Power Unit Mechanical: 1D-48

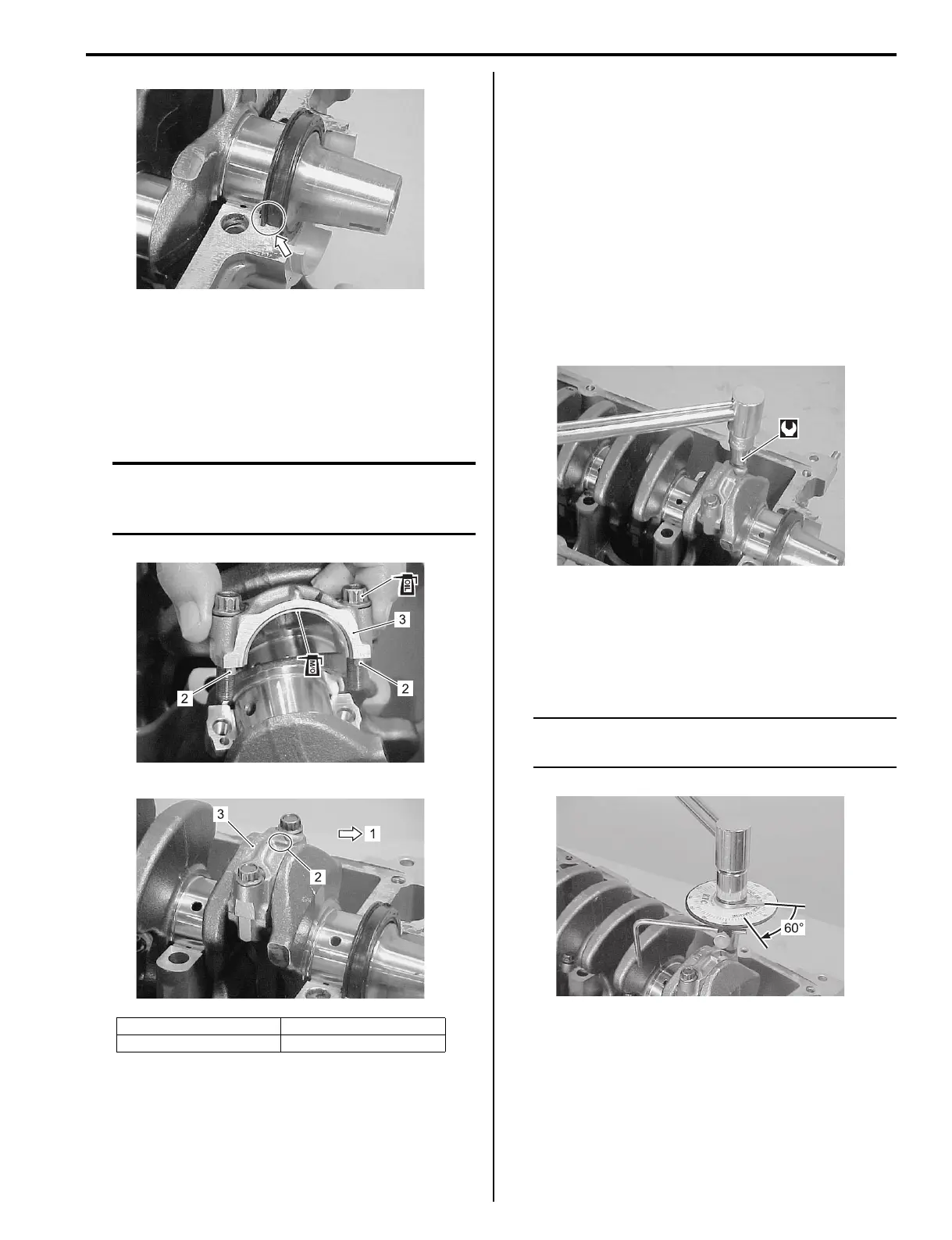

3) Install conrod cap.

a) Apply molybdenum oil solution to crank pin and

conrod bearing.

b) Install dowel pins (2) and conrod cap (3) (with

bearing) to conrod with embossed mark on the

cap toward flywheel side.

CAUTION

Reassemble each conrod cap to its original

position.

Do not mix them in position.

4) Apply engine oil to conrod bolts.

Tighten conrod cap bolts in three steps as follows.

a) Lightly seat all conrod bolts at first, then tighten

bolts 12 N⋅m (1.2 kgf-m, 8.7 lbf-ft) of specified

torque.

Tightening torque

Conrod cap bolt (1st step): 12 N·m (1.2 kgf-

m, 8.7 lbf-ft)

b) Tighten bolts 17 N⋅m (1.7 kgf-m, 12.3 lbf-ft) of

specified torque.

