Power Unit Mechanical: 1D-54

Conrod big end side clearance

Measure conrod big end side clearance with conrod

installed on crank pin as shown.

If measurement exceeds service limit, replace conrod

and/or crankshaft.

Special tool

(A): 09900–20803 (Thickness gauge)

Conrod big end side clearance

Standard: 0.100 – 0.250 mm (0.0039 – 0.0098 in.)

Service limit: 0.35 mm (0.0138 in.)

Conrod big end width

Standard: 21.950 – 22.000 mm (0.8642 – 0.8661 in.)

Crank pin width

Standard: 22.100 – 22.200 mm (0.8071 – 0.8740 in.)

Crank Pin and Conrod Bearing Inspection

Z9J0111406023

Crank Pin Diameter

Inspect crank pin for uneven wear or damage.

Measure crank pin for out-of-round “a” – “b” or taper “c” –

“d” with micrometer.

If crank pin is damaged, out-of-round “a” – “b” or taper

“c” – “d” is out of service limit, replace crankshaft.

Special tool

(A): 09900–20202 (Micrometer (25 – 50 mm))

Crank pin diameter

Standard: 41.982 – 42.000 mm (1.6528 – 1.6535 in.)

Out-of-round and taper

Service limit: 0.01 mm (0.0004 in.)

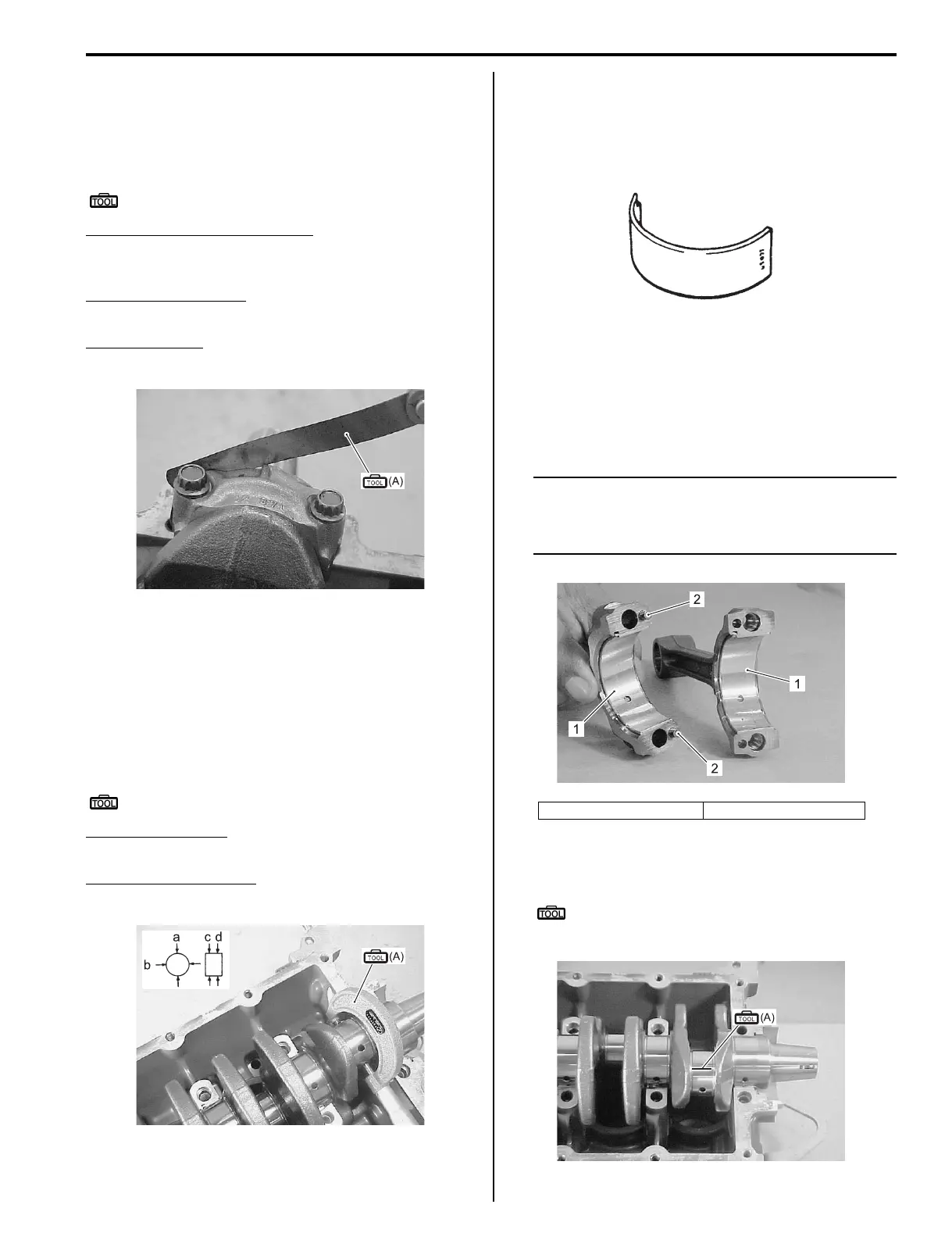

Conrod Bearing Visual Inspection

Inspect bearing shell for proper contact pattern and

signs of fusion, pitting, burning or flaking.

