Power Unit Mechanical: 1D-30

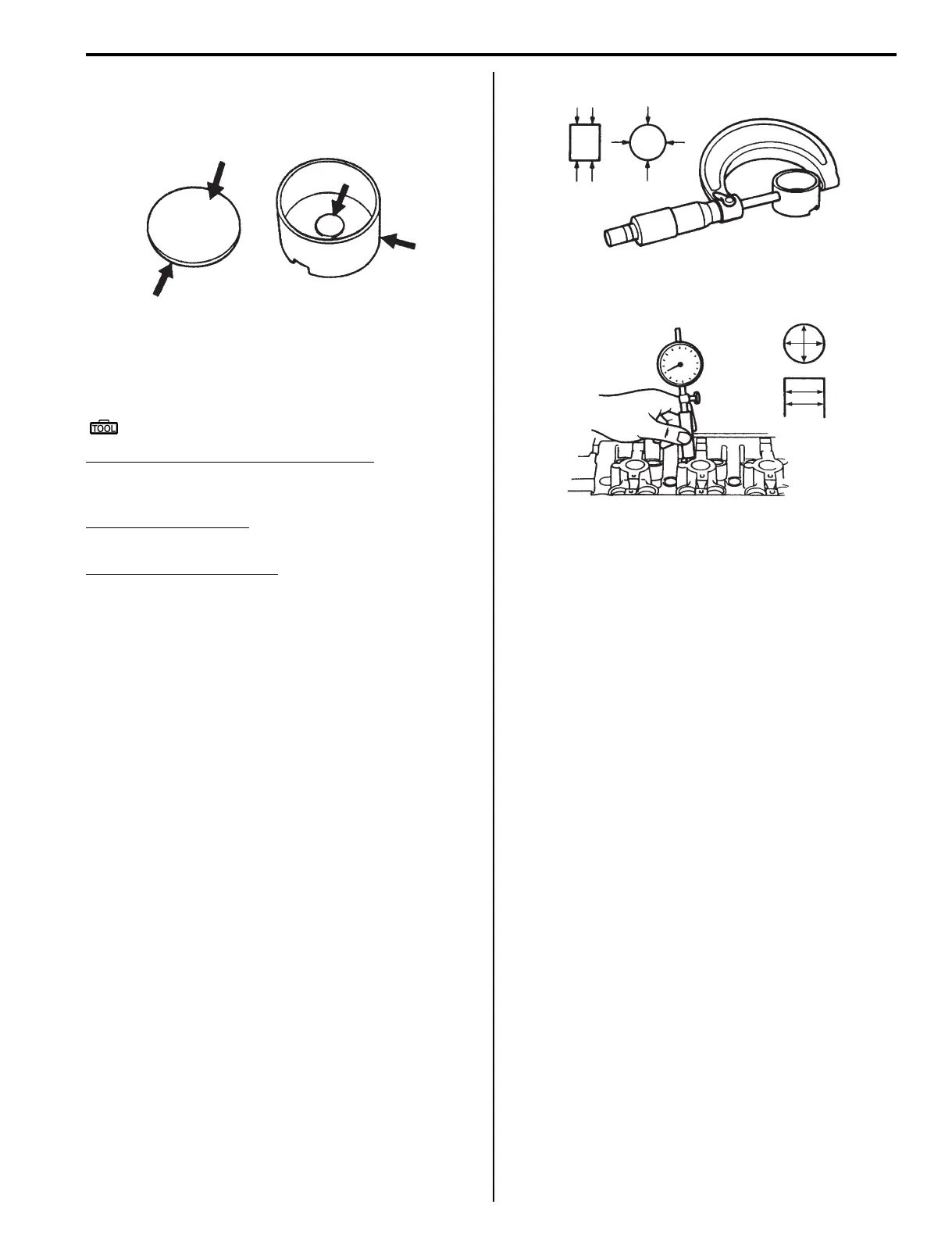

Wear of Tappet and Shim

Check tappet and shim for pitting, scratches, or damage.

If any above conditions are found, replace component.

