Power Unit Mechanical: 1D-38

Valve head radial runout

Measure valve head radial runout.

To measure runout, rotate valve slowly.

If measurement exceeds service limit, replace valve.

Special tool

(A): 09900–20606 (Dial gauge)

(B): 09900–21304 (Steel “V” block set)

: 09900–20701 (Magnetic stand)

Valve head radial runout

Service limit: 0.08 mm (0.0031 in.)

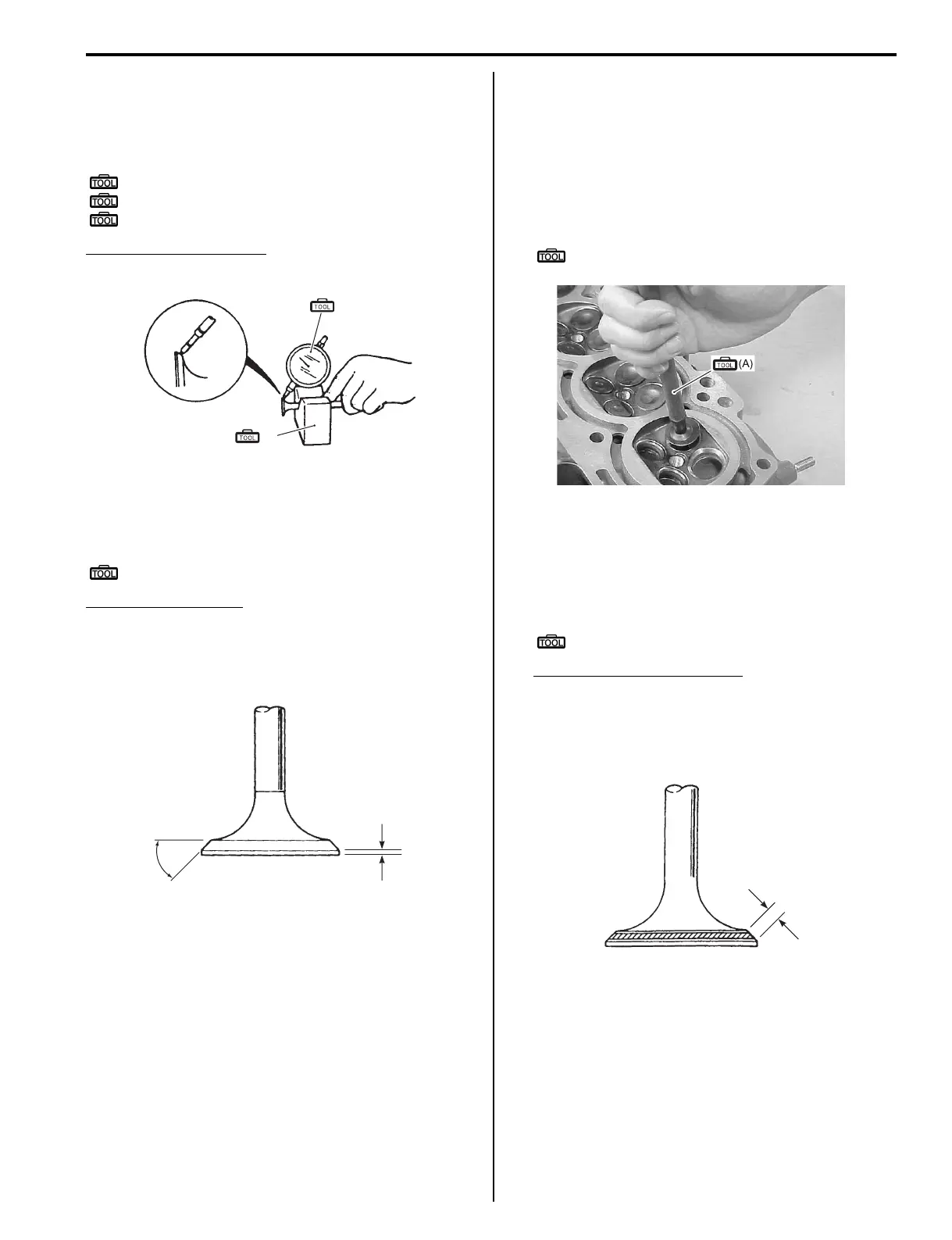

Valve head thickness

Measure thickness “a” of valve head.

If measurement exceeds service limit, replace valve.

Special tool

: 09900–20101 (Vernier calipers (150 mm))

Valve head thickness

Standard (IN.): 0.75 mm (0.03 in.)

Standard (EX.): 0.95 mm (0.04 in.)

Service limit (IN.): 0.5 mm (0.02 in.)

Service limit (EX.): 0.7 mm (0.03 in.)