Bearing shells found in defective condition must be

replaced.

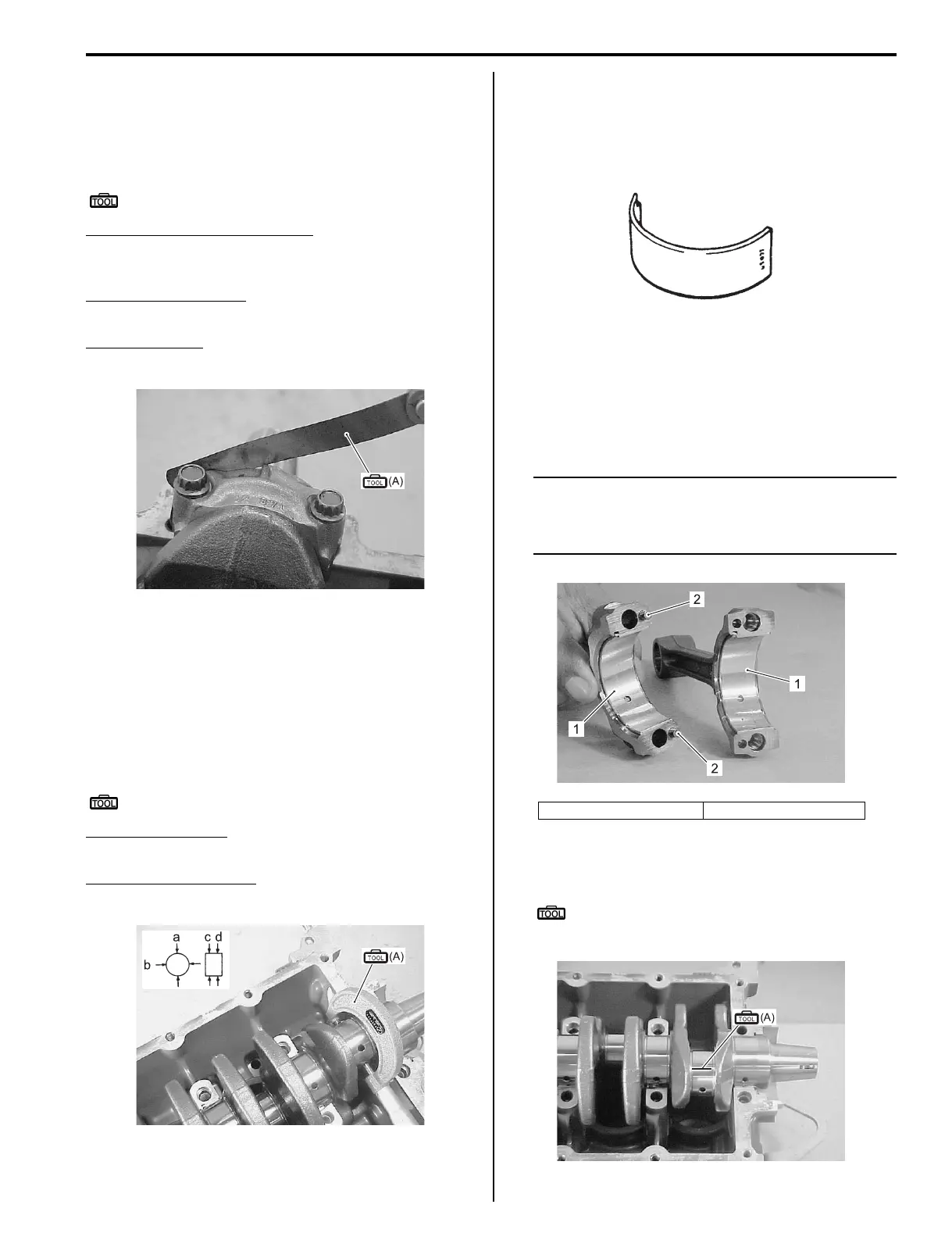

Conrod Big End Oil Clearance

Check conrod big end oil clearance as follows:

1) Clean surface of conrod, conrod cap, conrod

bearing, and crank pin.

2) Install conrod bearing onto conrod and conrod cap.

NOTE

• Reassemble each bearing and conrod cap

to their original position.

• Do not apply oil to bearing.

3) Place a piece of Plastigauge on crank pin parallel to

crankshaft. Avoid placing Plastigauge over oil hole.

Special tool

(A): 09900–22301 (Plastigauge (0.025 –

0.076 mm))

I9J011140249-01

I9J011140250-01

1. Conrod bearing 2. Dowel pin

I9J011140071-01

I9J011140251-01

I9J011140252-02

Loading...

Loading...