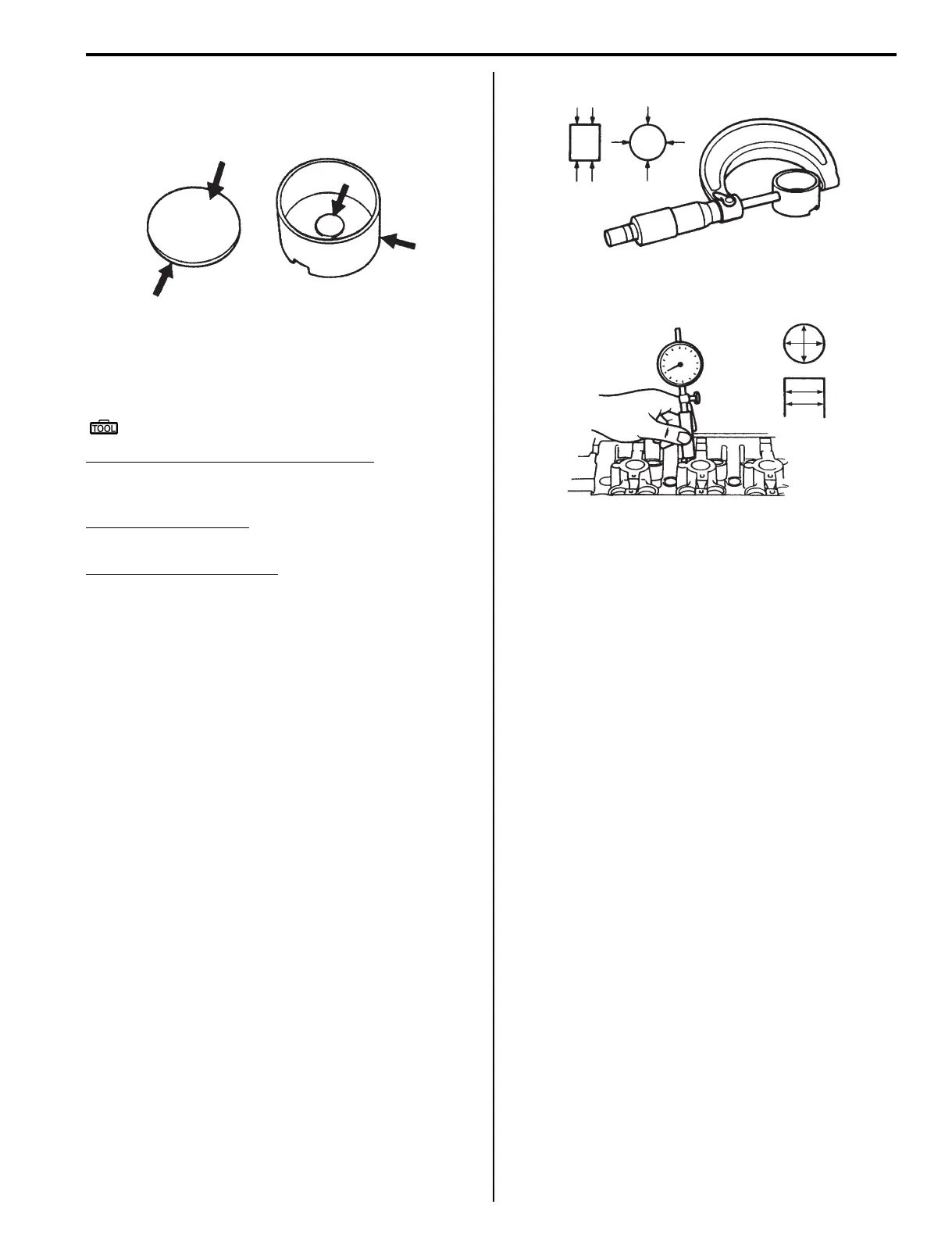

Measure cylinder head bore and tappet outside diameter

to determine cylinder head to tappet clearance.

If clearance exceeds service limit, replace tappet or

cylinder head.

Special tool

: 09900–20202 (Micrometer (25 – 50 mm))

Cylinder head bore to tappet clearance

Standard: 0.025 – 0.062 mm (0.0010 – 0.0024 in.)

Service limit: 0.150 mm (0.0059 in.)

Tappet outer diameter

Standard: 27.959 – 27.975 mm (1.1007 – 1.1014 in.)

Cylinder head tappet bore

Standard: 28.000 – 28.021 mm (1.1024 – 1.1032 in.)

I9J011140076-01

I9J011140031-01

I9J011140032-01

Loading...

Loading...