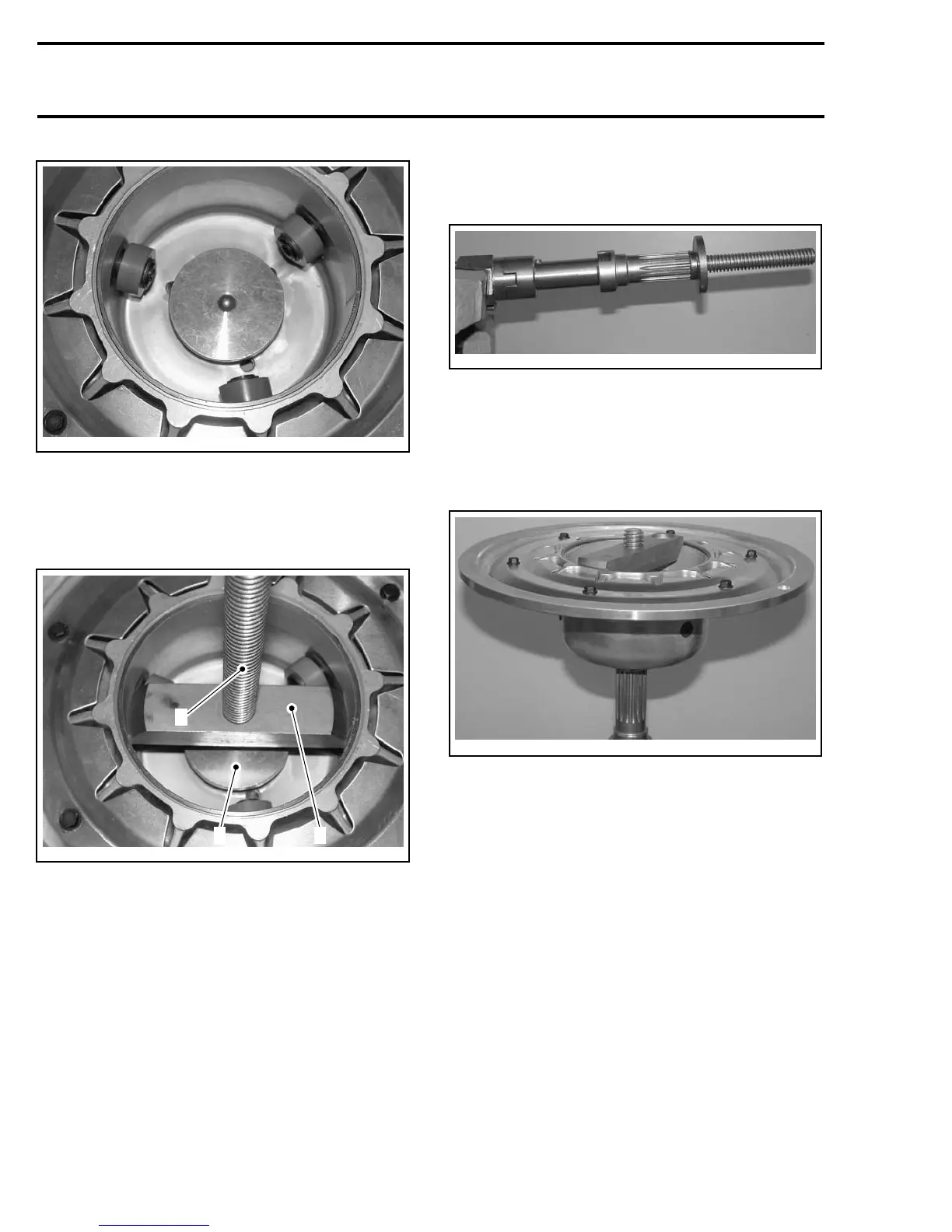

A35D1AA

Turn pulley half by hand to insert the new bushing.

NOTE: Change the position of extractor often to

push the bushing straight.

Install circlip.

Small Bushing

Remove circlip.

Using a press, extract the small bushing. Push

the bushing out of its location by using a pipe with

proper diameter.

Clean residues of adhesive product by using pulley

flange cleaner (P/N 413 711 809).

Coat bushing outside diameter with Loctite 380

(Black MAX) (P/N 413 408 300).

Using press, bushing extractor/installer (P/N 529

031 300) and the crankshaft protector (P/N 420

876 552), insert small bushing in its location.

206 mmr2005-133

Loading...

Loading...