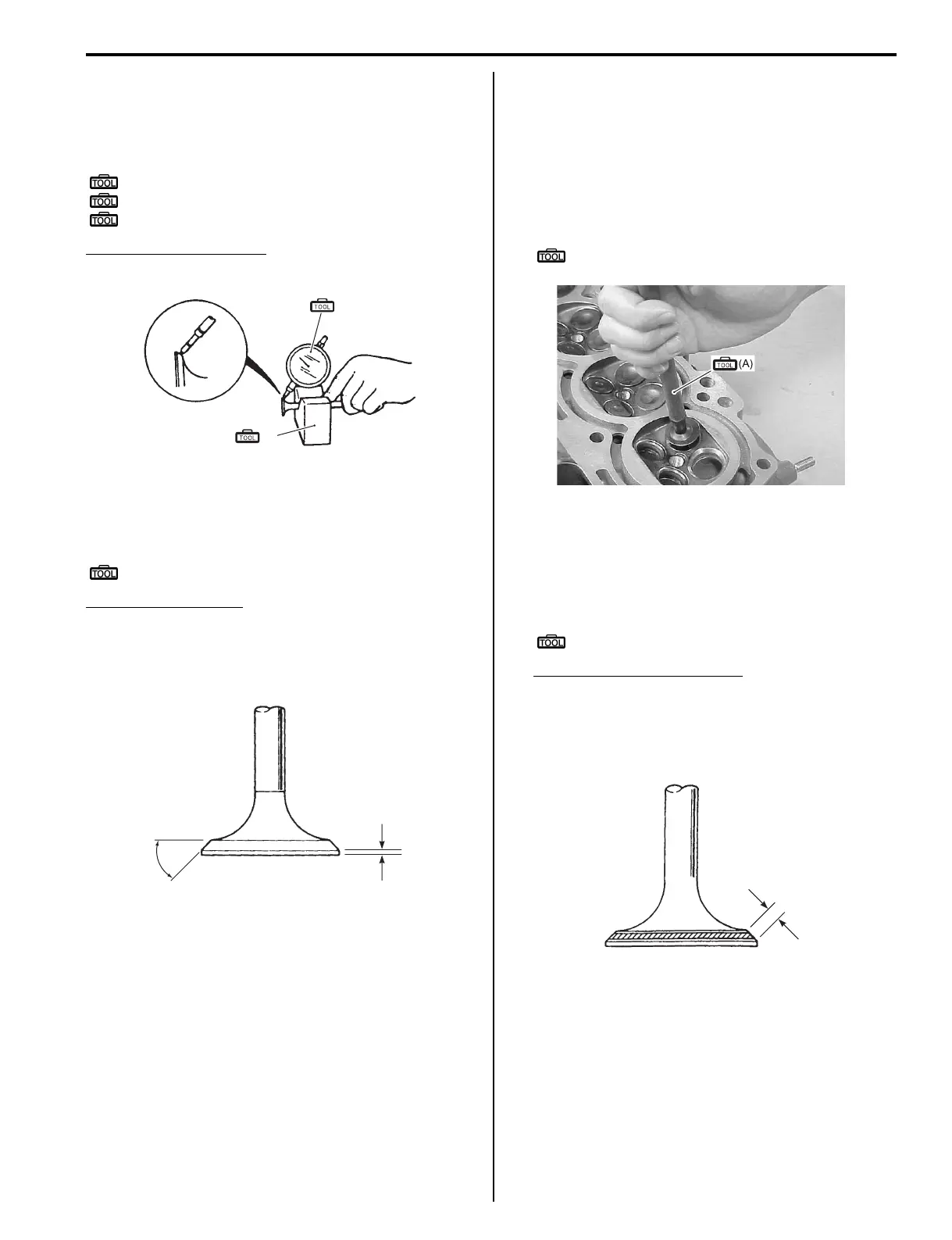

Valve seat contact width

Measure valve seat contact width as follows:

1) Remove all carbon from valve and seat.

2) Coat valve seat evenly with prussian blue (or

equivalent).

3) Install valve into valve guide.

4) Put valve lapper on valve.

Special tool

(A): 09916–10911 (Valve lapper)

5) Rotate valve while gently tapping valve contact area

against seat.

6) Continue until a pattern is on valve seat face with

prussian blue.

7) Measure valve seat contact width “b”.

Special tool

: 09900–20101 (Vernier calipers (150 mm))

Valve seat contact width “b”

Standard (IN., EX.): 1.1 – 1.3 mm (0.0433 – 0.0512

in.)

If measurement exceeds specification, repair valve

seat. Refer to “Valve seat servicing” (Page 1D-39).

(A)

(B)

I9J011140043-03

45°

“a”

I9J011140044-01

I9J011140219-01

“b”

I9J011140045-01

Loading...

Loading...