Fuel System: 1G-16

Fuel Leakage Check Procedure

Z9J0111706004

After performing any fuel system service, always be sure

there is no fuel leakage by checking as follows.

1) Squeeze fuel primer bulb until you feel resistance.

2) Shift into “Neutral” position.

3) Ensure emergency stop switch lock plate is in place.

4) Turn ignition switch “ON” for 3 seconds (to operate

fuel pump), then turn it “OFF”.

Repeat this (“ON” and “OFF”) procedure 3 or 4 times

to pressurize the fuel system.

5) Once pressurized, check all connections and

components for any signs of leakage.

Inspection of Fuel Hose Connections

Z9J0111706005

Note that the fuel hose connection varies with each type

of pipe. Be sure to connect and clamp each hose

correctly by referring to the figure.

• For type “A” (short barbed end) pipe, the hose must

completely cover pipe.

Type “A”

• For type “B” (bent end) pipe, hose must cover the

straight part of pipe by 20 – 30 mm (0.8 – 1.2 in.).

Type “B”

• For type “C” pipe, hose must fit up against the flanged

part of pipe.

Type “C”

• For type “D” pipe, the hose must cover the pipe by 20

– 30 mm (0.8 – 1.2 in.).

Type “D”

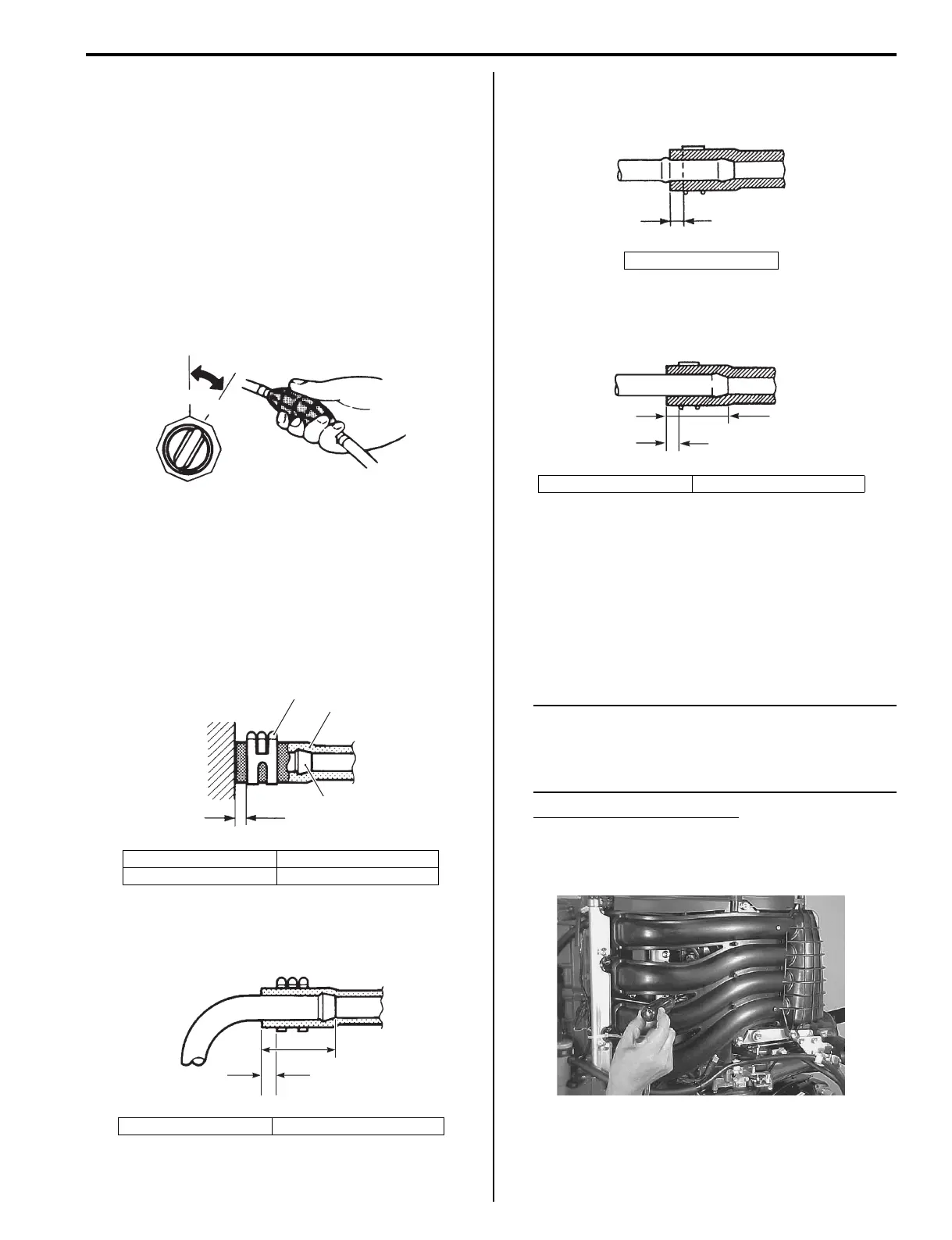

High Pressure Fuel Pump Operating Sound

Inspection

Z9J0111706006

1) Install the emergency stop switch lock plate into

position.

2) Shift into “Neutral”.

3) Turn ignition switch “ON” and check for fuel pump

operating sound.

NOTE

Fuel pump operating sound is low because

the pump is inside the fuel vapor separator. If

you cannot hear the pump sound clearly, use

a sound scope or long blade screw driver.

Fuel pump operating sound

Sounds for approx. 3 seconds only

(each time the ignition is turned to the “ON”

position)

1. Clamp (Clip) 3. Joint pipe

2. Hose “a”: 3 – 7 mm (0.1 – 0.3 in)

“a”: 3 – 7 mm (0.1 – 0.3 in) “b”: 20 – 30 mm (0.8 – 1.2 in)

OFF

ON

I9J011170020-01

1

2

3

“a”

I9J011170012-01

“a”

“b”

I9J011170013-01

“a”: 3 – 7 mm (0.1 – 0.3 in)

“a”: 3 – 7 mm (0.1 – 0.3 in) “b”: 20 – 30 mm (0.8 – 1.2 in)

“a”

I9J011170014-01

“a”

“b”

I9J011170015-01

I9J011170031-01

Loading...

Loading...