Tightening torque

Conrod cap bolt (2nd step): 17 N·m (1.7 kgf-

m, 12.3 lbf-ft)

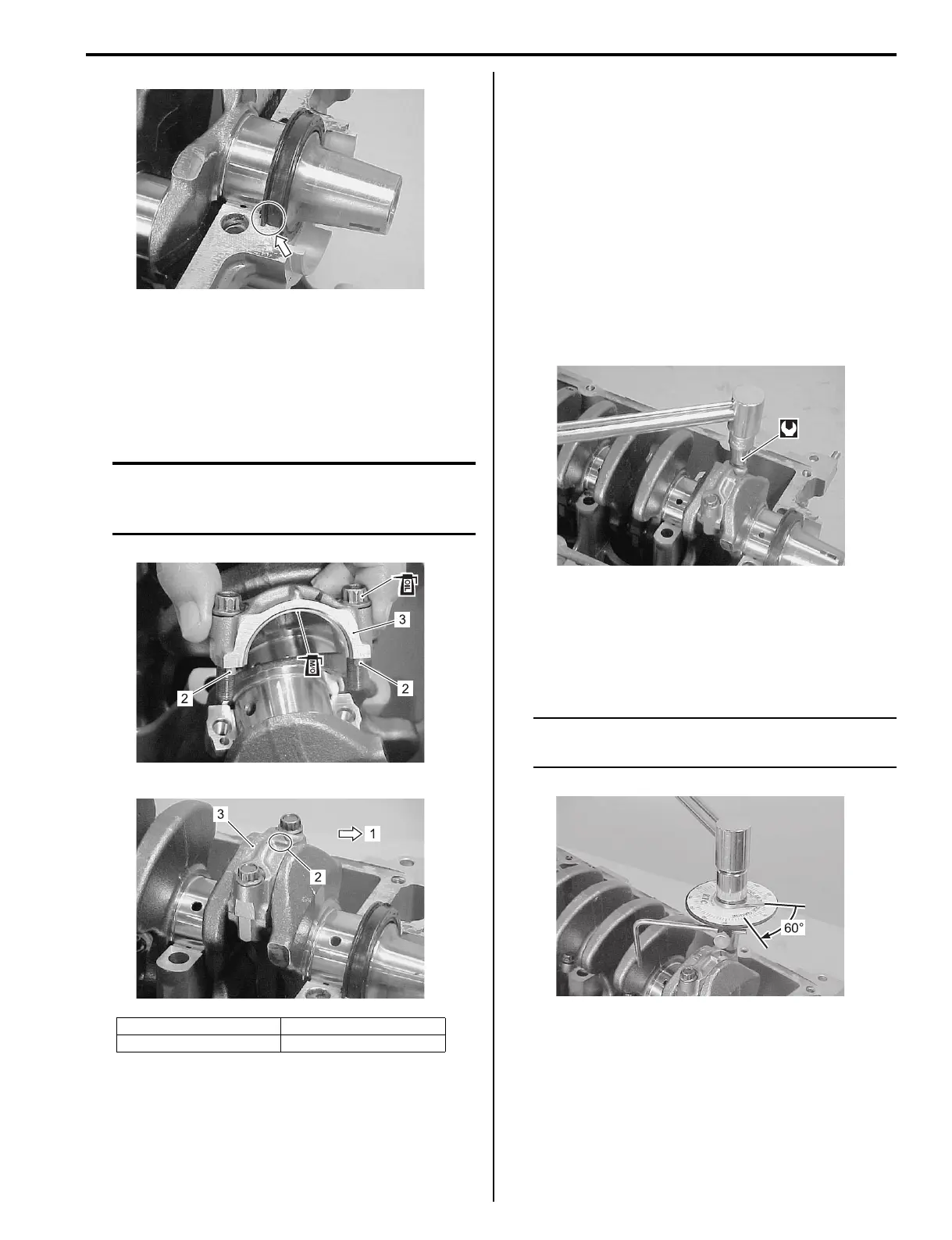

c) Finally tighten bolts 60 degrees turn from the

point of step (b) using an angular torque gauge.

Tightening torque

Conrod cap bolt (Final step): 60 degrees (47

N⋅m, 4.7 kgf-m, 34 lbf-ft)

NOTE

Purchase a commercially available angular

torque gauge for this step of tightening bolts.

d) Pour approx. 2 ml of engine oil to each side

surface of the conrod big end for initial

lubrication.

1. Flywheel side 3. Conrod cap

2. Embossed mark

I9J011140235-02

I9J011140236-01

I9J011140237-01

I9J011140238-01

I9J011140239-03

Loading...

Loading...