DC5 User’s Manual

Basic Operation 2-9

Head alignment:

The two above parameters control the alignment in the media direction. There is also a

calibration in the direction of the movement of the head. This is calibrated mechanically

when a head is changed and should not be redone until the head is replaced again.

However due to different media parameters (difference in media roll up tension, thickness

of media) there might also be a need for an extra calibration in the direction of the

movement of the head.

NOTE: If the hard disk is not installed, then this test has to be started from the

program Summa Printer Control.

Automatic head alignment setup:

1. Power on the printer and load the media (see section 1.6.1).

A test pattern is printed. Some printed lines are measured and then internal parameters are

adjusted automatically. If the DC5(sx) has to compensate too much, it will prompt the operator

with following text: “VALUE OUT OF RANGE ALIGN HEAD MECHANICALLY”. In this case a

mechanical calibration, as described in the head change procedure, will need to be redone.

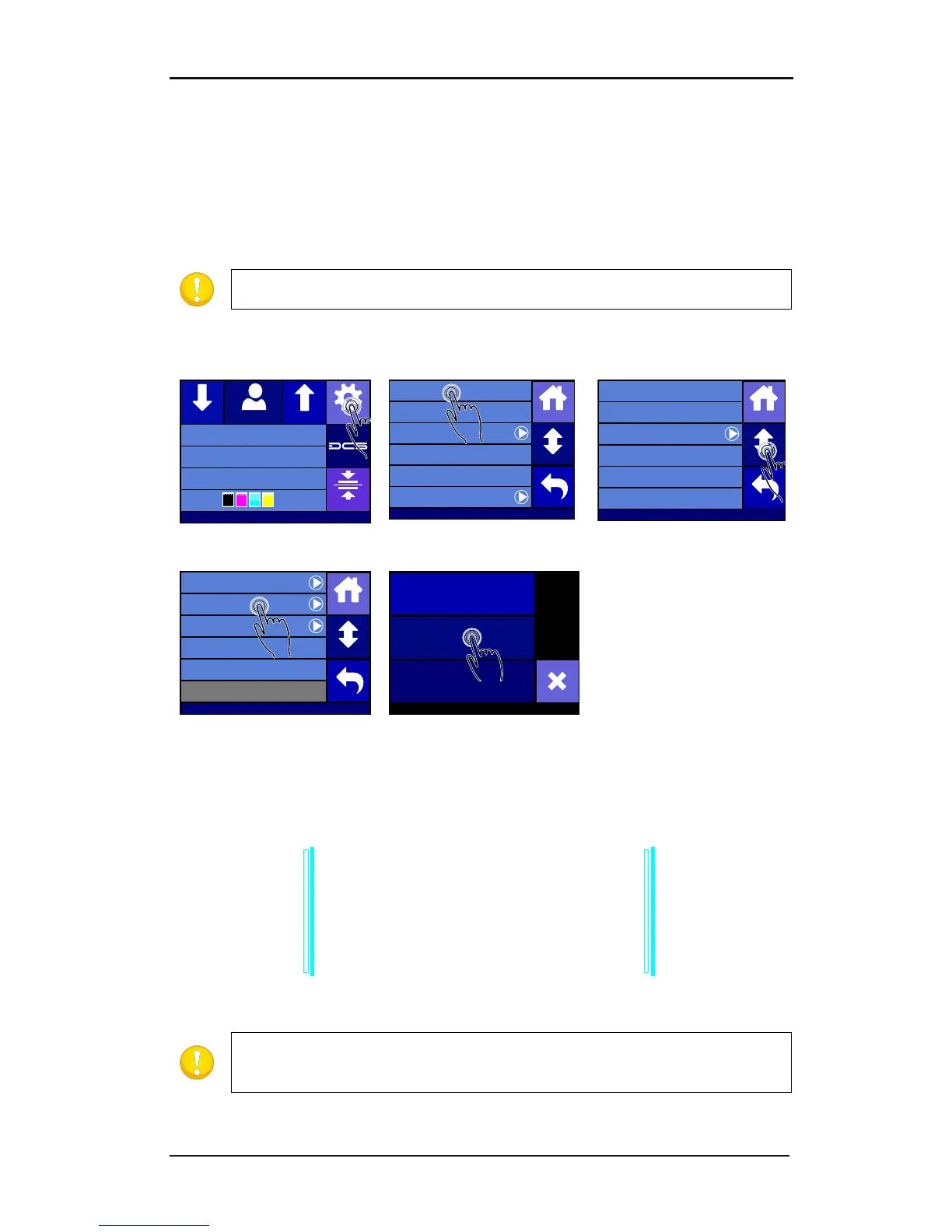

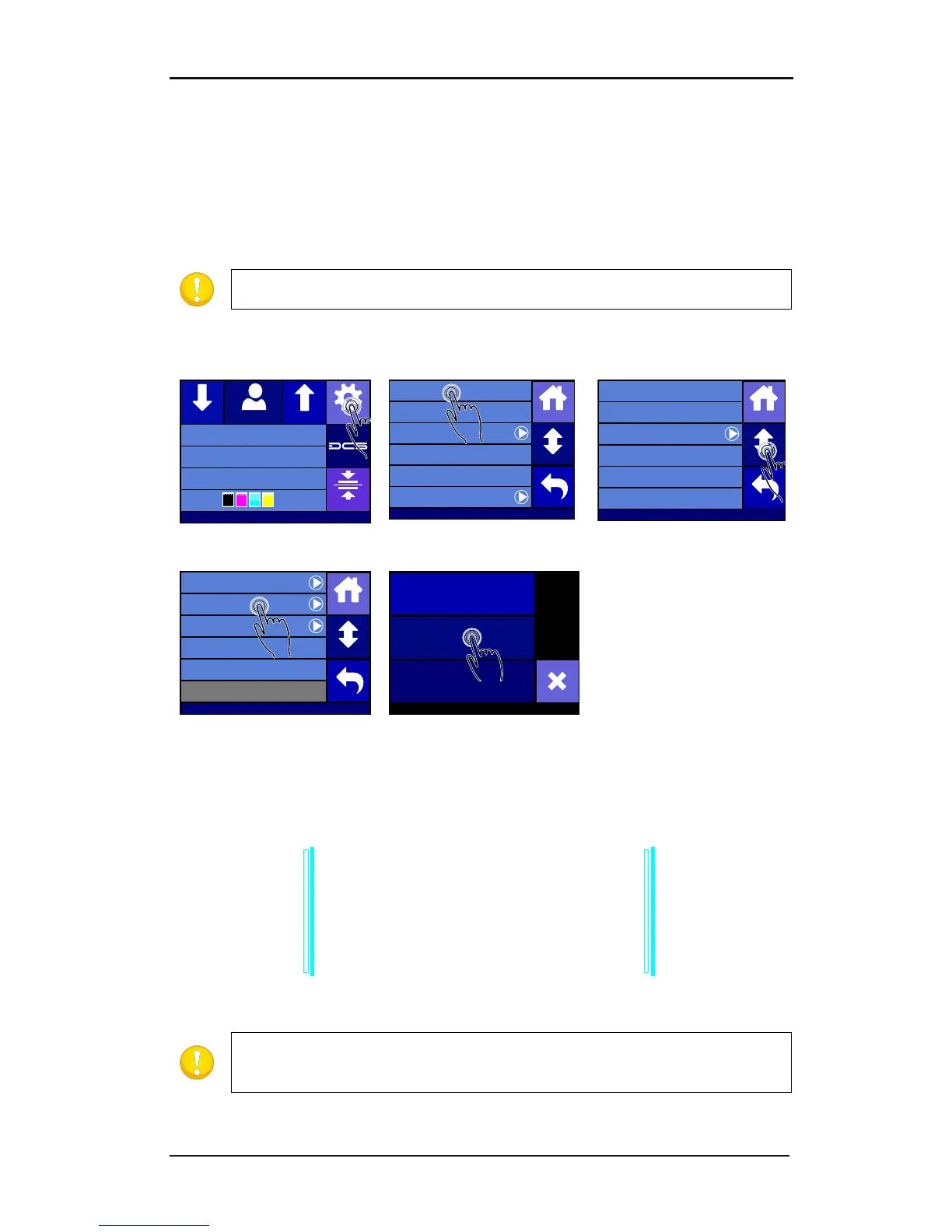

FIG 2-9

2-9 AUTOMATIC HEAD ALIGNMENT TEST

NOTE: Never execute a manual head alignment test after an automatic head

alignment test, because it defaults the automatic head alignment calibration

parameters.

Summa USB port

Density 12000

Knife pressure 75gr

Media width 672mm

Clamp

SettingsFeedConfiguration 1Feed

Settings

Shut down

Communication ...

System menu ...

Reprint job

Cutter menu ...

Printer menu ...

Back

Home

More

Settings | Printer menu

Op tiTr ac Automatic

OptiTrac color Cyan

Scratchguard Off

Calibrate Linefeed

Double Density Off

Density 12000

Back

Home

More

Settings | Printer menu

Color Offset Standard

Dot Overlap On

Clean Printhead

Back

Home

More

Calibrate Print&Cut

Head Alignment

Cancel

MANUAL TEST

AUTOMATIC TEST

Loading...

Loading...